Self-calibration electric coupler with buffer device

An electrical connector and buffer device technology, applied in the field of self-calibrating electrical connectors, can solve problems such as excessive extrusion, troublesome automatic docking of two devices, and electrical connector position deviation, and achieve the effect of precise connection and safe and reliable electrical connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

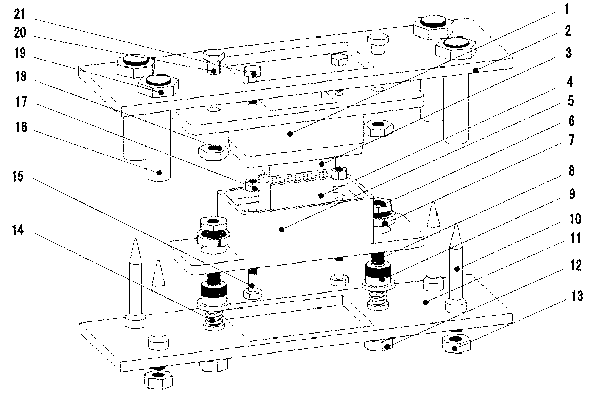

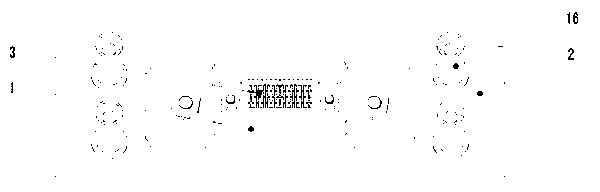

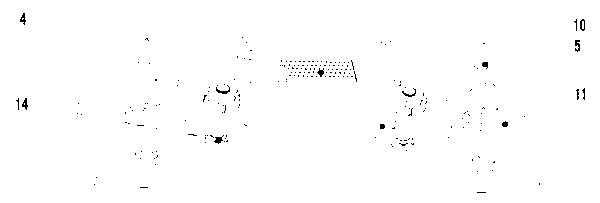

[0027] Please refer to Figure 1 to Figure 6 As shown, the self-calibrating electrical connector with a buffer device of the present invention includes a plug assembly and a socket assembly, wherein the plug assembly includes a plug guide seat 1, a plug base 2, a plug electrical connector 3, a guide hole 16, and a plug seat Nut 18, guide hole nut 19, plug seat screw 20, plug fixing screw 21. Wherein the plug guide seat 1 is arranged on the plug base 2 with a smooth contact surface, and is connected by a plug seat nut 18 and a plug seat screw 20 . The plug electrical connector 3 is installed in the plug guide seat 1 and connected by plug fixing screws 21 . The plug guide seat 1 has the function of final precise positioning and can effectively protect the plug electrical connector 3 . There are four guide holes 16, which are distributed around the plug guide seat 1. The outermost of the guide holes 16 is a conical hole, which gradually transitions to a cylindrical hole. The pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com