100kW low-noise emergency diesel-oil electric generator wagon

A technology for diesel generator sets and generator cars, which is applied to motor vehicles, goods transport vehicles, vehicles used for freight, etc., and can solve the problems of no fixed protection device for cables, no sound insulation and noise reduction measures, and time-consuming and labor-intensive manual winding. , to achieve the effect of beautiful appearance, long service life and reducing sound leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

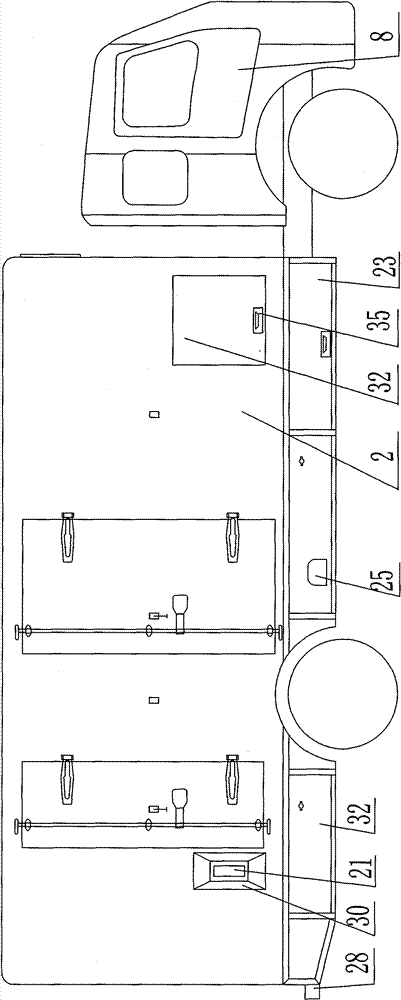

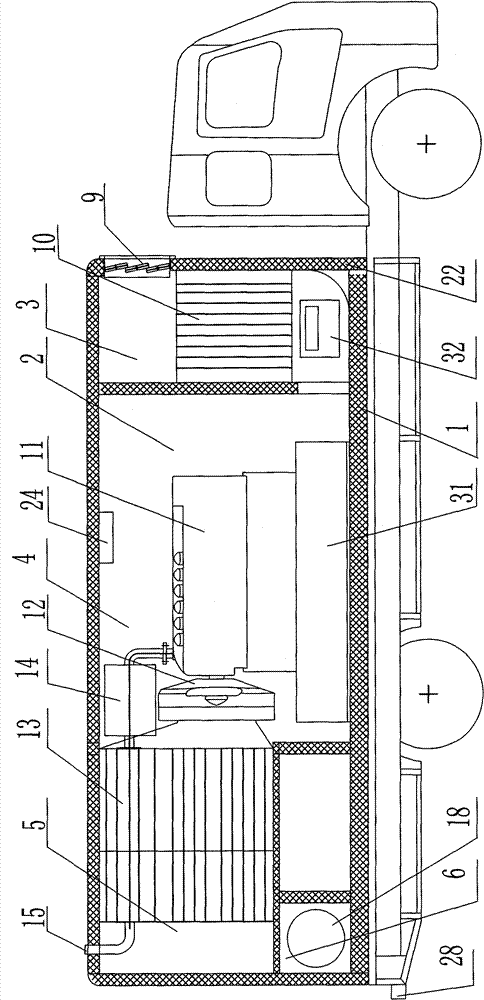

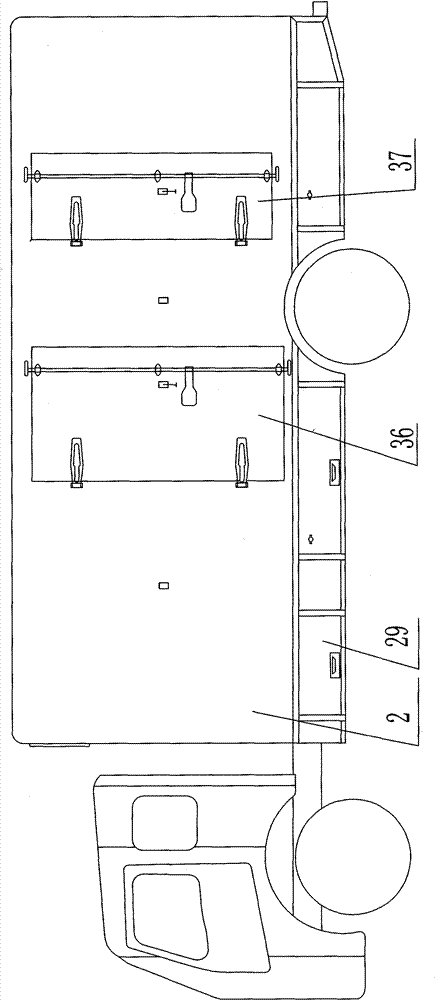

[0032] A 100kW low-noise emergency diesel generator car, which consists of: a truck chassis 1 with a 100kW diesel generator set and an electrical control device, a sound insulation box 2 is installed on the truck chassis 1, and the In the sound box body 2, the air inlet cabin 3, the main engine cabin 4, the air exhaust cabin 5, the roller cabin 6, and the control cabin 7 are installed in sequence, and the described truck chassis 1 is connected with the front 8.

[0033] In the 100kW low-noise diesel generator car, the air intake compartment 3 includes an electric air intake louver 9, and the electric air intake louver 9 is connected to the air intake muffler 10; the main cabin 4 includes a diesel generator set 11, The outlet of the diesel generator set 11 is connected to the canvas soft connection 12; the exhaust cabin 5 includes a box exhaust muffler 13 and a smoke exhaust muffler 14, and the smoke exhaust muffler 14 is connected to the sound insulation box The smoke outl...

Embodiment 2

[0039] An implementation method of a 100kW low-noise emergency diesel generator car. The implementation process of the generator car should be three parts: the start-up process, the power generation process and the shutdown process of the diesel generator set. During the start-up process, the exhaust door should be closed before the unit starts. Open the electric air intake louvers and connect the power transmission cable at the same time; in the process of power generation, the power generation power should be determined first, the reason is that the power generation car has two sets of power transmission circuits, and each set of power transmission circuits has its own maximum output power value; During the shutdown process, the standby unit should stop working completely, and the transmission line should be completely disconnected and put away, and then close the electric air intake louvers and exhaust doors on the box.

Embodiment 3

[0041] For the 100kW low-noise emergency diesel generator car described in Embodiment 1 or 2, the sound insulation box adopts an integral box-packed structure. The structural frame of the sound insulation box is welded with profiles. Corresponding to the load-bearing positions of diesel engines and generators, the underframe structure correspondingly adds necessary load-bearing beams to enhance the load-bearing capacity of the underframe to ensure that low-noise emergency diesel generator vehicles can operate on the highway. The structure is stable and the operation is safe when driving on the road.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com