Top-mounted low temperature floating ball valve

A floating ball valve, low-temperature technology, applied to valve devices, engine components, cocks including cut-off devices, etc., can solve problems such as valve failure to open and close, valve seat and spherical valve core locked, affecting the sealing of spherical valve core and valve seat, etc. , to achieve the effect of simple processing method, stable performance and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

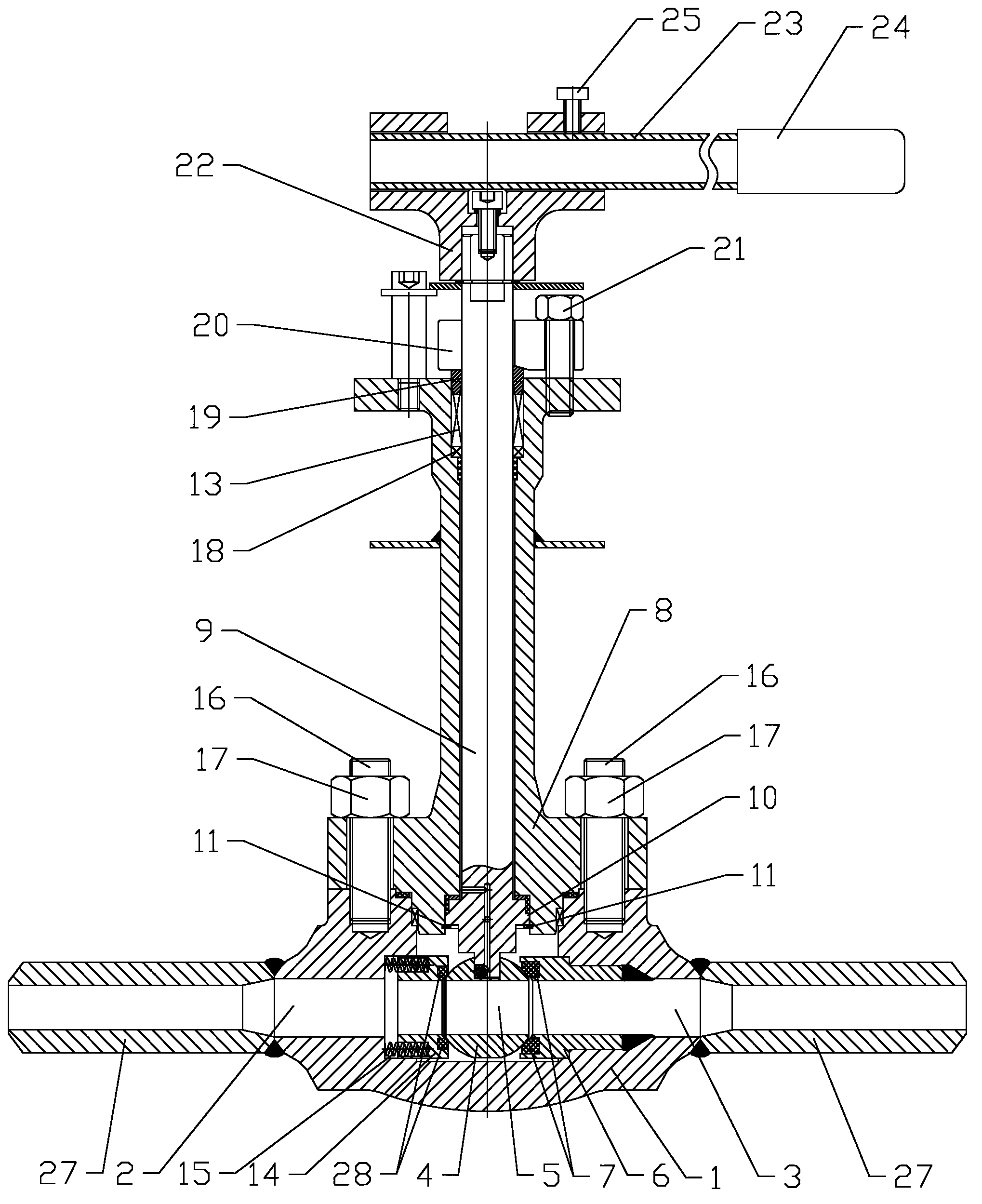

[0044] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

[0045] Such as Figure 2-4 Shown is a preferred embodiment of the top entry cryogenic floating ball valve of the present invention.

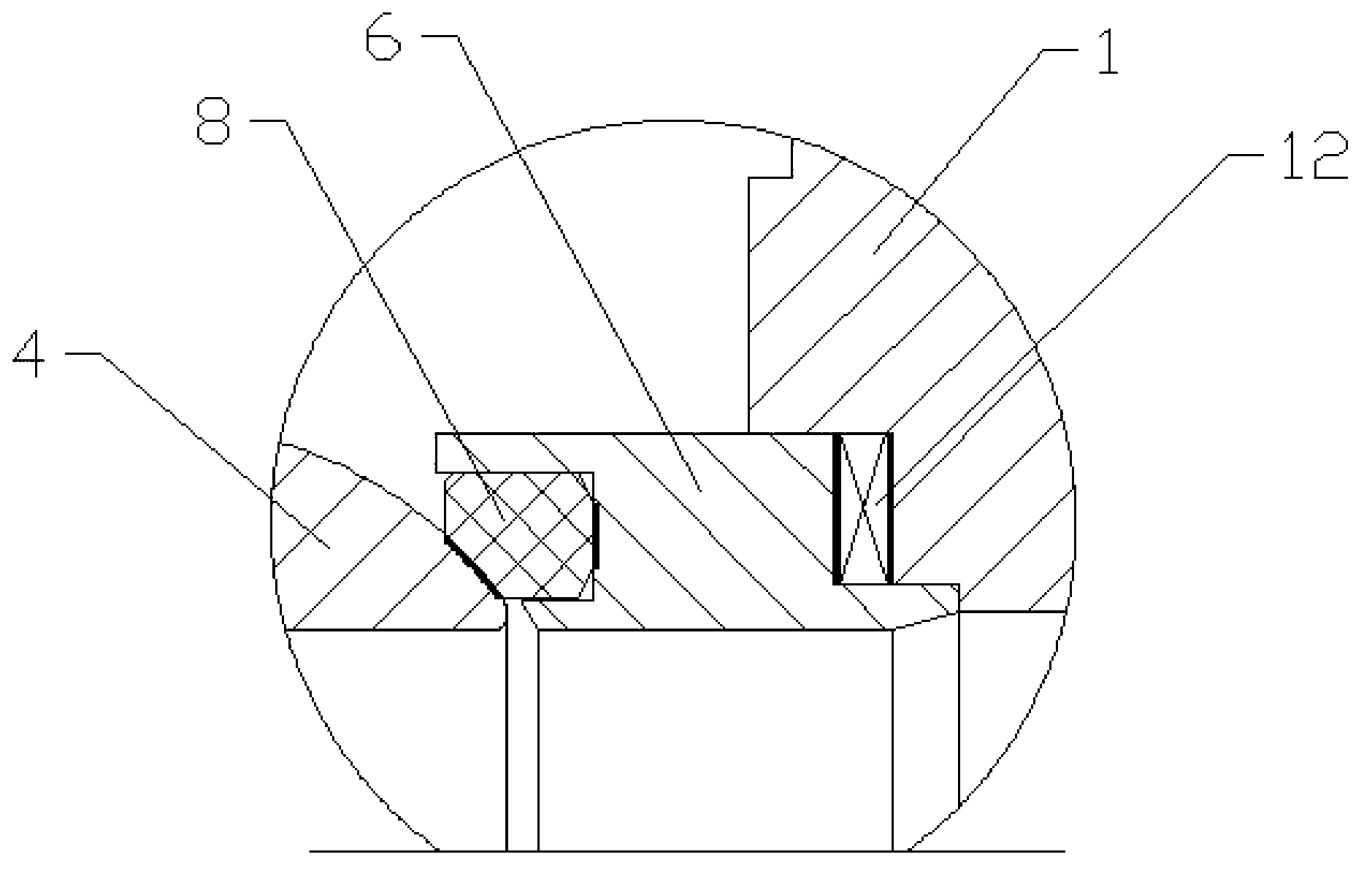

[0046] The top-entry low-temperature floating ball valve includes a valve body 1, a spherical valve core 4, a retainer 6, a valve cover 8, a valve stem 9, and the like.

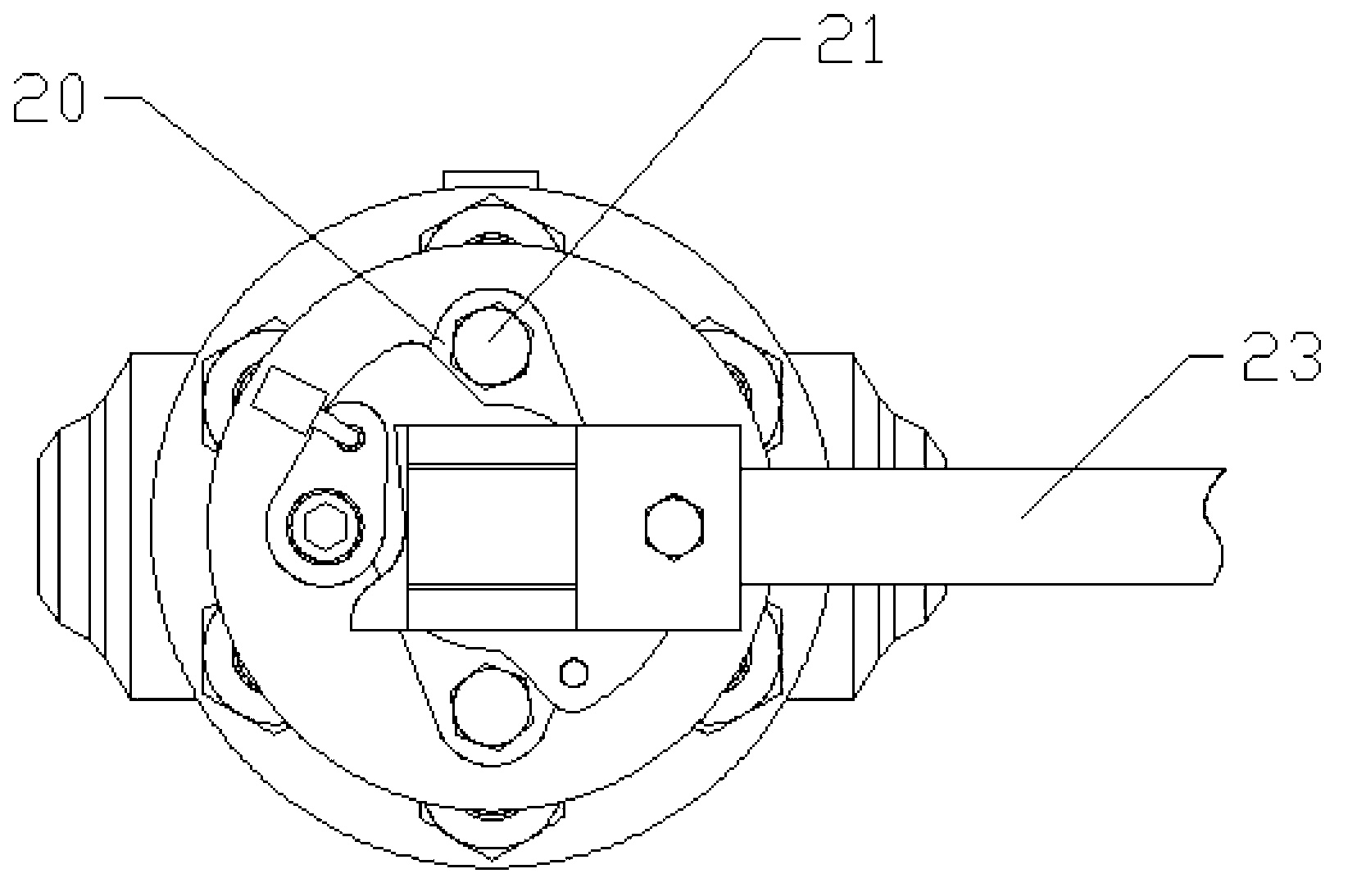

[0047] The valve body 1 has an inlet 2 and an outlet 3, and a cavity is formed inside the valve body 1, and the cavity communicates with the inlet 2 and the outlet 3, and the inlet 2 and the outlet 3 are suitable for The pipes 27 are butt welded. The upper part of the valve body 1 is detachably connected to the valve cover 8 through the cooperation of the studs 16 and the nuts 17. The upper part of the valve cover 8 is equipped with a handle 22, and the handle 22 is formed with a through hole. The hole is suitable for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com