Cleaning device capable of automatically switching between water and air

A technology for automatic switching and cleaning of devices, applied in valve devices, injection devices, engine components, etc., to shorten the injection time, facilitate maintenance and care, and simplify the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings:

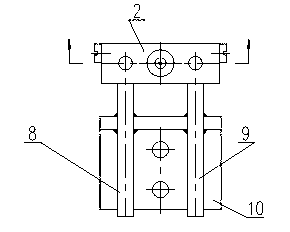

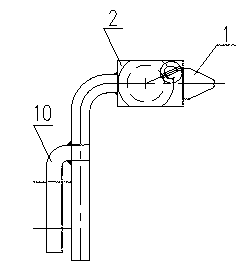

[0019] figure 1 It is a front view of the present invention. The water nozzle 8 and the air nozzle 9 are welded on the bracket 10 , and the upper ends are welded on both sides of the valve seat 2 .

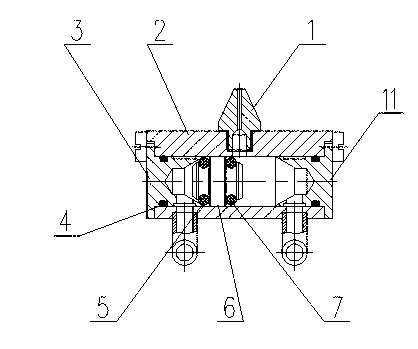

[0020] figure 2 It is a sectional view of the valve seat part of the present invention. The valve seat 2 is equipped with a nozzle 1, the two ends of the valve seat 2 are installed with a left head 3 and a right head 11, the sealing heads at both ends and the valve seat 2 are sealed with a sealing ring 4, and the valve seat 2 has a valve hole inside the valve hole. A valve core 6 is installed inside, and the outer edges of the two sides of the valve core are respectively covered with a first sealing ring 5 and a second sealing ring 7. The valve core slides in the valve hole under the influence of water pressure or air pressure to realize automatic water and gas switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com