High-responsivity organic sun-blind ultraviolet light detector

A responsivity, solar blind technology, applied in the field of detectors, can solve the problems of narrowing the selection space of organic materials and increasing the difficulty of device design, achieving the effect of low price and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

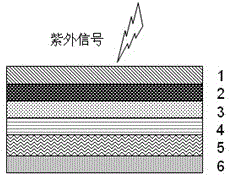

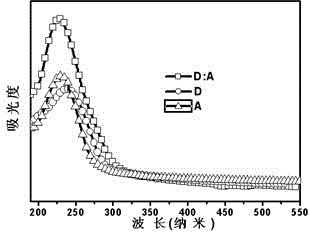

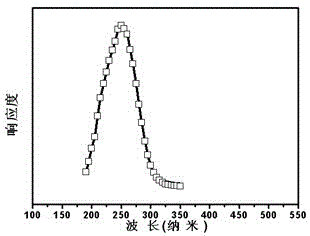

Embodiment 1

[0032] The glass substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, rinsed with deionized water, and dried. Vacuum-deposit a layer of 10nm-thick metal aluminum on the glass substrate, and then prepare a PEDOT:PSS (polyaniline derivative) hole transport layer with a thickness of about 40nm by spin coating after UV-ozone treatment, 120° Bake at C for 15 minutes and remove. Choose D (R is pyrazine) as the donor material, and A (R is triazole) as the acceptor material. First prepare D with a thickness of about 30nm on PEDOT:PSS by spin coating, and then prepare A with a thickness of about 20nm on the D film by vacuum evaporation. The above two layers constitute the organic activity of the planar heterojunction structure Floor. Finally, 1nm thick LiF and 100nm thick aluminum electrodes were sequentially prepared by vacuum evaporation. As mentioned above, get as figure 1 The high-responsivity organic sun-blind UV photodetector sh...

Embodiment 2

[0034] The quartz substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, rinsed with deionized water and dried. Vacuum-deposit a layer of metallic silver with a thickness of 20nm on the quartz substrate, after UV-ozone treatment, prepare a PEDOT:PSS (polyaniline derivative) hole transport layer with a thickness of about 40nm by spin coating, 120°C Remove from the oven after 15 minutes. Choose D (R is pyridine) as the donor material, and A (R is triazine) as the acceptor material. A mixed film with a thickness of about 70nm was prepared by vacuum mixed evaporation on PEDOT:PSS. During the preparation process, the weight ratio of donor material D:acceptor material A in the mixed film was 95:5 by controlling the evaporation rate. , forming an organic active layer with a bulk heterojunction structure. Finally, 1nm thick LiF and 200nm silver electrodes were sequentially prepared by vacuum evaporation method. As mentioned above, get a...

Embodiment 3

[0036] The quartz substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, rinsed with deionized water and dried. Vacuum-deposit a layer of 15nm thick metal gold on the quartz substrate, after UV-ozone treatment, prepare a PEDOT:PSS (polyaniline derivative) hole transport layer with a thickness of about 40nm by spin coating, 120°C Remove from the oven after 15 minutes. Choose D (R is pyridine) as the donor material, and A (R is pyridine) as the acceptor material. First prepare D with a thickness of about 30nm on PEDOT:PSS by vacuum evaporation, and then prepare A with a thickness of about 30nm on the D film by vacuum evaporation. active layer. Finally, 1nm thick LiF and 300nm gold electrodes were sequentially prepared by vacuum evaporation. As mentioned above, get as figure 1 A high-responsivity solar-blind UV detector is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com