Extirpator capable of using tractor to output power to drive weeding tooth assembly to rotate

A power drive, tractor technology, applied in the direction of agricultural machinery, agricultural machinery and implements, applications, etc., can solve the problems of the rotation speed of the weeding tooth assembly, the speed of the weeding tooth assembly can not be guaranteed, and the quality of the weeding can not be guaranteed, so as to achieve good operation quality, high production efficiency, Use reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

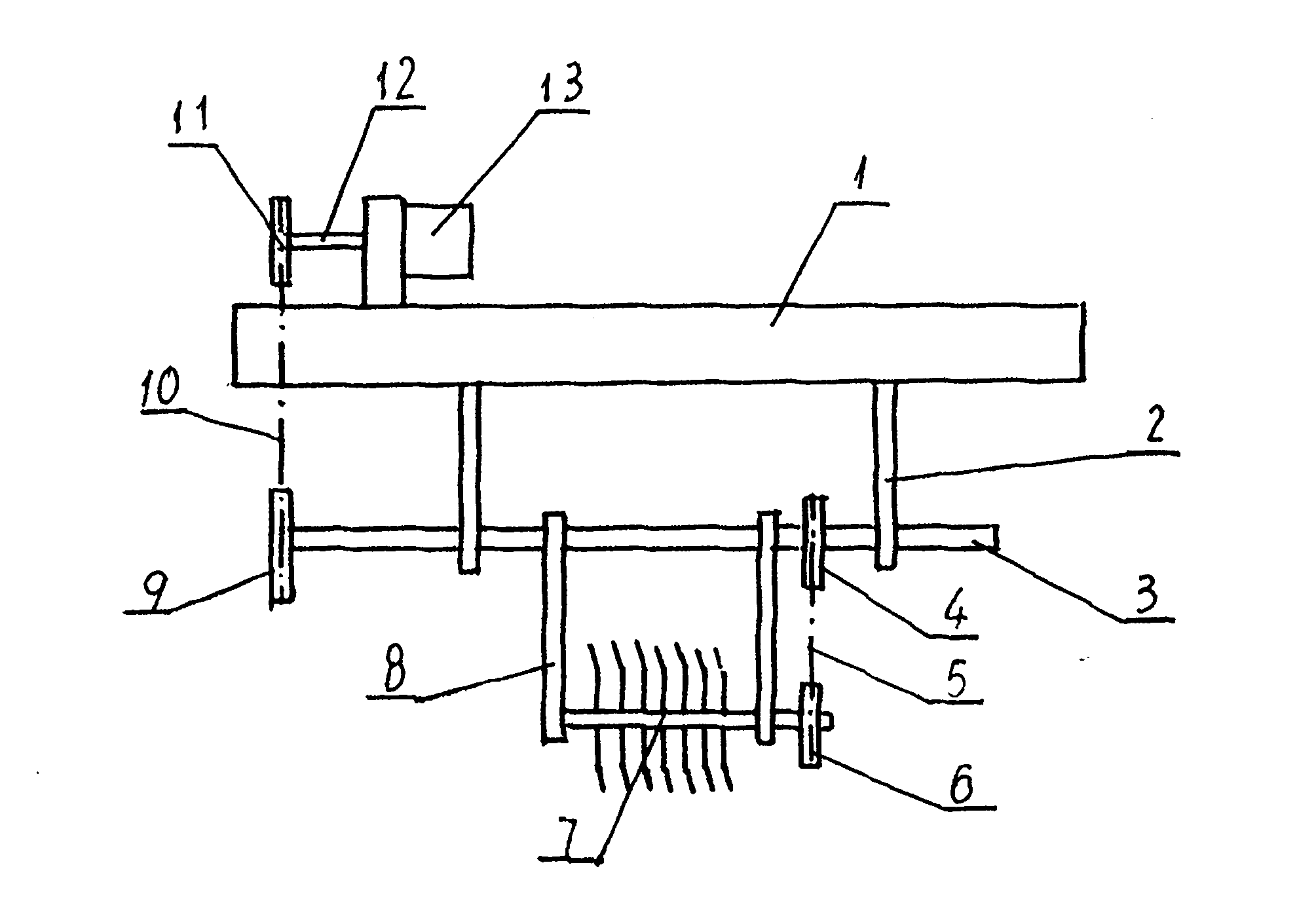

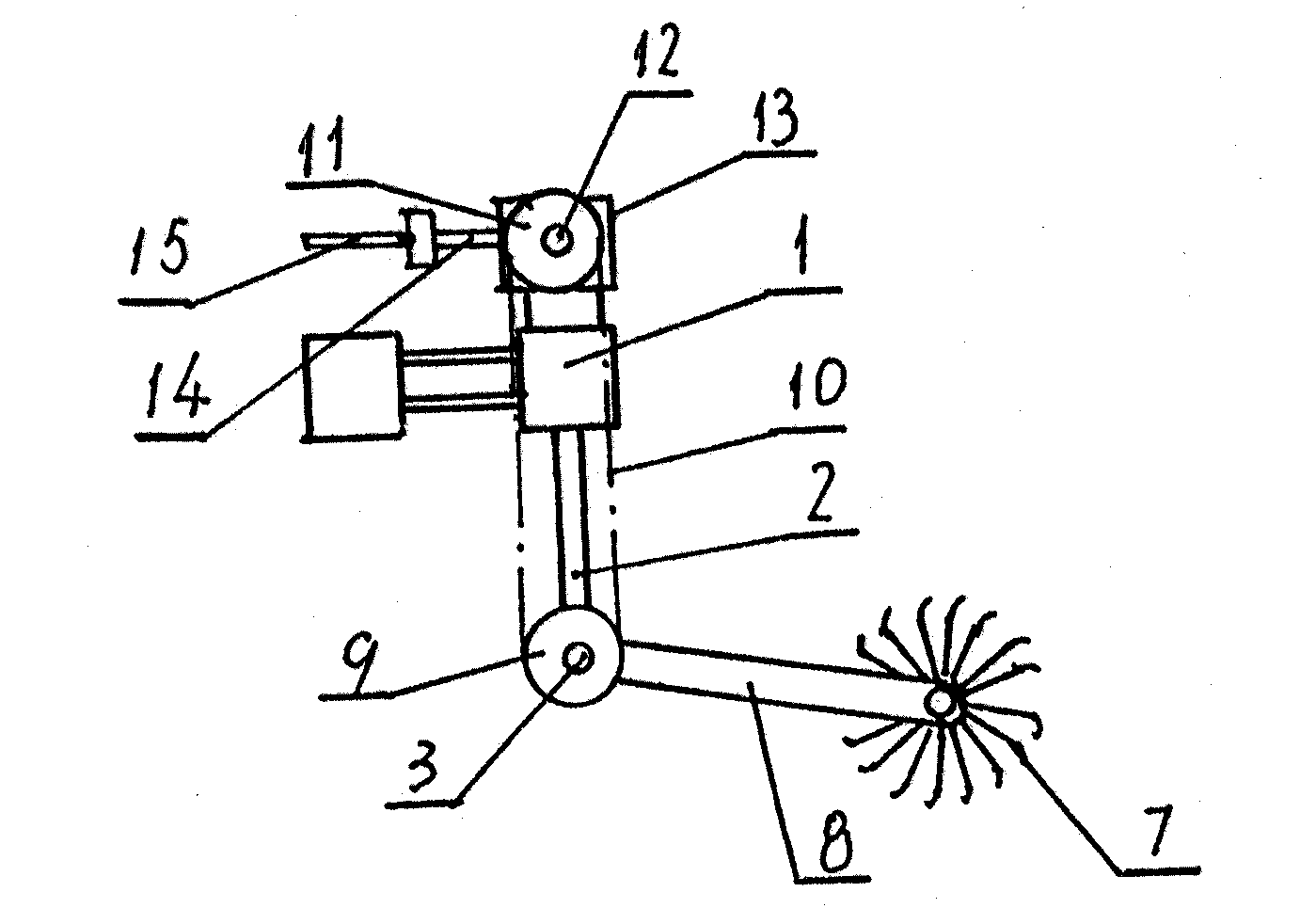

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A cultivator and weeder that drives the rotation of the weeding tooth assembly by the output power of the tractor. 8 is hingedly installed on the main drive shaft 3, and the transmission box 13 is fixed on the frame assembly 1, and the universal joint transmission shaft 15 and the second A sprocket 11, the second sprocket 9 and the third sprocket 4 are fixed on the main drive shaft 3, the fourth sprocket 6 is fixed on the weeding tooth assembly 7, and the first chain 10 is set on the first sprocket 11 and the second sprocket 9, the second chain 5 is sleeved on the third sprocket 4 and the fourth sprocket 6.

[0011] During operation, the whole machine is hung on the rear part of the tractor, and the transmission box 13 is communicated with the output power of the tractor by utilizing the cardan shaft 15 to get final product. The output power of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com