A dual-diaphragm speaker module

A loudspeaker module and loudspeaker technology, applied in the direction of loudspeaker transducer fixation, diaphragm fixation/tightening, sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

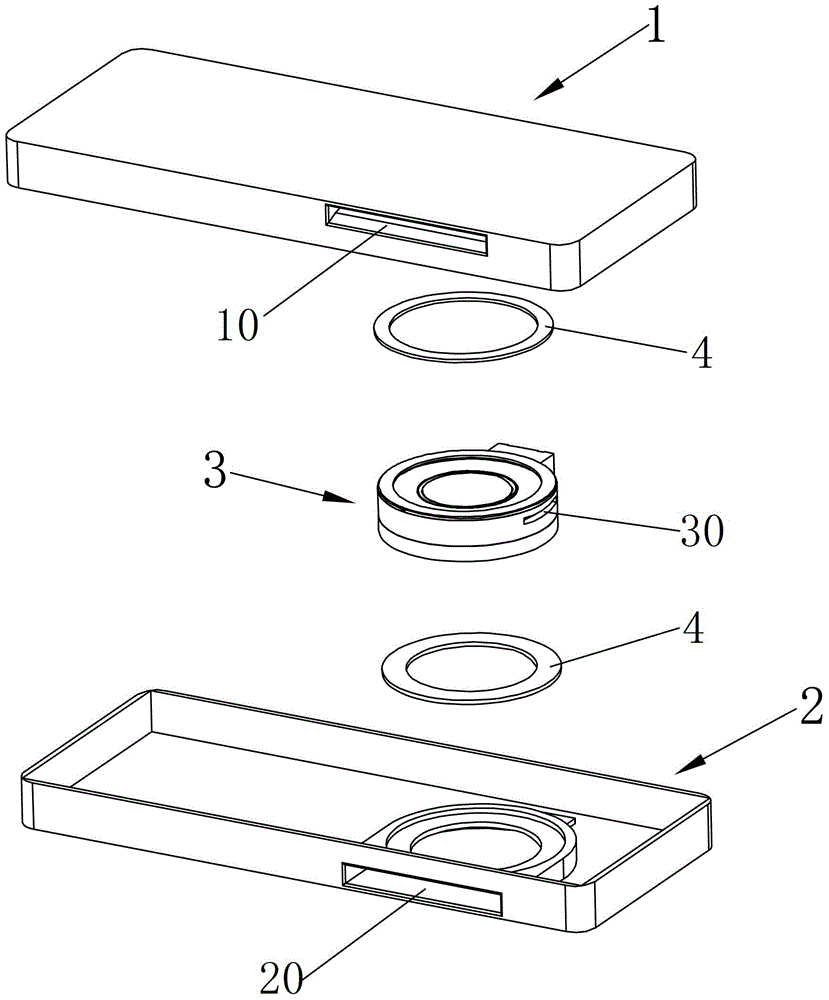

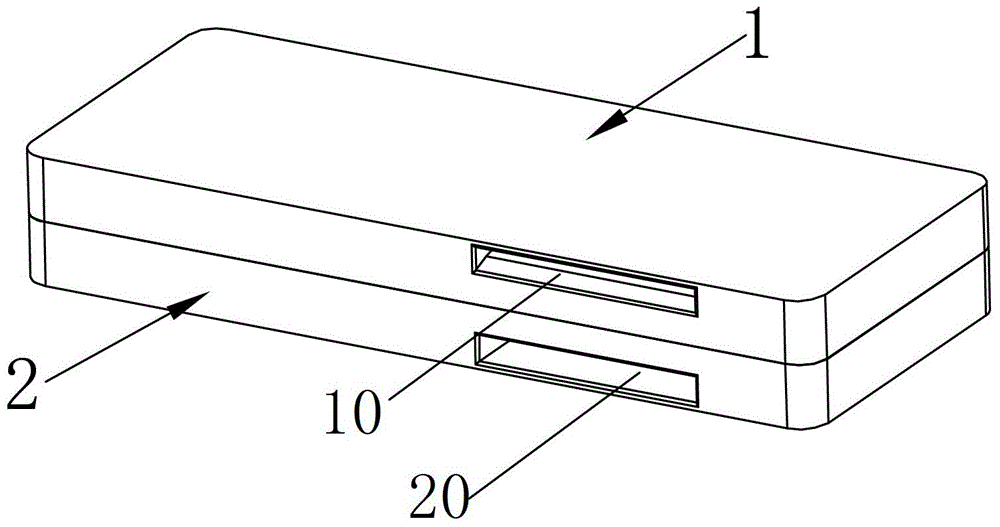

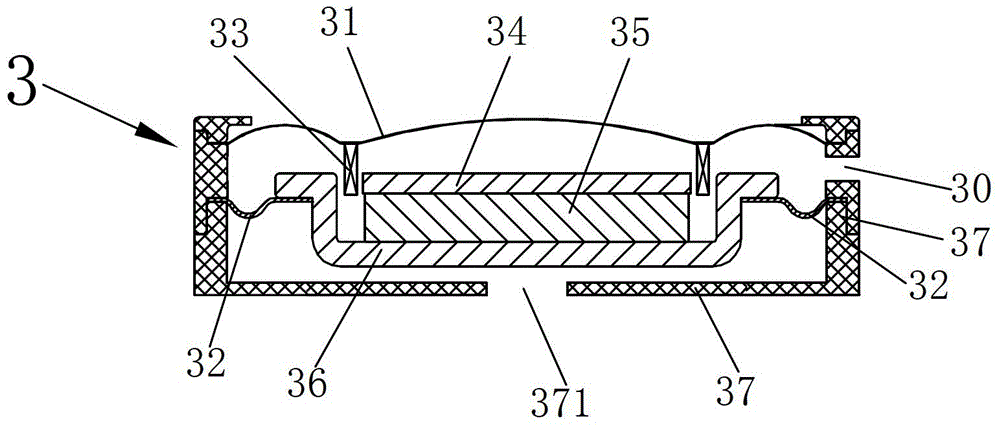

[0027] like figure 1 and figure 2 As shown, the loudspeaker module of the present invention includes a loudspeaker unit 3 and a peripheral housing that accommodates and fixes the loudspeaker unit 3, wherein the upper surface and the lower surface of the loudspeaker unit 3 that are fixedly combined with the peripheral housing are also respectively combined with elastic buffers. Part 4, the elastic buffer part 4 in this embodiment can be foam or spring pad. In order to facilitate the assembly of the speaker module, the peripheral casing is divided into two independent parts: the first casing 1 and the second casing 2. During the assembly process, the speaker unit 3 and the elastic buffer 4 can be combined with the first casing 1. (or the second shell 2) after assembly, then the second shell 2 (or the first shell 1) is combined with the first shell 1 (or the second shell 2), and then glued or ultrasonically welded The first housing 1 and the second housing 2 are fixedly combin...

Embodiment 2

[0037] like Figure 6 and Figure 7 As shown, the speaker module of this embodiment includes a speaker unit 3 , an outer casing for accommodating and fixing the speaker unit 3 , and elastic buffers 4 combined with the edges of both sides of the speaker unit 3 . The peripheral shell is divided into two parts: the first shell 1' and the second shell 2; the main difference between this embodiment and the first embodiment is that the first sound hole 10' is set on the first shell 1' On the surface, the side of the second housing 2 is provided with a second sound hole 20 . In addition, the side of the speaker unit 3 is also provided with a sound leakage hole 30 connecting the rear acoustic cavity of the speaker module and the inner side of the speaker unit 3 . In this embodiment, the first sound outlet 10' is divided into a plurality of strip structures by the outer casing, and this structure has a better dustproof effect. Preferably, the first sound outlet 10' is located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com