Special tool for foam concrete sandwich compound insulation building block subjected to post foaming forming

A technology of foam concrete and composite insulation, applied in the direction of molds, etc., can solve the problems that ordinary concrete blocks cannot meet the energy-saving requirements, the outer insulation layer of the outer wall is cracked, and the outer insulation layer falls off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

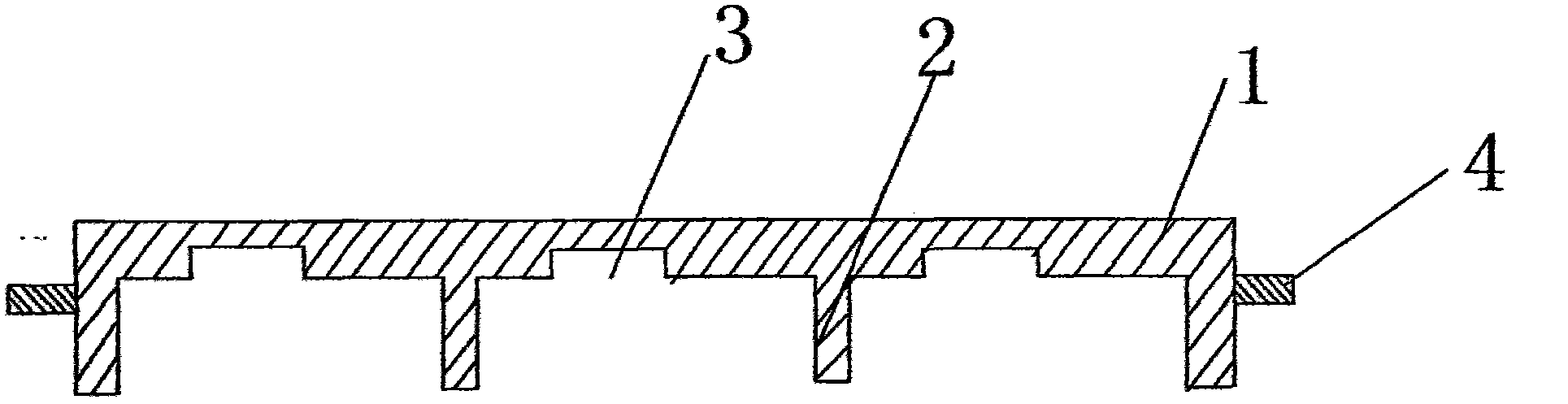

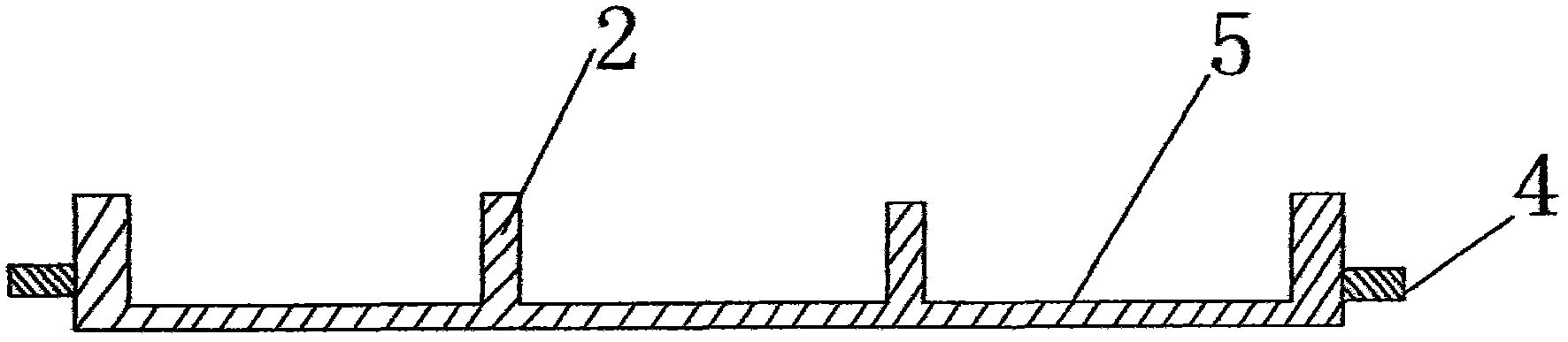

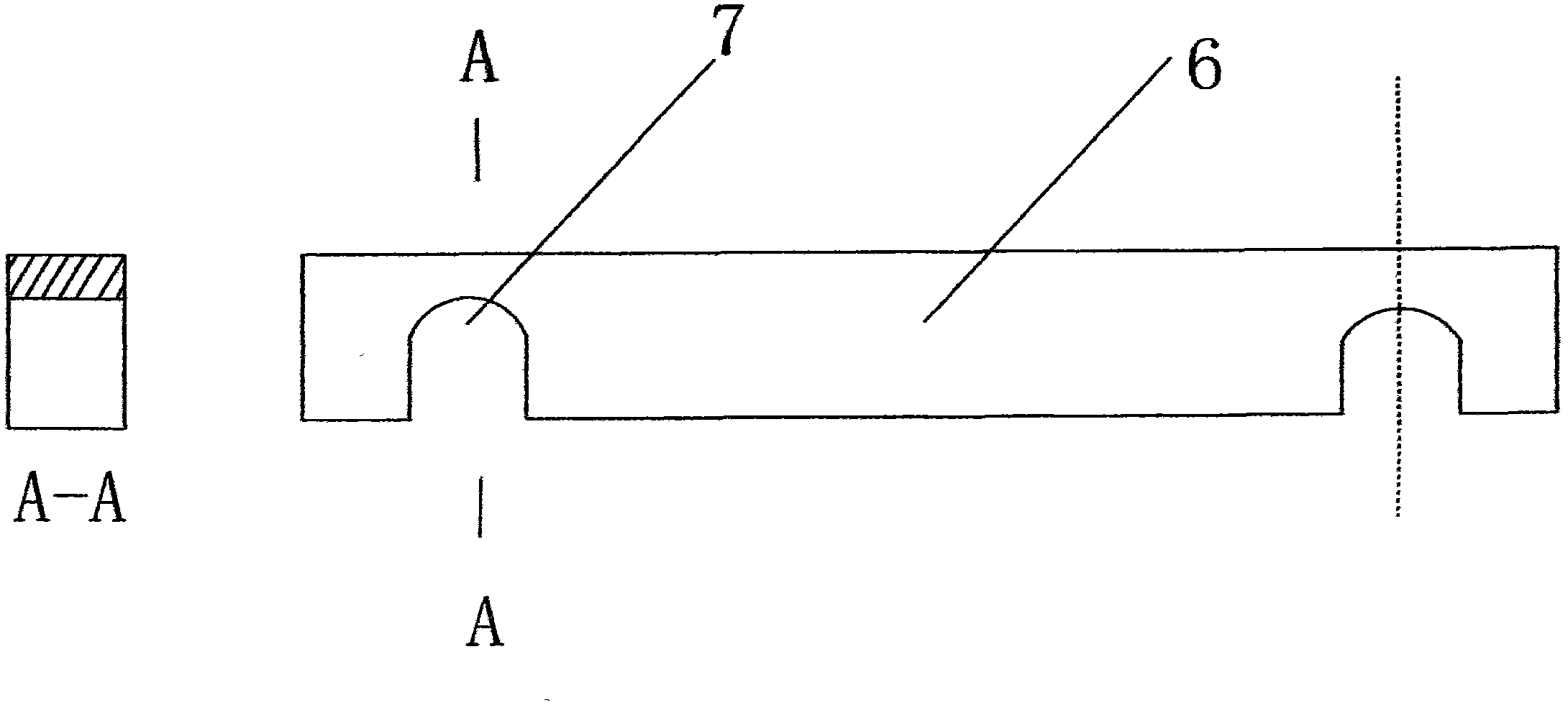

[0034] The present invention is achieved like this, below in conjunction with appendix Figure 1-Figure 10 , for further clarification:

[0035] (1) The concrete mixture is formed by the block forming machine, and the concrete outer leaf block 8 and the inner leaf block 9 are released from the mold of the block forming machine and fall on the supporting plate 11, and the chain conveyor drives the supporting plate 11 and Its upper product goes to the next station;

[0036] (2) Put the pull joint 13 in the female dovetail groove 15 of the outer leaf block 8 and the inner leaf block 9, and the chain conveyor drives the supporting plate 11 and the products on the upper part to the next station;

[0037] (3) The U-shaped outer baffle support plate 1 and the U-shaped inner baffle support plate 5 of the vertical groove 3 with a certain width are placed on the two sides of the prefabricated concrete outer leaf block 8 and the concrete inner leaf block 9 respectively. end, and closel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com