A Method for Controlling Bottom Rise of Dephosphorization Furnace

A furnace bottom rise and dephosphorization furnace technology, applied in the direction of manufacturing converters, etc., can solve problems such as affecting the bottom blowing effect and furnace bottom rising.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

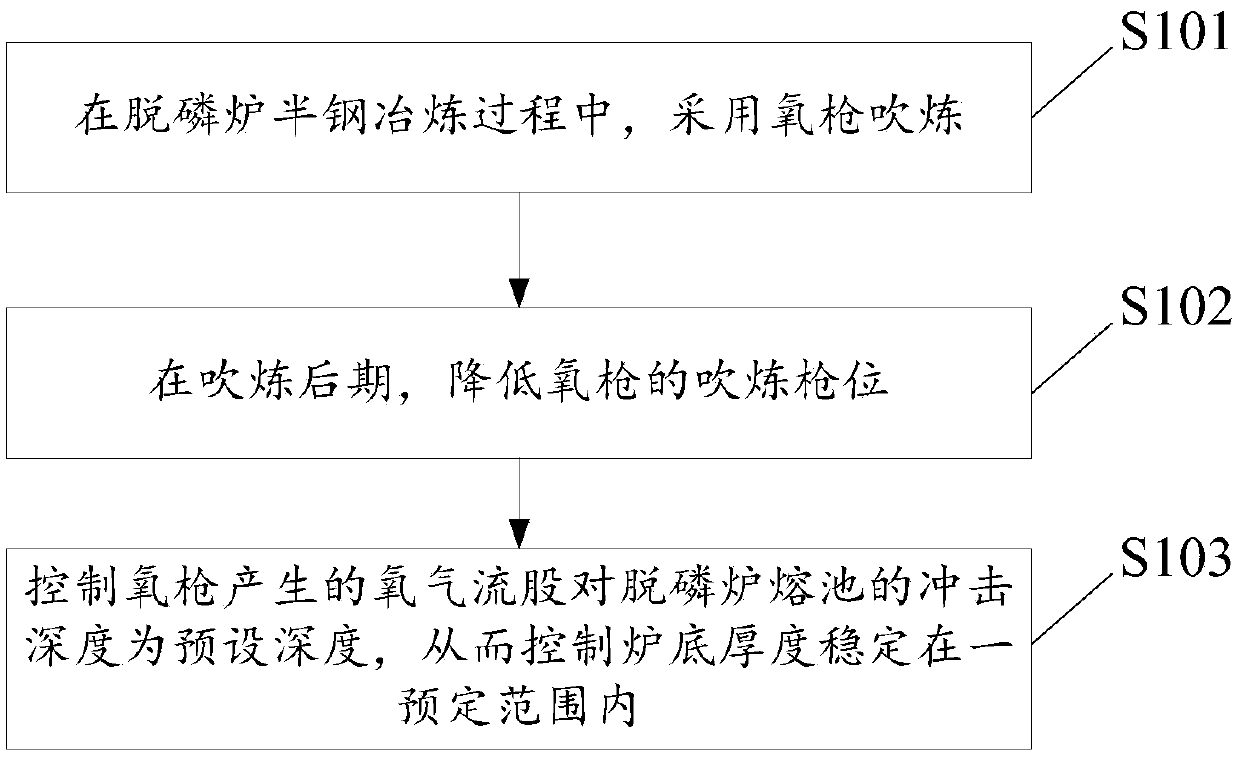

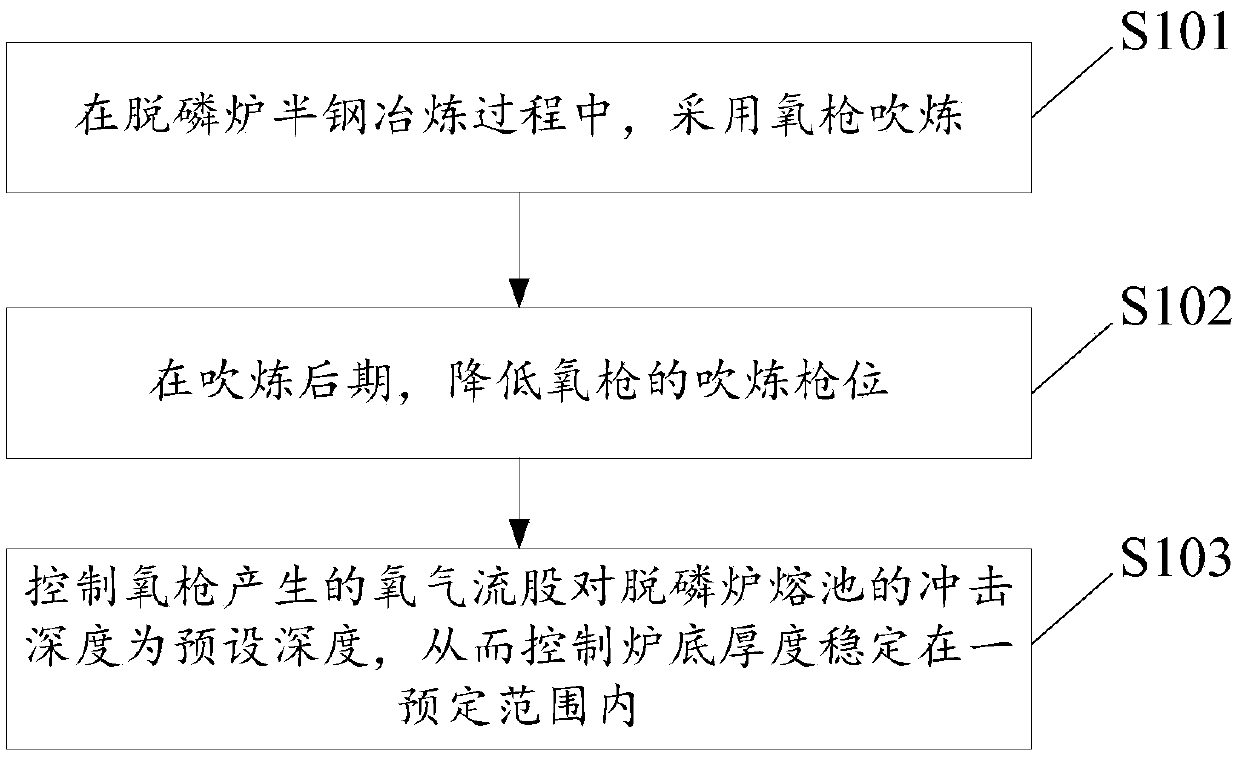

[0026] This embodiment provides a method for controlling the rising of the bottom of the dephosphorization furnace, such as figure 1 shown, including:

[0027] Step S101: During the smelting process of semi-steel in the dephosphorization furnace, oxygen lance blowing is used.

[0028] Step S102: In the later stage of blowing, lower the blowing lance position of the oxygen lance.

[0029] Step S103: controlling the impact depth of the oxygen stream generated by the oxygen lance on the molten pool of the dephosphorization furnace to a preset depth, so as to control the thickness of the furnace bottom to be stable within a predetermined range.

[0030] As an optional implementation, the oxygen lance is a four-hole oxygen lance.

[0031] As an optional implementation, the nozzle parameters of the oxygen lance are: center inclination angle 13°-14°, Mach number 2.10-2.20.

[0032] For example, the central inclination angle can be: 13.0°, or 13.1°, or 13.2°, or 13.3°, or 13.4°, or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mach number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com