An ultra-low frequency and high-precision micro-vibration measurement system

A measurement system and high-precision technology, applied in vibration testing, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of not meeting the vibration test requirements of the solar wing drive mechanism and the low accuracy of piezoelectric force sensors. Achieve the effect of improving measurement accuracy, improving adaptability, and overcoming low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

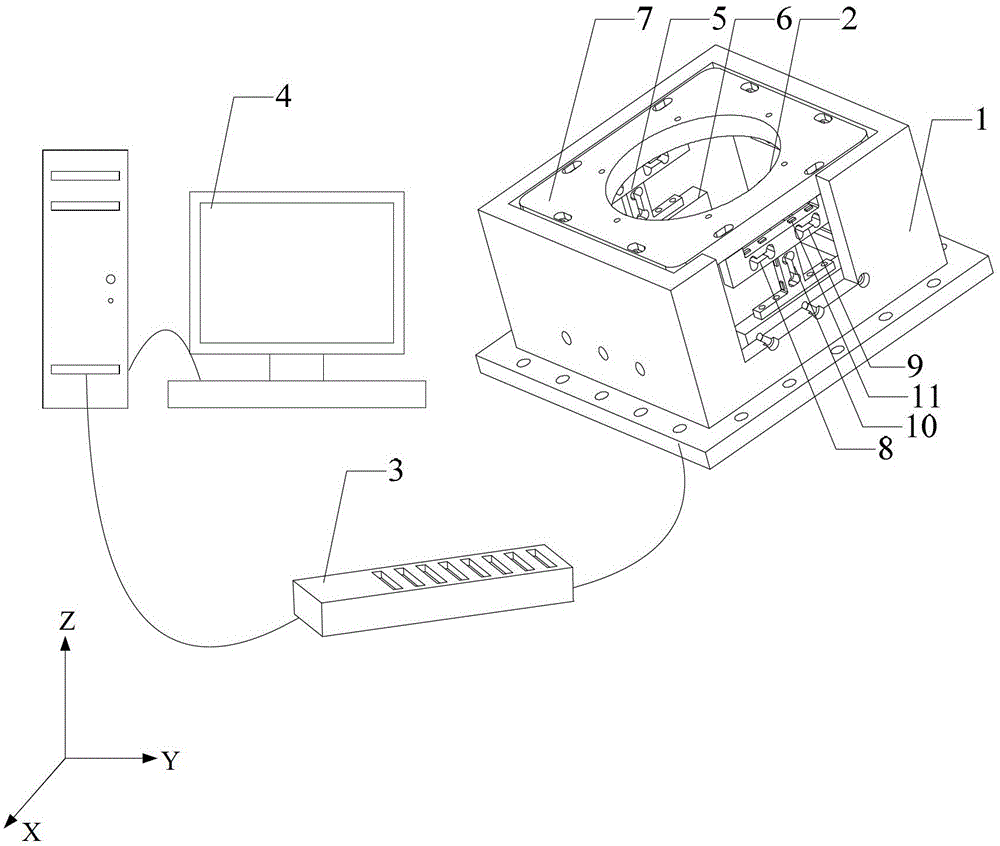

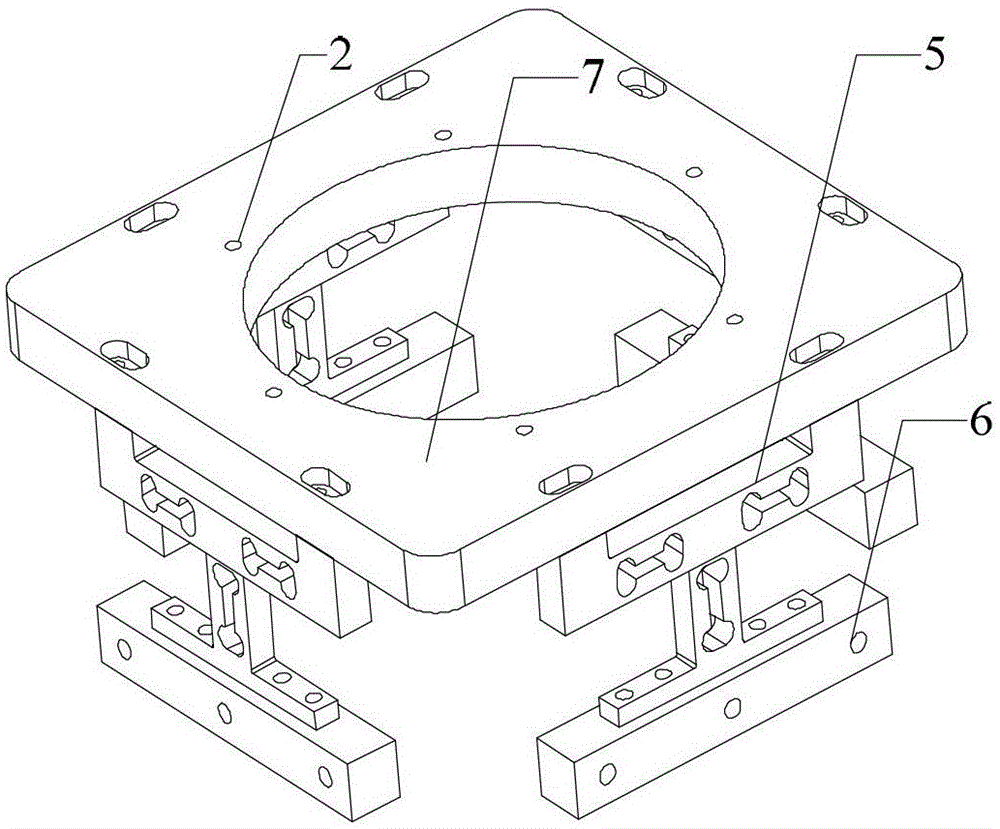

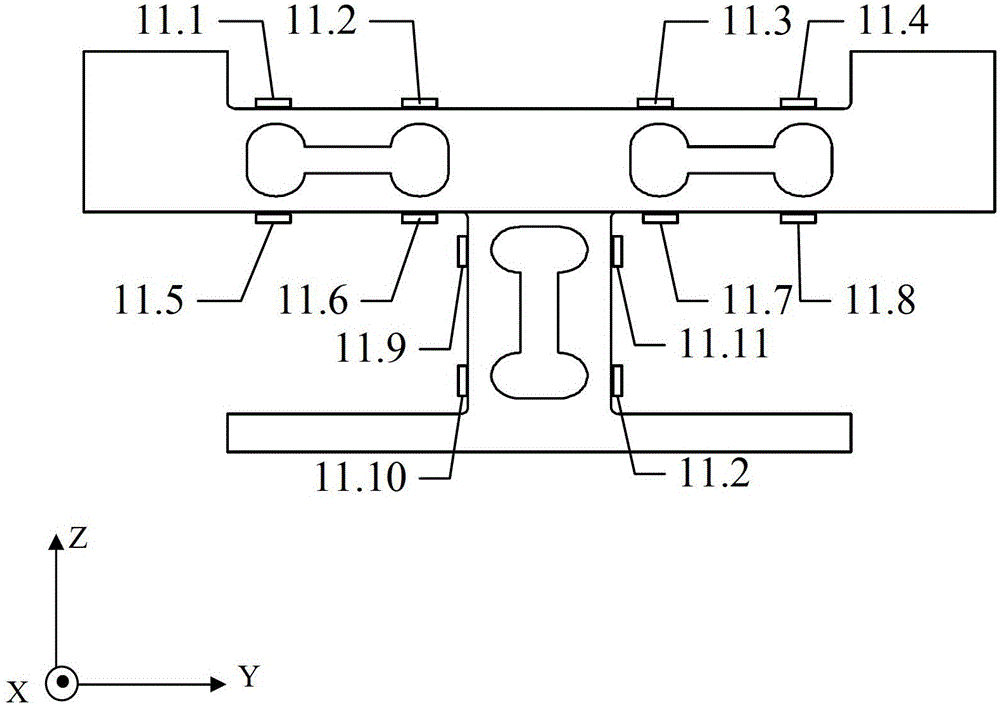

[0024] like figure 1 , figure 2 and image 3 As shown, an ultra-low frequency high-precision micro-vibration measurement system includes: a base 1, a force measuring device 2, a dynamic strain gauge 3, and a data acquisition and processing system 4; the force measuring device 2 consists of four strain gauge force sensors 5, four The adapter block 6 and the load plate 7 are composed; the four adapter blocks 6 are respectively located on the four side surfaces of the base 1, and each adapter block 6 is tightened on the side surface of the base 1 by three bolts; the four strain The strain gauge force sensor 5 is located between the upper surface of the four adapter blocks 6 and the lower surface of the load plate 7, and each strain gauge force sensor 5 is respectively tightened on the upper surface of the adapter block 6 and the lower surface of the load plate 7 by four bolts. Surface; the four strain gauge force sensors 5 are composed of three parts with the same shape, two o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com