Cascaded PID based charging moisture control device in tobacco shred processing technology

A control device and cascading technology, applied in tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of poor moisture control ability, untimely human intervention, low moisture completion rate, etc., to eliminate hysteresis and reduce human intervention. The effect of timely and stable fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

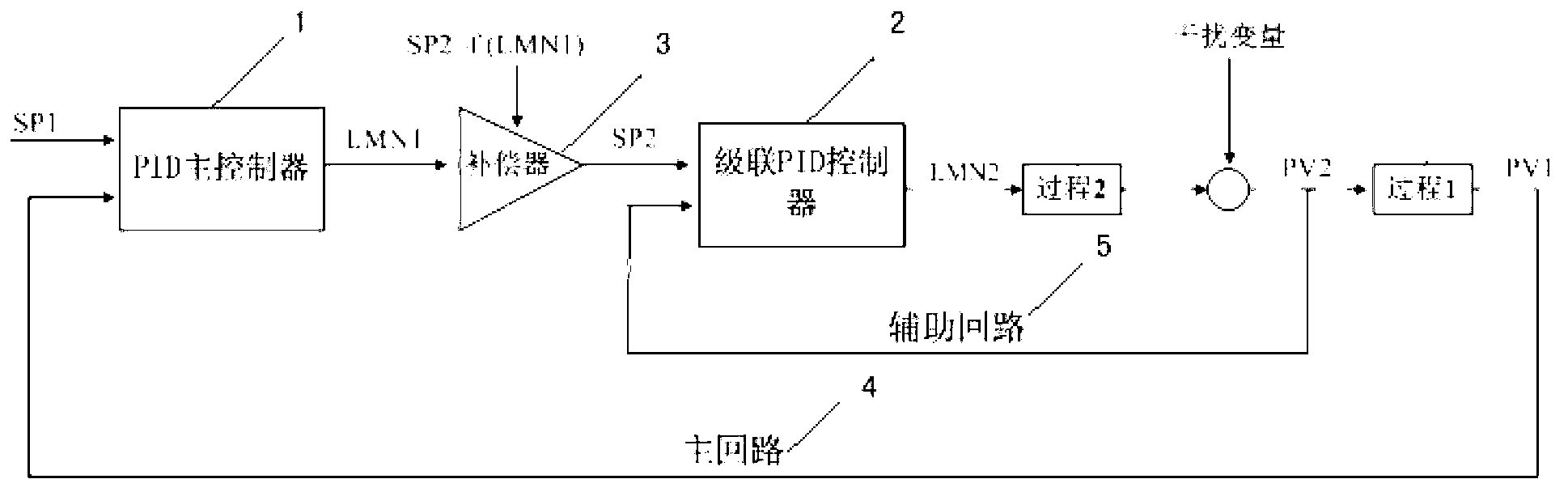

[0013] Such as figure 1 Shown is a cascaded PID-based feeding moisture control device in the tobacco shredded process, which includes a PID main controller 1, a cascaded PID controller 2, a linear compensator 3, a main loop 4, an auxiliary loop 5, Steam meter and moisture meter. The two PIDs of the PID master controller 1 and the cascade PID controller 2 are connected in series, and the linear compensator 3 is connected in series between the PID master controller 1 and the cascade PID controller 2, and the The main loop 4 feeds back the outlet moisture PV1 to the input end of the PID main controller 1, and the auxiliary loop 5 feeds back the current cylinder wall temperature PV2 to the input end of the cascaded PID controller 2. The PID master controller 1 determines the set point of the cascaded PID controller 2, and the PID m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com