Manual louver valve

A louver valve and valve body technology, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as unreasonable design and defective details, and achieve the effect of reasonable design, small flow resistance, and small opening and closing torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

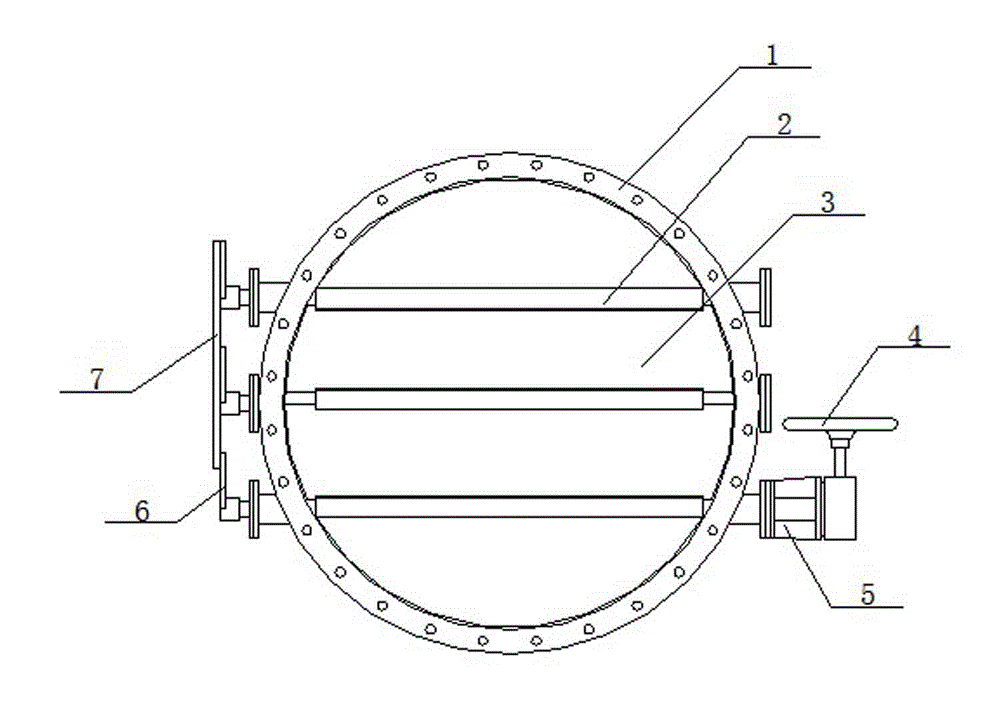

[0010] refer to figure 1 , this specific embodiment adopts the following technical solutions: a manual shutter valve, including a valve body 1, at least one rotatable valve shaft 2 is arranged in the valve body 1, and a valve shaft 2 is fixed on the valve shaft 2. Plate 3, and the valve plate 3 is matched with the valve body 1, so as to ensure good sealing performance when the valve plate 3 is closed; the handwheel 4 is arranged outside the valve body 1, and the valve shaft One end of the valve shaft 2 protrudes from the valve body 1 and is connected to the hand wheel 4 through the crank 5, and the other end of the valve shaft 2 protrudes from the valve body 1 and is connected to one end of the pull rod 6 , the other end of the tie rod 6 is connected to the connecting rod 7. It should be noted that the direction of the respective pull rods 6 corresponding to the valve shaft 2 is set in the same direction, so that the action of the connecting rod 7 drives other valve shafts 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com