Processing fixture for producing garment piece hem

A garment piece and fixture technology, applied in textiles and papermaking, cloth feeding mechanism, sewing equipment, etc., can solve problems such as troublesome manual operation, unguaranteed product quality, and low work efficiency, so as to ensure product quality and meet production requirements. Requirements, easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

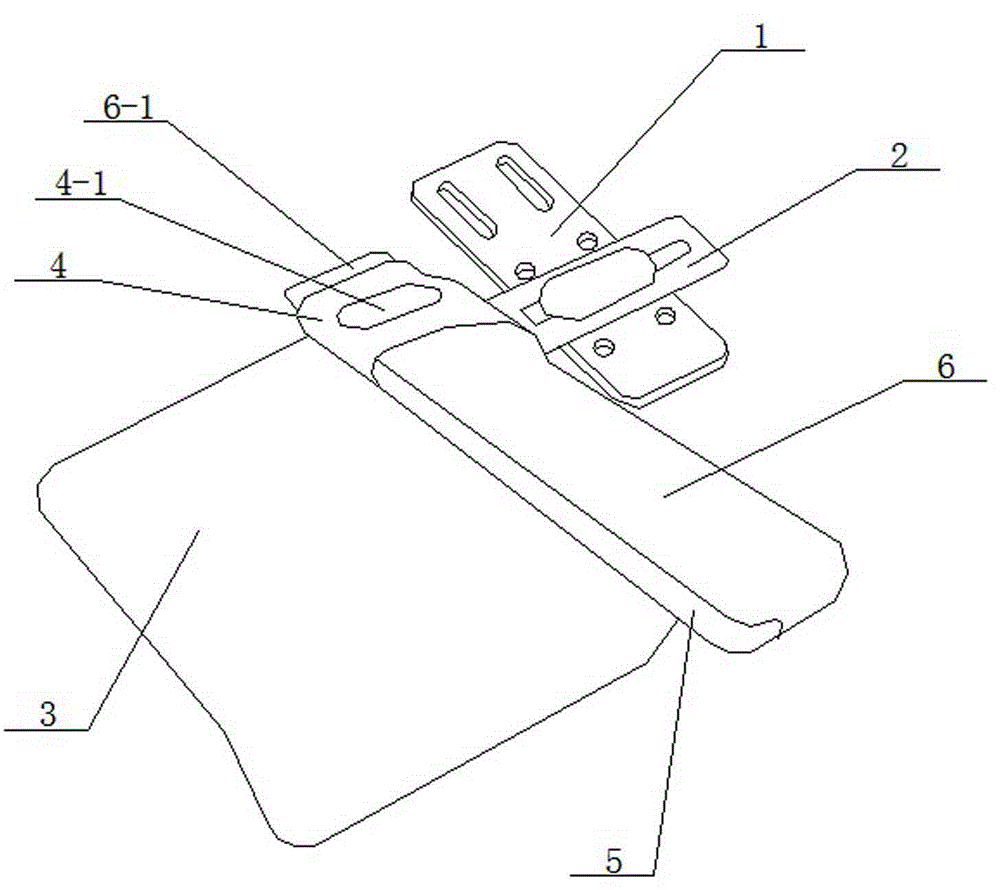

[0009] refer to figure 1 , the specific embodiment adopts the following technical solutions: a processing jig for producing hemming of garment parts, which includes a fixed plate 1, a positioning plate 2 and a first bottom plate 3, and the positioning plate 2 is fixedly connected to the first bottom plate 3 , the side of the first bottom plate 3 close to the positioning plate 2 detours to form a first top plate 4, the space formed by the first top plate 4 and the first bottom plate 3 is covered with a second bottom plate 5, and the first top plate 4 is covered with a second bottom plate 5. The side of a top plate 4 away from the positioning plate 2 is connected to the second bottom plate 5, and the side of the second bottom plate 5 close to the positioning plate 2 is detoured to form a second top plate 6, and the second top plate 6 is connected to the The second bottom plate 5 is strip-shaped, a first channel is formed between the first bottom plate 3 and the second bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com