Structural component for fixing auscultator head and fixing part

A technology of matching structures and fixing parts, applied in stethoscopes and other directions, can solve problems such as inability to ensure consistent assembly, troubles, and affecting listening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

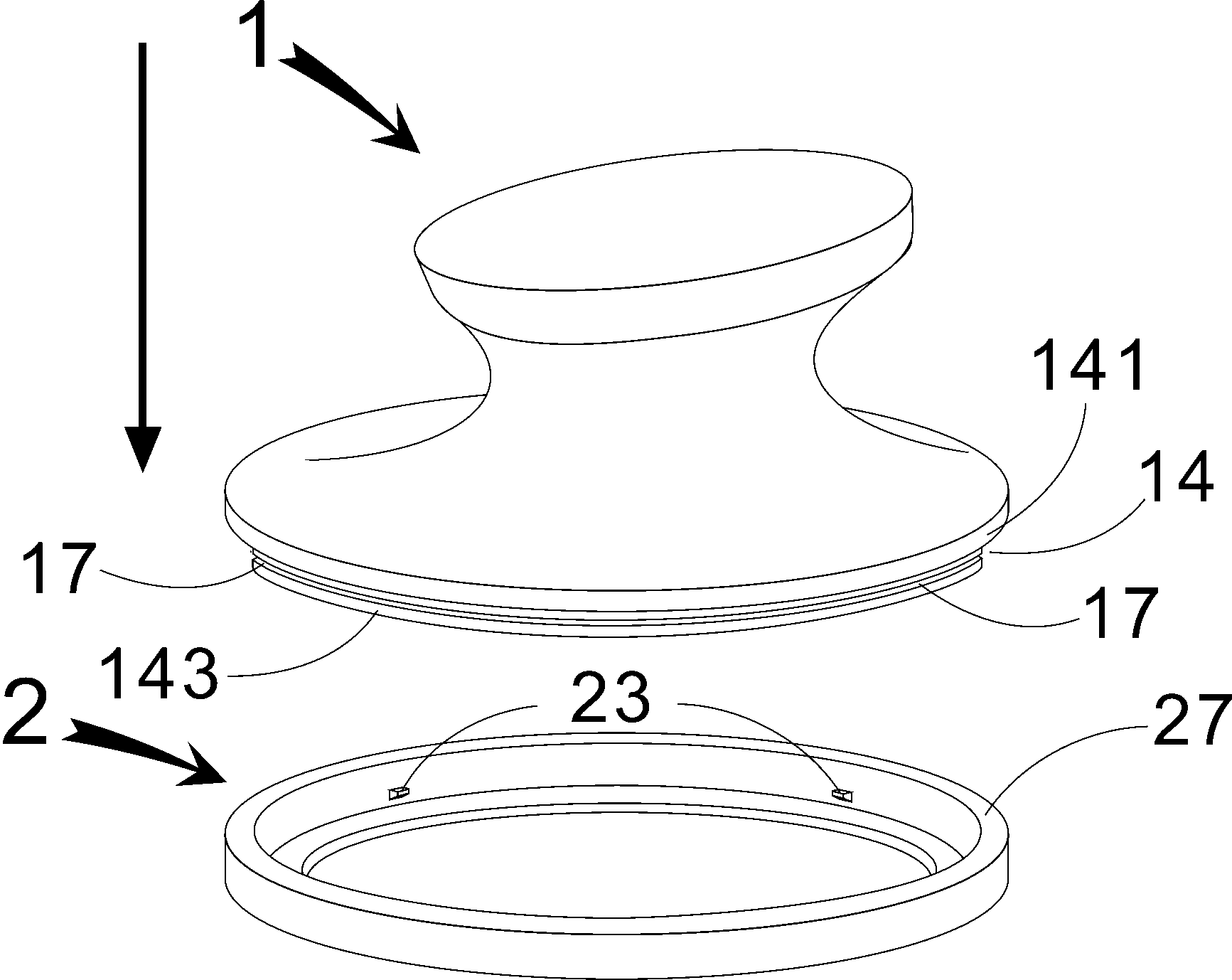

[0046] The matching structural assembly of the listening head body and the fixing part, including the listening head body 1 and the fixing part 2, the listening head body is provided with a rotating shaft hole 11, a sound guide hole 12 and a sound collecting surface 13 which are connected to each other, and the fixing part 2 is arranged along the axis. There are through holes 21 and half through holes 22 with coincident axes and different apertures. The half through hole aperture 221 is greater than the through hole aperture 211. An annular step 14 is provided on the listening head body 1 on the side of the sound collecting surface 13. The annular step 14 includes an annular first side 141, a first bottom 142 and an annular second side 143, the first side 141 and the second side 143 are connected by the first bottom 142; Ring-shaped step 14 cooperates and fixes.

[0047] Further, the outer diameter 15 of the earpiece body of the first side 141 is larger than the diameter 221 o...

Embodiment 2

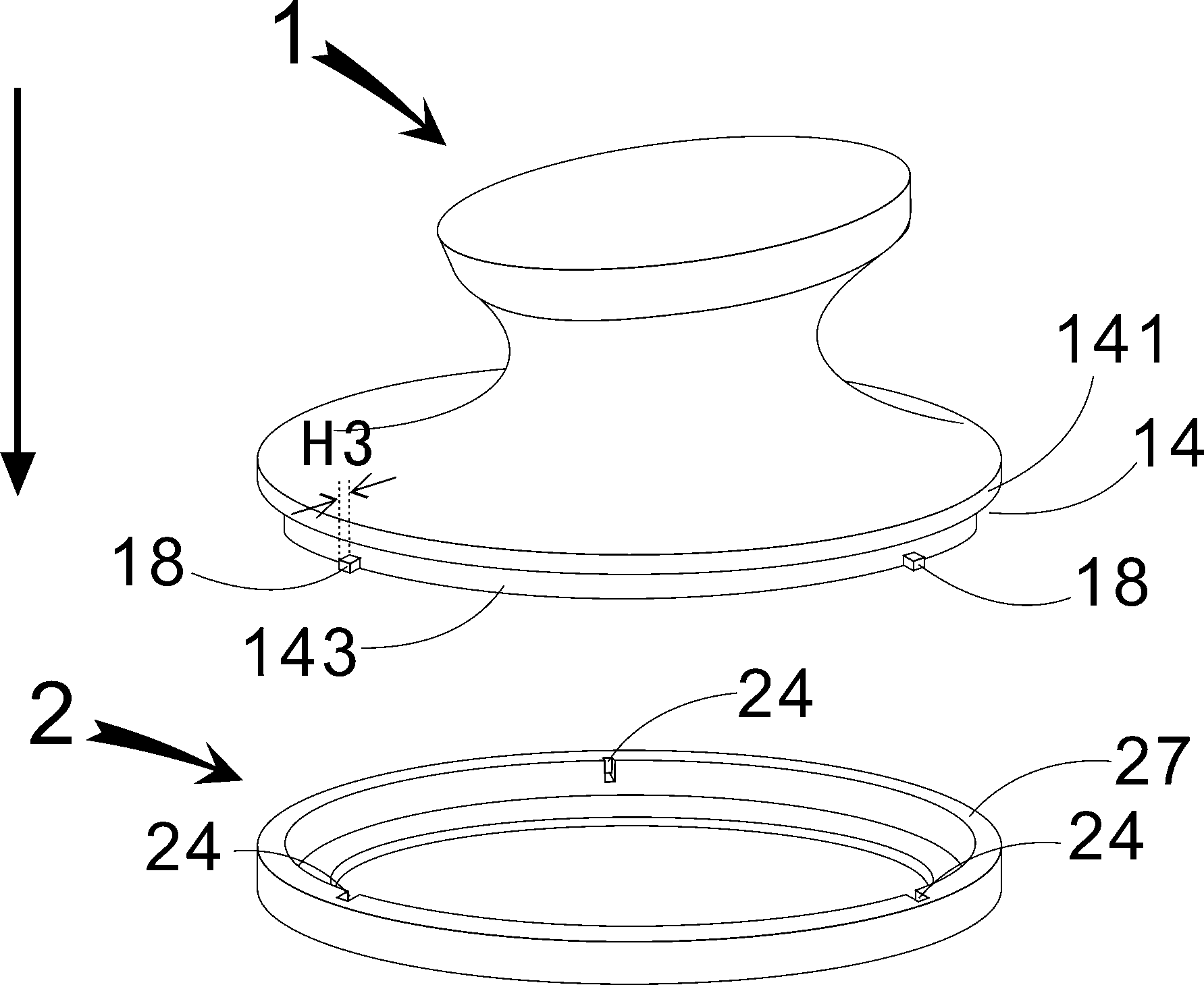

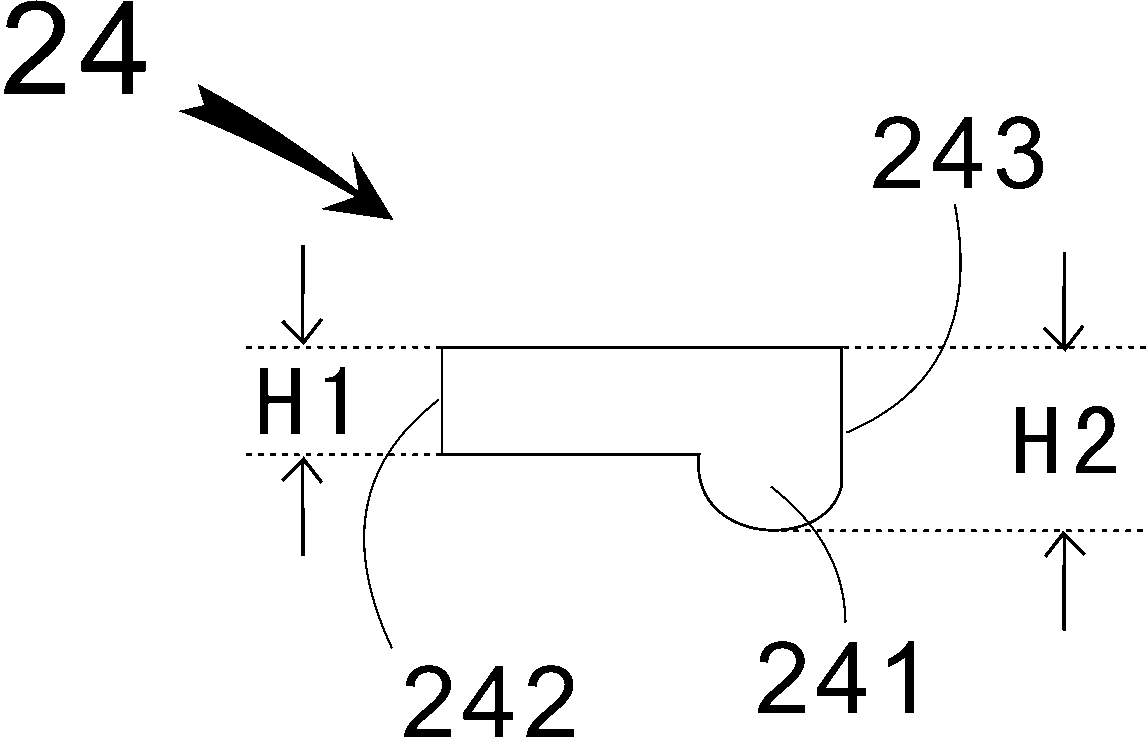

[0059] Example 2: Combining Figure 7 , Figure 10 It can be seen that

[0060] When the fixing part 2 and the ring-shaped step 14 are turned buckles,

[0061] The matching structural assembly of the listening head body and the fixing part, including the listening head body 1 and the fixing part 2, the listening head body is provided with a rotating shaft hole 11, a sound guide hole 12 and a sound collecting surface 13 which are connected to each other, and the fixing part 2 is arranged along the axis. There are through holes 21 and half through holes 22 with coincident axes and different apertures. The half through hole aperture 221 is greater than the through hole aperture 211. An annular step 14 is provided on the listening head body 1 on the side of the sound collecting surface 13. The annular step 14 includes an annular first side 141, a first bottom 142 and an annular second side 143, the first side 141 and the second side 143 are connected by the first bottom 142; Ri...

Embodiment 3

[0068] Example 3: Binding Figure 9 , Figure 10 It can be seen that:

[0069] The matching structural assembly of the listening head body and the fixing part, including the listening head body 1 and the fixing part 2, the listening head body is provided with a rotating shaft hole 11, a sound guide hole 12 and a sound collecting surface 13 which are connected to each other, and the fixing part 2 is arranged along the axis. There are through holes 21 and half through holes 22 with coincident axes and different apertures. The half through hole aperture 221 is greater than the through hole aperture 211. An annular step 14 is provided on the listening head body 1 on the side of the sound collecting surface 13. The annular step 14 includes an annular first side 141, a first bottom 142 and an annular second side 143, the first side 141 and the second side 143 are connected by the first bottom 142; Ring-shaped step 14 cooperates and fixes.

[0070] The internal thread 26 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com