Disc-shaped panel leveling device and disc-shaped panel leveling method

A leveling and disc-shaped technology, which is applied in the field of aircraft brake disc frame warpage exceeding the standard, can solve problems such as high leveling pressure, damage to the aircraft brake disc frame, easy rebound of the aircraft brake disc frame, etc., and achieves the installation and disassembly method Simple, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

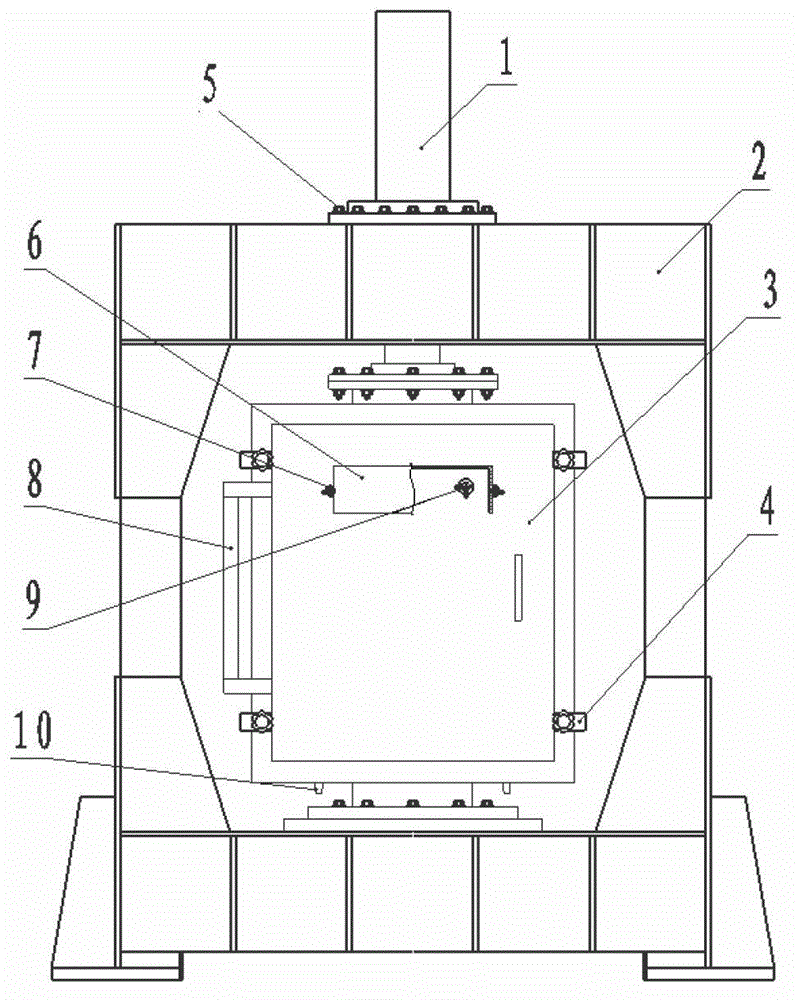

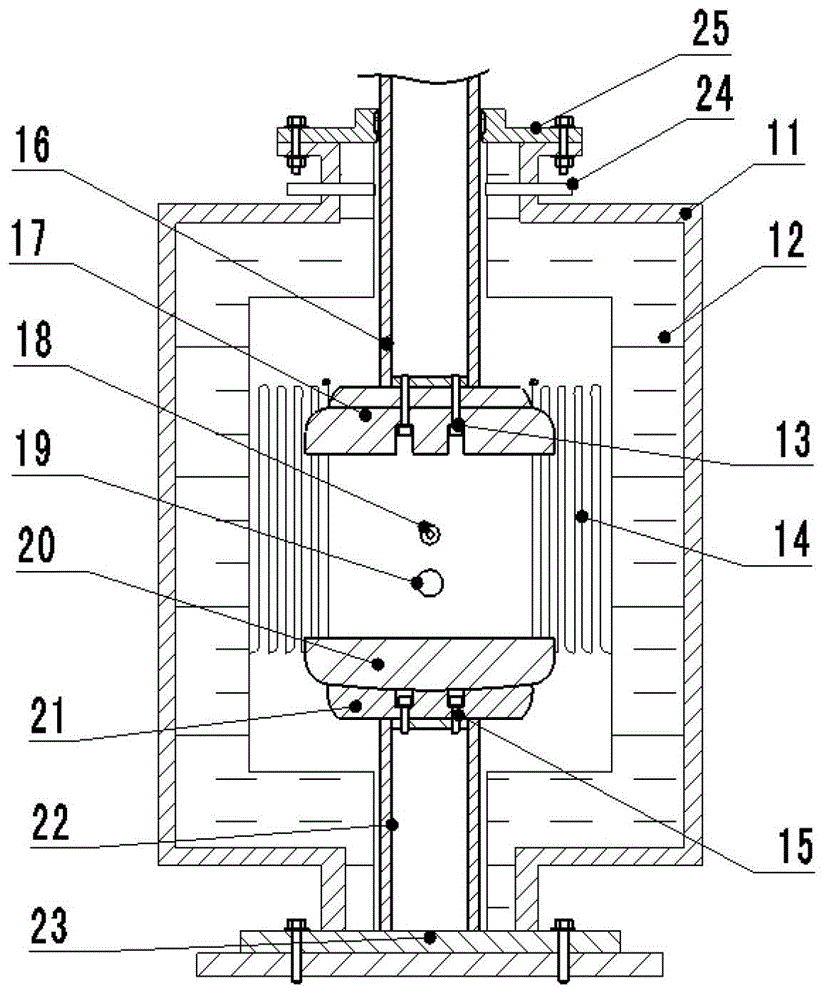

[0044]This embodiment is a leveling device for a disc-shaped plate, including a hydraulic cylinder 1, a gantry frame 2, a furnace body 11, a heat preservation furnace lining 12, an electric furnace wire 14, a hydraulic cylinder piston 16, an upper pressure head 17, a thermocouple 18, a lower Indenter 20, parallelism adjustment table 21, bearing column 22 and furnace body base 23.

[0045] Gantry 2 is the carrier of the present embodiment. The portal frame 2 is a frame structure, including a pillar, an upper beam, a furnace body mounting platform 28 and a portal frame base. The upper beam and the furnace body installation platform 28 are rectangular. Between the upper crossbeam and the body of furnace installation platform 28, it is supported by a pillar, and the base is installed on the lower crossbeam for supporting the whole device.

[0046] There is a hydraulic cylinder installation hole at the geometric center of the upper beam, and the hydraulic cylinder 1 is fixed in t...

Embodiment 2

[0059] This embodiment is a method for leveling the brake disc frame of a certain type of aircraft by using the disc leveling device described in Example 1. The specific process is:

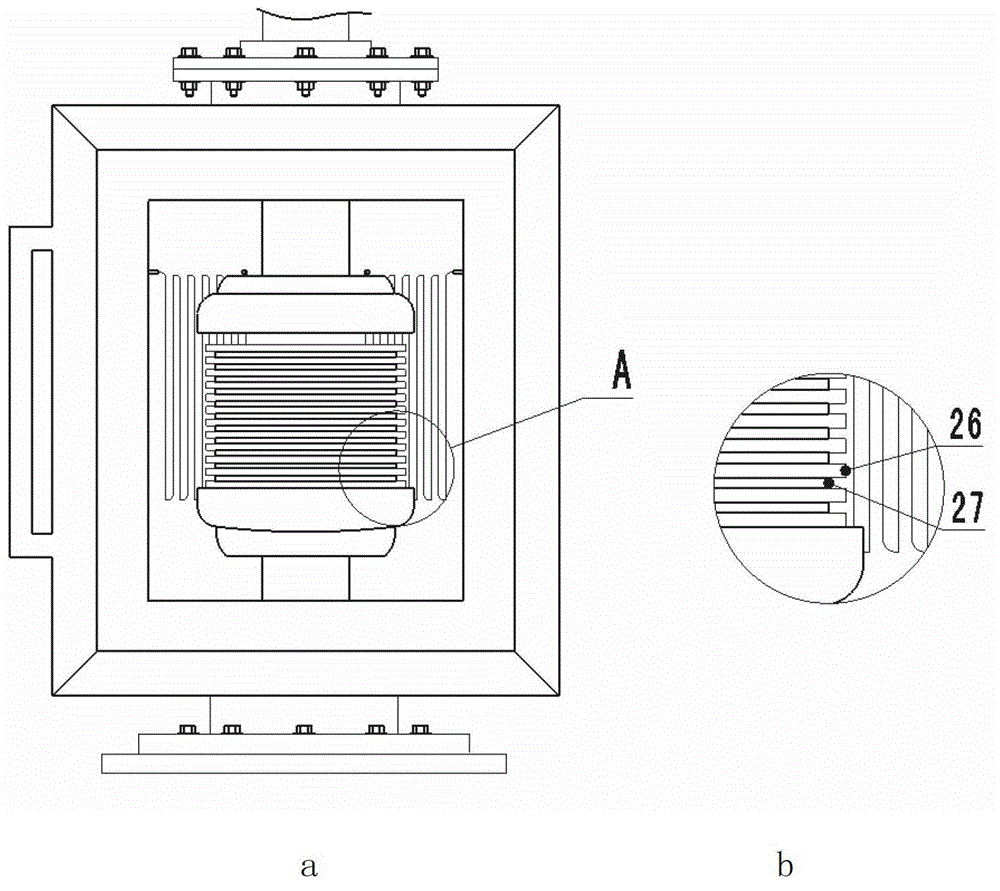

[0060] Step 1, install the brake disc frame 27 and backing plate 26 of the aircraft to be leveled. Such as image 3 As shown, first unscrew the C-shaped clamp 4, open the furnace door, lift the upper pressure head 17 through the external hydraulic control system, adjust the relay in the control cabinet to control the hydraulic valve in the hydraulic station, and discharge oil and pressure on the hydraulic cylinder 1 , so that the hydraulic cylinder piston 16 drives the upper pressure head 17 to lift 260mm according to the number of required leveling workpieces, then place a backing plate 26 on the lower pressure head 20, and then place a piece of aircraft brake disc to be leveled in the middle of the backing plate 26 in turn Skeleton27. During installation, the backing plate 26, the aircraft br...

Embodiment 3

[0072] This embodiment is a method for leveling the brake disc skeleton of a certain type of aircraft. The specific process is:

[0073] Step 1, install the brake disc frame 27 and backing plate 26 of the aircraft to be leveled. Such as image 3 As shown, first unscrew the C-shaped clamp 4, open the furnace door, lift the upper pressure head 17 through the external hydraulic control system, adjust the relay in the control cabinet to control the hydraulic valve in the hydraulic station, and discharge oil and pressure on the hydraulic cylinder 1 , so that the hydraulic cylinder piston 16 drives the upper pressure head 17 to lift, and the lifting height of the upper pressure head is determined according to the number of required leveling workpieces. A backing plate 26 is placed on the lower pressing head 20, and a piece of aircraft brake disc skeleton 27 to be leveled is placed in the middle of the backing plate 26 successively. During installation, the backing plate 26, the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com