Modified flexible substrate packaging device

A substrate sealing and flexible technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of large package volume, affecting the packaging and carrying of microelectronic substrates, and reducing the package volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

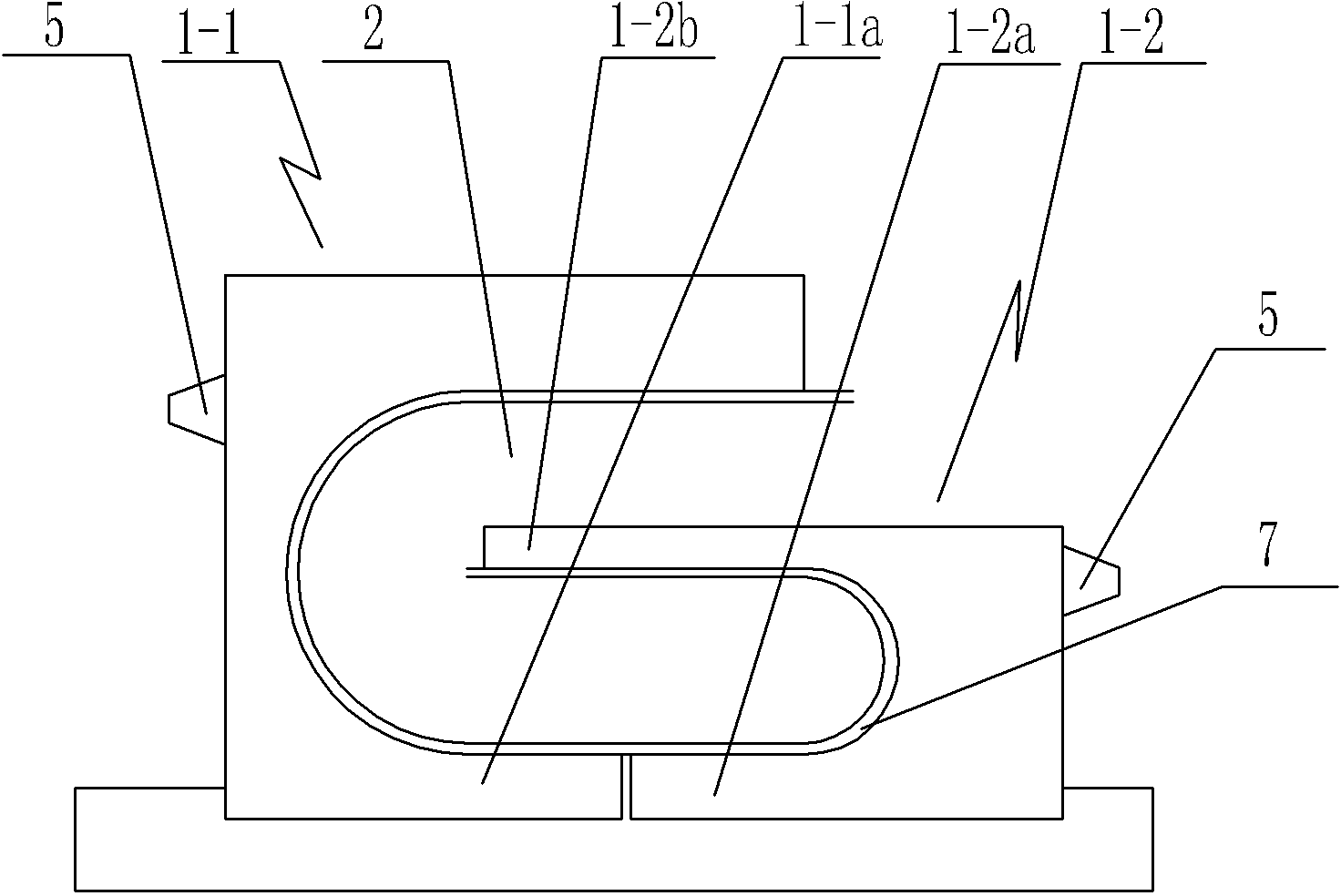

[0011] See figure 1 , figure 2 As shown, an improved flexible substrate packaging device includes U-shaped packaging heads 1-1 and 1-2 on both sides, and the U-shaped packaging heads 1-1 and 1-2 on both sides can move toward each other. The U-shaped packaging heads 1-1, 1-2 are not equal in size, one end 1-1a, 1-2a of the U-shaped packaging heads 1-1, 1-2 on both sides corresponds, and the other end 1-2b of the small packaging head corresponds to Recess 2 in the large package header corresponds.

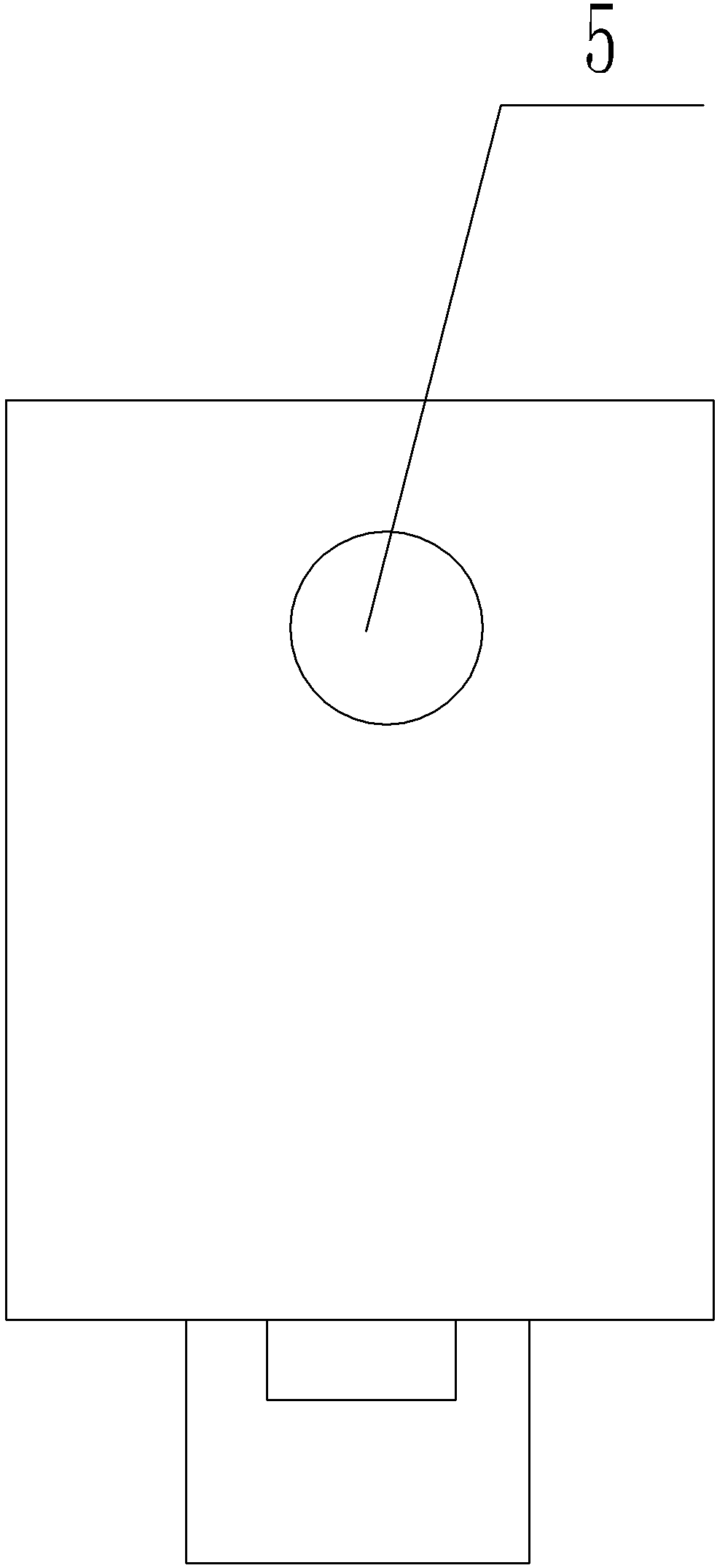

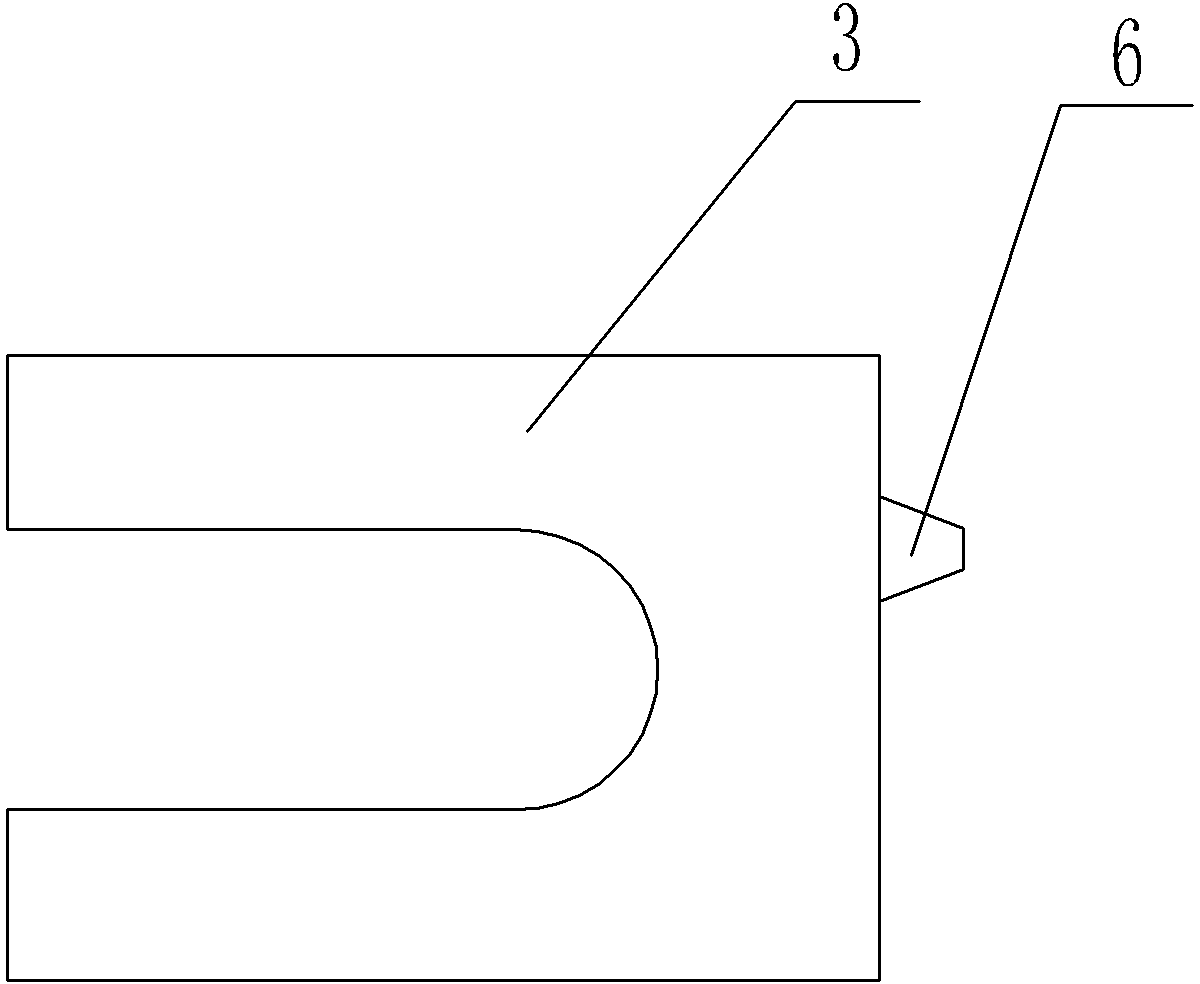

[0012] See figure 1 , figure 2 , image 3 , Figure 4 , the U-shaped packaging heads 1-1 and 1-2 are respectively provided with cavities 3, the inner side of the cavity 3 is provided with a through hole 4, and the outer side of the cavity 3 is provided with a suction port 5, which can ensure the stable suction of the flexible substrate Inside the U-shaped package head.

[0013] Due to the unequal size of the U-shaped packaging heads on both sides, through the relative moveme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap