Box-erecting device

A vertical box and fixing device technology, applied in the field of machinery, can solve the problems of gloves tearing, easily squeezed into the surrounding gaps, and affecting the qualified rate of boxing, so as to achieve reliable pick-and-place, flexible and convenient use, and ensure automation and continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

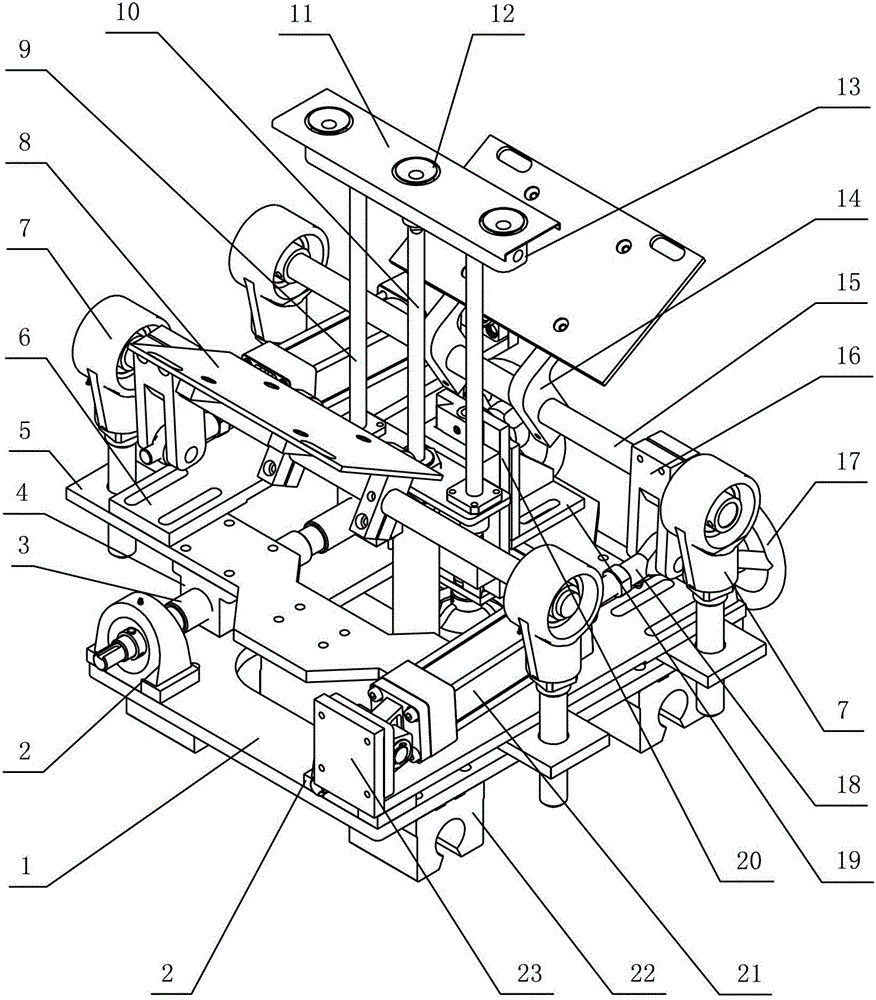

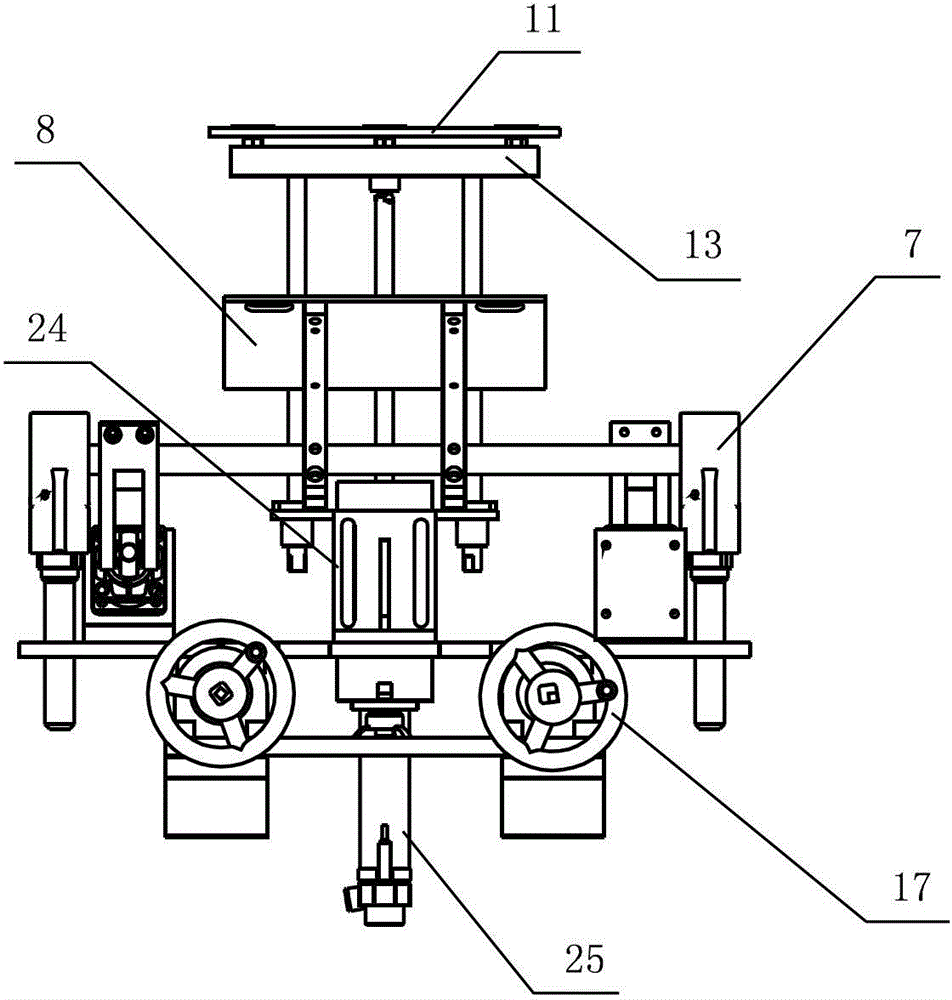

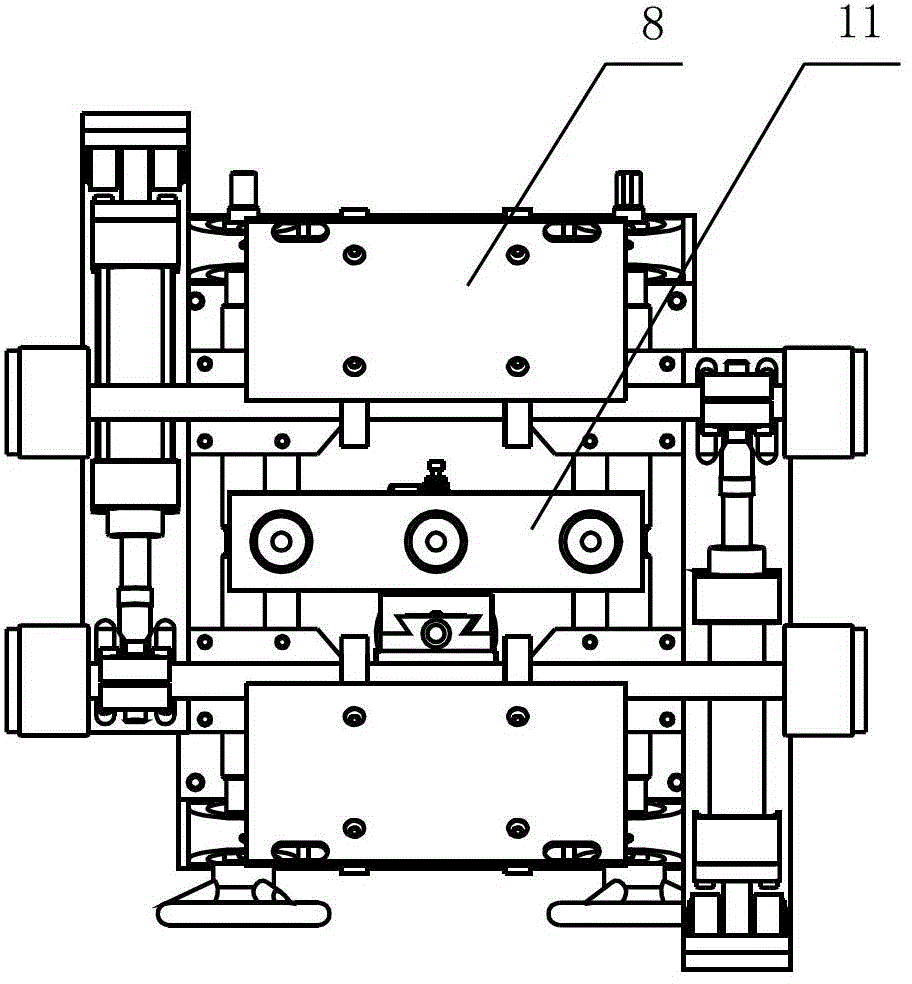

[0031] Such as Figure 1~6 As shown, the present embodiment includes a mounting seat 16, a mounting plate 5, and a carton board supporting plate 11. A slider 22 is arranged at the bottom of the mounting seat 16, and the mounting plates 5 are respectively arranged on both sides of the mounting seat 16, and the mounting plates 5 on both sides are connected by The plate 6 is connected, the mounting plate 5 is connected with the mounting seat 16 through the adjustment device; the carton plate fixing device is set on the carton plate supporting plate 11, and the carton plate fixing device includes a suction cup 12, and the upper part of the suction cup 12 is set on the carton plate supporting plate 11 Above, the upper surface of the suction cup 12 is slightly higher than the carton board pallet 11, the bottom of the suction cup 12 is fixed in the suction cup seat 13, the side end of the suction cup seat 13 is provided with a suction port to connect with the suction device, the sucti...

Embodiment 2

[0035] Such as figure 1 , Figure 7-8 As shown, the supporting plate cylinder seat 24 is fixed on the concave plate 26 of the dovetail groove, the concave plate 26 of the dovetail groove slides and cooperates with the convex plate 20 of the dovetail groove, the convex plate 20 of the dovetail groove is fixed on the mounting base 5 through the folding plate 19, and the concave plate of the dovetail groove The center of the plate 20 is provided with a central opening, and the screw rod 32 passes into the central opening. The bottom of the central opening is provided with a lower screw 33 to cooperate with the screw 32. The lower screw 33 is fixed on the convex plate 20 of the dovetail groove, and the top of the central opening is Set the upper threaded part 29 to cooperate with the screw rod 32, the upper threaded part 29 is fixed on the concave plate 26 of the dovetail groove, the end of the screw rod 32 is provided with a lifting hand wheel 28, and a stopper is set between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com