Sewing machine with pucker preventing effect

A sewing machine and machine head technology, which is applied to sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of not being able to ensure fabric tension, smooth and smooth surface, affecting sewing quality, etc., and achieve great application and promotion value. Beautiful, avoid deformation and wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

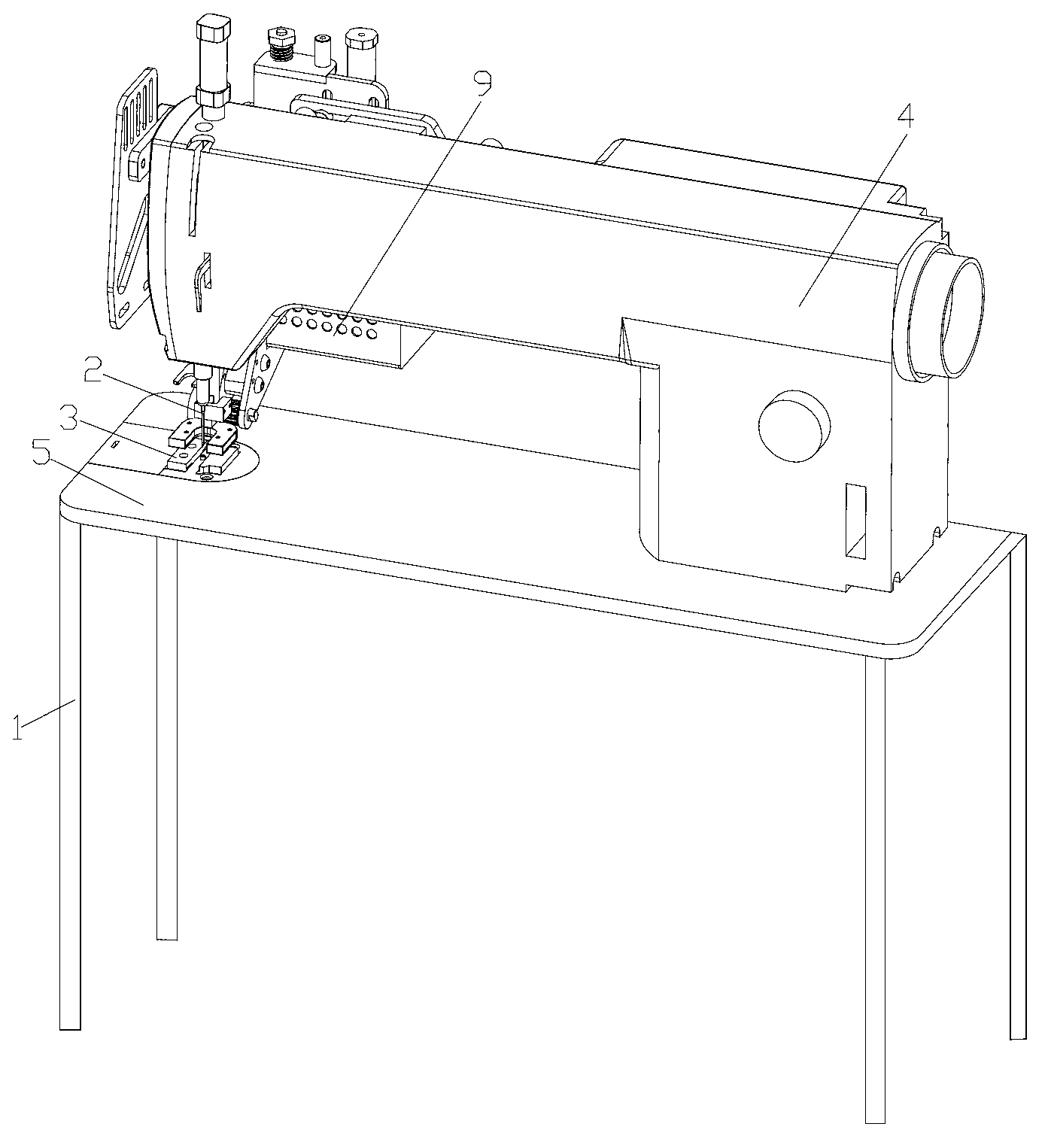

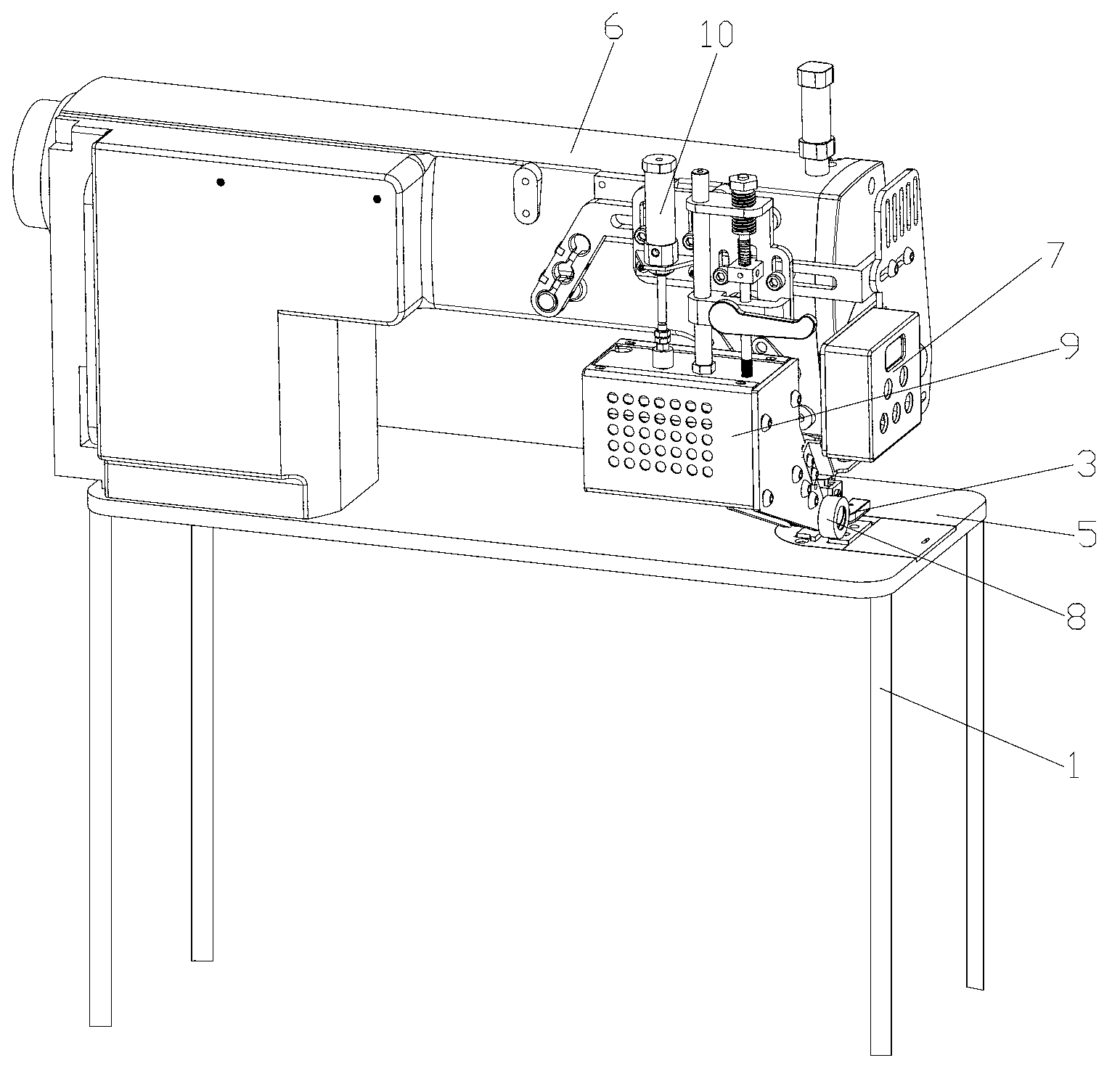

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached Figure 1-2 The shown anti-wrinkle sewing machine of the present invention comprises a frame 1, a fixed plate 5, 4 sewing machine heads including a plurality of parts including a sewing needle 2 and a needle plate 3, and a machine head for sewing Transmission mechanism (not shown in the figure), driving mechanism, operation panel 7 and synchronous wheel 8; The frame 1 is fixedly connected with the fixed plate 5; The sewing machine head 4 is located on the fixed plate 5; The driving mechanism is connected with the fixed plate 5 The operation panel 7 is connected; the drive mechanism and the operation panel 7 are respectively fixedly arranged on the sewing machine head 5; a synchronous wheel 8 is arranged below the drive mechanism; the synchronous wheel 8 is lifted and rotated by the drive mechanism and the operation panel 7 The power device of the drive mechanism incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com