Novel transverse blowing pipe of traveling cleaner

A cleaner and horizontal blowing technology, which is applied in the direction of textiles and papermaking, etc., can solve the problems of reducing the quality of dust removal, the inability to adjust the air volume, and affecting the effect of blowing, so as to improve the quality of dust removal and ensure the effect of blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

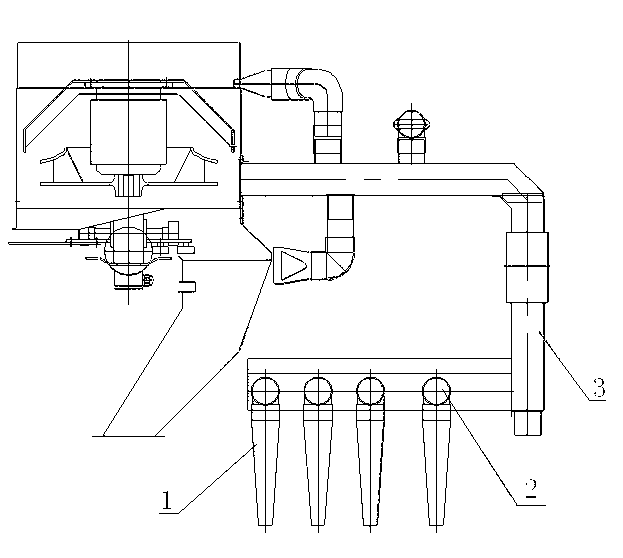

[0010] see figure 1 , the present invention relates to a novel horizontal blowpipe of a itinerant cleaner, comprising a horizontal blowpipe 1, said horizontal blowpipe 1 has several, said several horizontal blowpipes 1 are arranged side by side, wherein the rear end of each horizontal blowpipe 1 is connected to the blower The rear section of the pipe 3 is hinged, so that the horizontal blowpipe 1 can rotate 360°. The front opening of the horizontal blowpipe 1 is a blower port, which can perform dust removal in all directions, wherein an adjustment plate 2 is installed inside the rear end of each horizontal blowpipe 1 , the adjusting plate 2 can adjust the air volume of each horizontal blowing pipe 1, which ensures the blowing effect and improves the dust removal quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com