Smelting furnace with conductor protection function

A wire protection and melting furnace technology, which is applied in the field of melting furnaces, can solve problems such as melting furnaces being unusable, cable damage and scrapping, and cable wear and tear, achieving good protection effects, prolonging service life, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

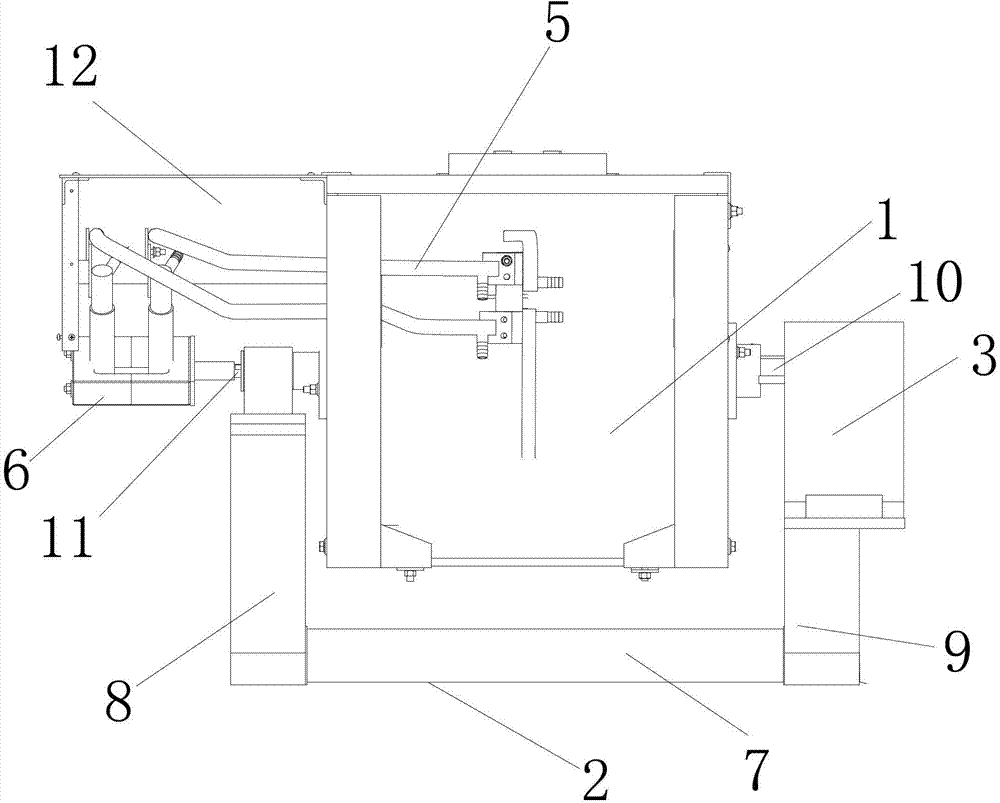

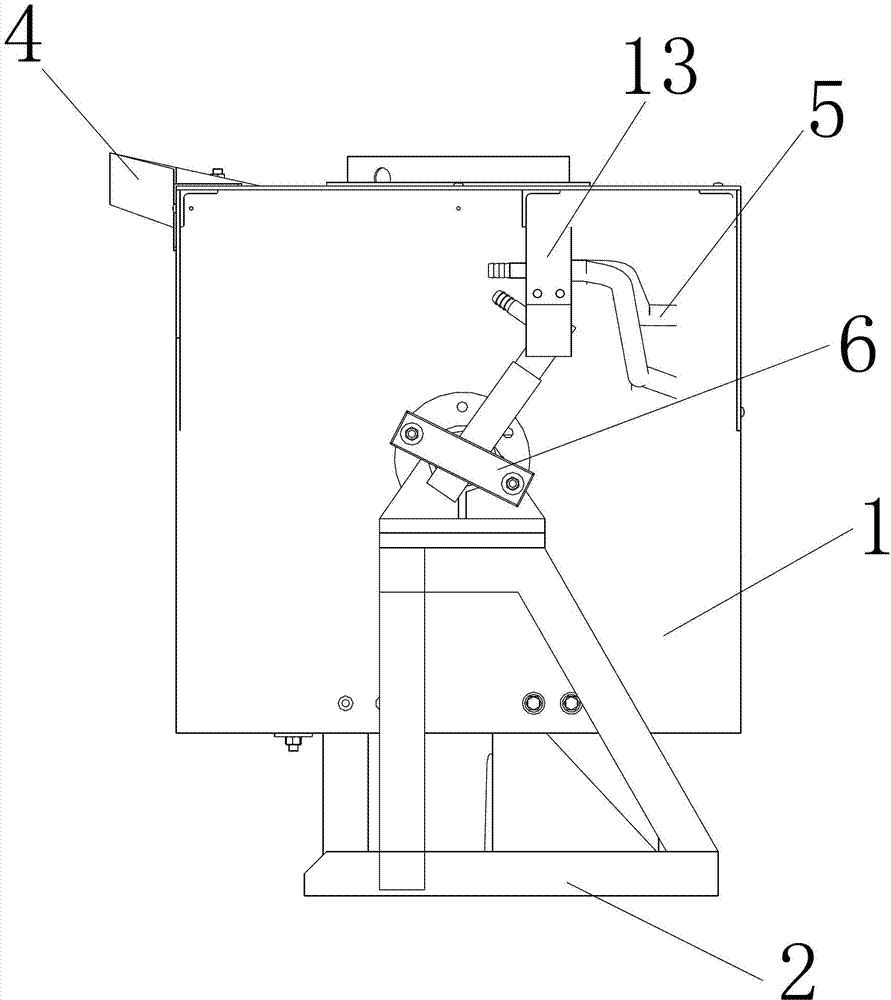

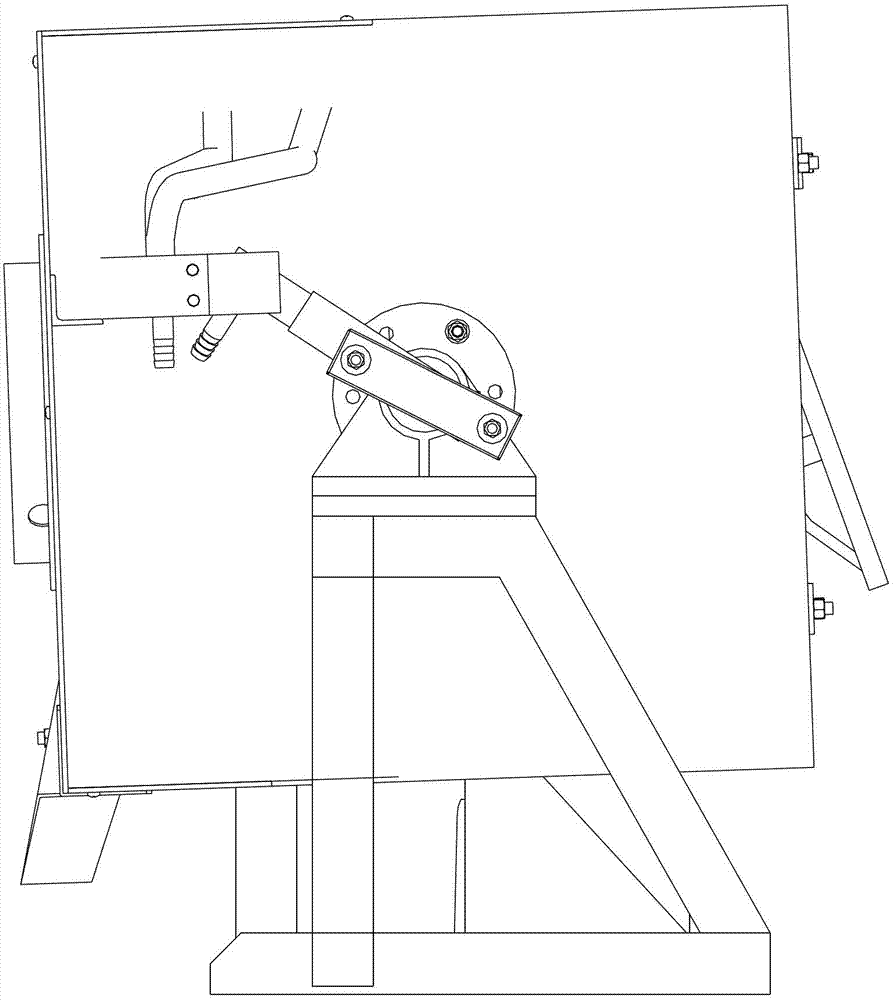

[0012] Such as Figure 1-4 As shown, a melting furnace with wire protection function includes a melting furnace body 1, a tilting frame 2, a reducer 3, a water-cooled cable, a protective sleeve 5, a rotating guide sleeve 6 and a protective plate 12, and the melting furnace body 1 A furnace nozzle 4 for pouring casting liquid is arranged on the top side panel, and the tilting frame 2 includes a base 7, a left support arm 8 and a right support arm 9, and a left support arm 8 and a right support arm 9 are respectively arranged on both sides of the base 7 , the length of the left support arm 8 is longer than the length of the right support arm 9 .

[0013] The melting furnace body 1 is arranged above the base 7, and the two side panels adjacent to the installation panel of the furnace nozzle 4 are located between the left support arm 8 and the right support arm 9 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com