Processing technology of mulberry leaf composite tea bag

A processing technology and a technology for compounding tea bags, which are applied in the field of tea processing technology, can solve the problems of being difficult to drink, the pure mulberry leaf tea has a strong grassy flavor, etc., and achieve the effects of improving body immunity, non-toxic and side effects, and pure soup color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

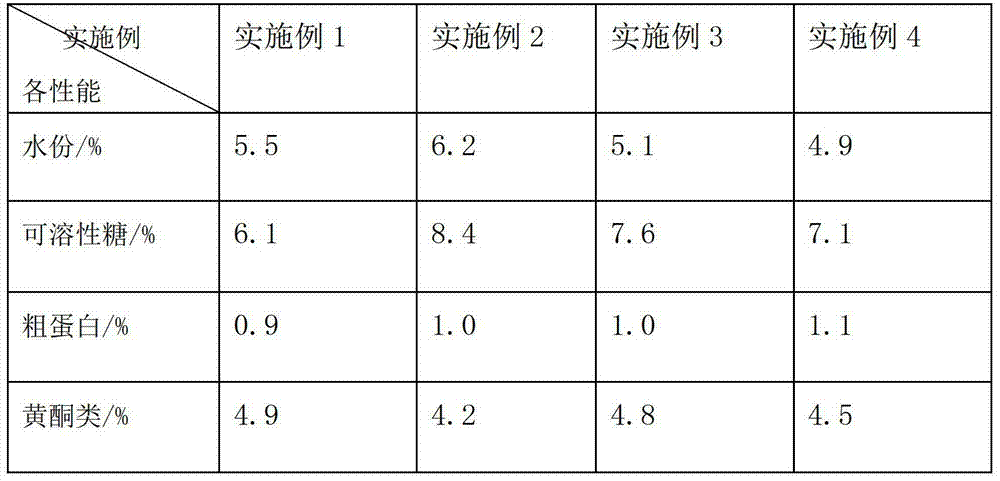

Examples

Embodiment 1

[0017] A kind of processing technology of mulberry leaf composite bag tea, its step comprises as follows:

[0018] (1) Raw materials: picking mulberry leaves from September to December, ganoderma lucidum, wolfberry, jasmine tea;

[0019] (2) Processing of mulberry leaves: a, spreading: spread the picked mulberry leaves for 70-80 minutes, and the thickness of spreading leaves is 2-3 cm; b, microwave finishing: spread the mulberry leaves in a microwave machine, The thickness is 2 to 3 cm, and it is greened at 120 to 130 ° C for 2 to 3 minutes; c, kneading: put the mulberry leaves after greening into a kneading machine at 55 to 60 rpm, and knead for 10 to 12 minutes; d, Baking: Put the twisted mulberry leaves into a hot air dryer, and dry them for 4-6 hours at a temperature of 80-90°C, and finish baking when the water content in the mulberry leaves is below 5%; Sieve the ash to get the mulberry leaf tea powder;

[0020] (3) Processing of Ganoderma lucidum, Lycium barbarum and J...

Embodiment 2

[0025] A kind of processing technology of mulberry leaf composite bag tea, its step comprises as follows:

[0026] (1) Raw materials: picking mulberry leaves from September to December, ganoderma lucidum, wolfberry, jasmine tea;

[0027] (2) Processing of mulberry leaves: a, spreading: spread the picked mulberry leaves for 70-80 minutes, and the thickness of spreading leaves is 2-3 cm; b, microwave finishing: spread the mulberry leaves in a microwave machine, The thickness is 2 to 3 cm, and it is greened at 120 to 130 ° C for 2 to 3 minutes; c, kneading: put the mulberry leaves after greening into a kneading machine at 55 to 60 rpm, and knead for 10 to 12 minutes; d, Baking: Put the twisted mulberry leaves into a hot air dryer, and dry them for 4-6 hours at a temperature of 80-90°C, and finish baking when the water content in the mulberry leaves is below 5%; Sieve the ash to get the mulberry leaf tea powder;

[0028] (3) Processing of Ganoderma lucidum, Lycium barbarum and J...

Embodiment 3

[0033] A kind of processing technology of mulberry leaf composite bag tea, its step comprises as follows:

[0034] (1) Raw materials: picking mulberry leaves from September to December, ganoderma lucidum, wolfberry, jasmine tea;

[0035] (2) Processing of mulberry leaves: a, spreading: spread the picked mulberry leaves for 70-80 minutes, and the thickness of spreading leaves is 2-3 cm; b, microwave finishing: spread the mulberry leaves in a microwave machine, The thickness is 2 to 3 cm, and it is greened at 120 to 130 ° C for 2 to 3 minutes; c, kneading: put the mulberry leaves after greening into a kneading machine at 55 to 60 rpm, and knead for 10 to 12 minutes; d, Baking: Put the twisted mulberry leaves into a hot air dryer, and dry them for 4-6 hours at a temperature of 80-90°C, and finish baking when the water content in the mulberry leaves is below 5%; Sieve the ash to get the mulberry leaf tea powder;

[0036] (3) Processing of Ganoderma lucidum, Lycium barbarum and J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com