Rotation-free locking ring type sliding sleeve with ball seat capable of being taken out

A ball seat and ring type technology, applied in the field of non-rotation locking ring type removable ball seat sliding sleeve, can solve the problems of tool jamming, fishing action ground cannot be accurately judged, etc., and achieve easy unlocking, low salvage cost, and reliable locking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

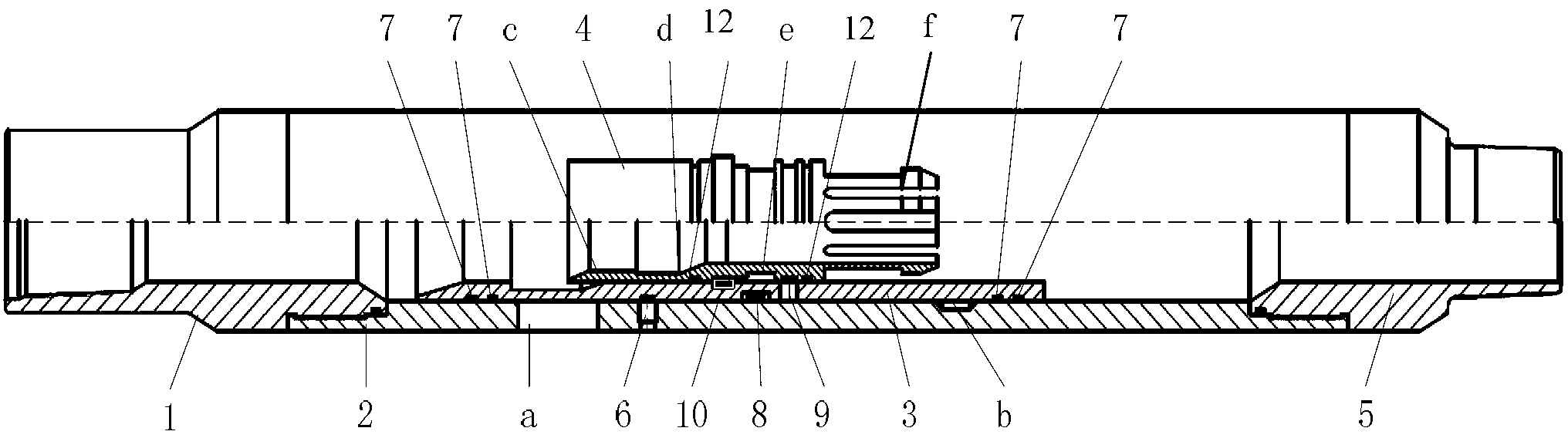

[0029] The implementation method of the free-rotation locking ring type removable ball seat sliding sleeve of the present invention is as follows:

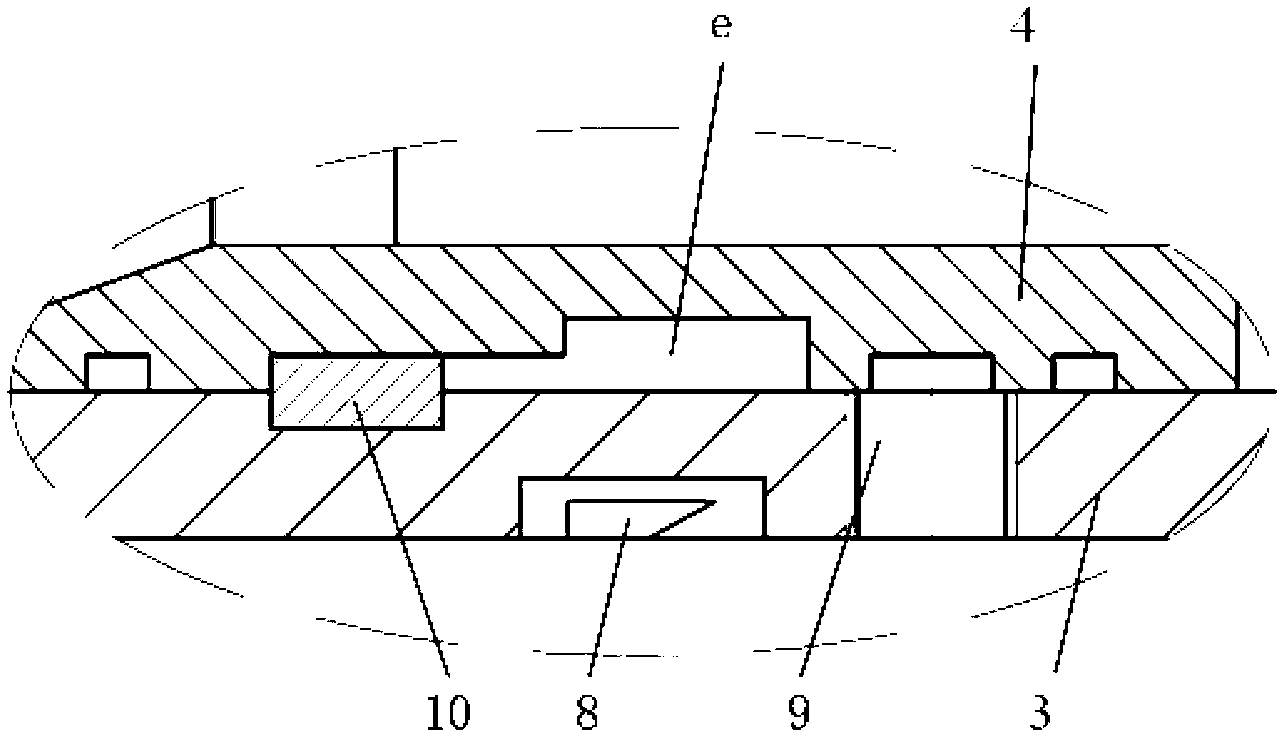

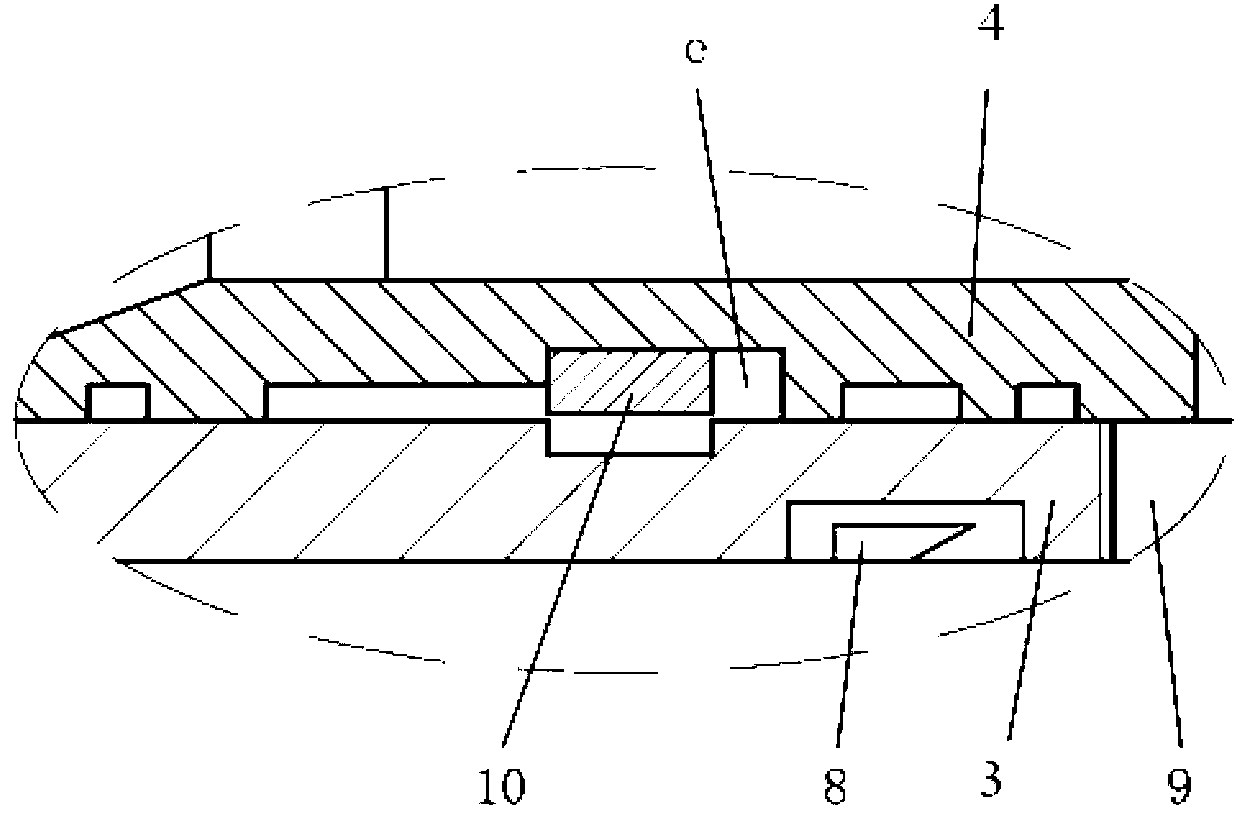

[0030] Firstly, lower the sliding sleeves of all levels into the designated positions, put in the ball with the smallest diameter, and the ball falls into the variable-diameter ball seat e with the smallest inner diameter at the bottom of the wellbore, and press down to make the ball seat generate a downward force, driving the inner sliding sleeve 3 to face each other. The outer cylinder 2 moves down, the shear pin 6 is cut off to open the sliding sleeve, and when the snap ring 8 moves down to the position of the lock ring groove b, it snaps into the lock ring groove b, thereby limiting the further downward movement of the inner sliding sleeve 3 . In this way, open all the sliding sleeves from bottom to top in turn. Then, drop in Figure 4 For the fishing tool shown, the male pawl g of the fishing tool is inserted into the female...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com