An inductance detection method for multi-section and time-sharing measurement of blade profile

A detection method and multi-section technology, applied in electromagnetic measurement devices, electric/magnetic profile/curvature measurement, etc., can solve problems such as inability to measure blades and blade measurement cannot meet requirements, and achieve great economic and social value and technical effects. The effect of excellent, excellent technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

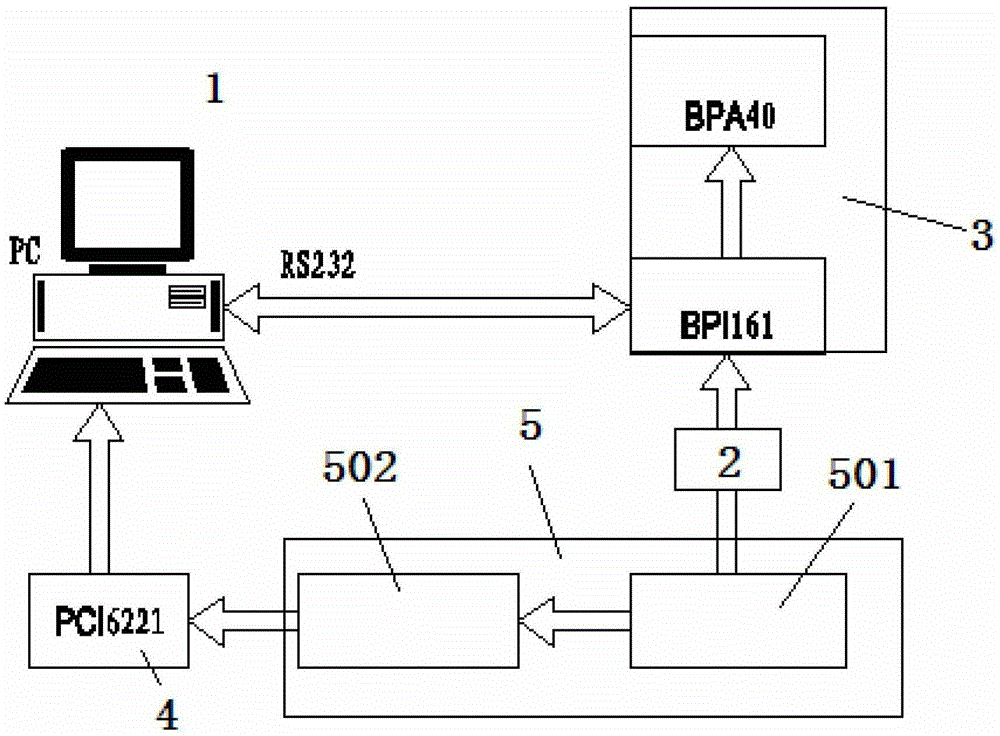

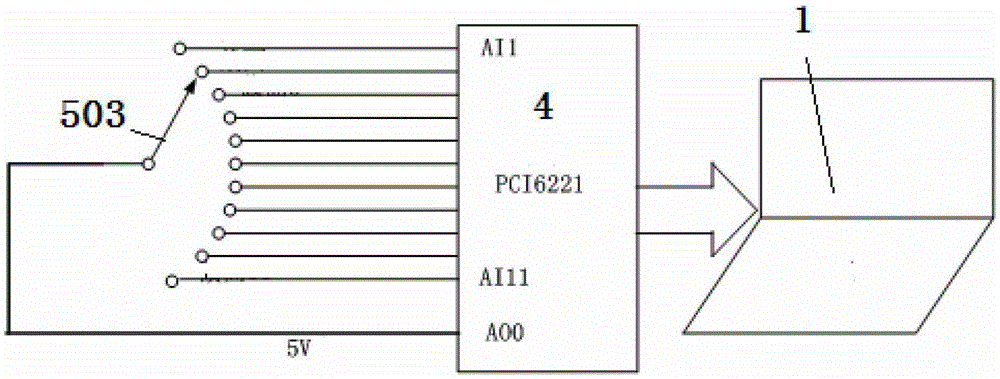

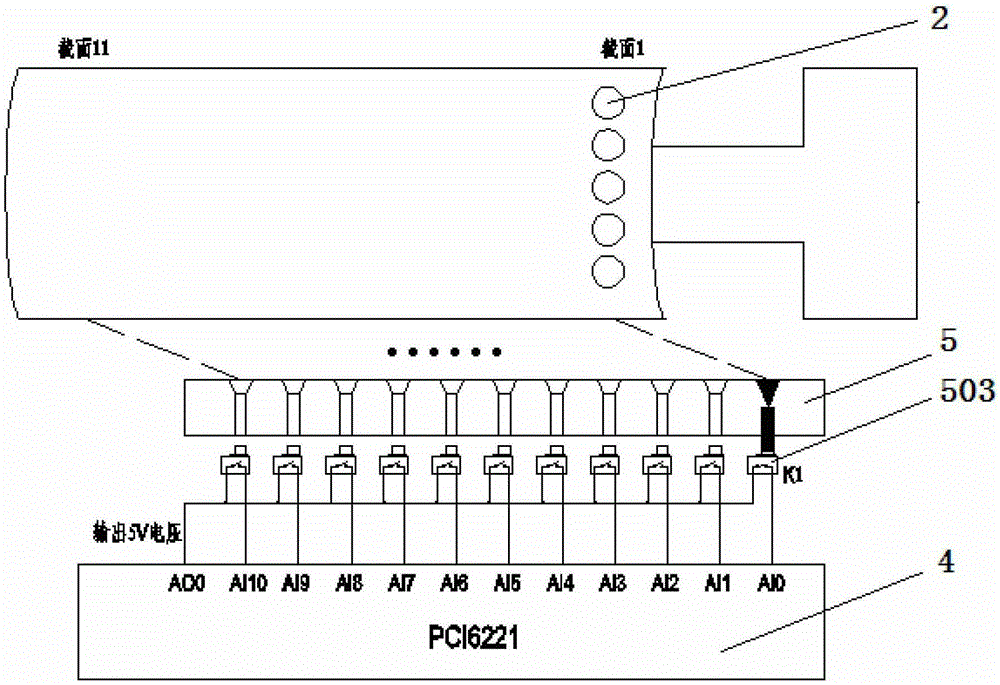

[0026] An inductance detection method for multi-section time-sharing measurement of the blade profile, which uses a special electrical measurement device for inductance detection, and the composition of the special electrical measurement device: industrial computer 1, inductance sensor 2, inductance detection equipment 3, section positioning circuit Module 4, blade and guide rail linkage mechanism 5; among them: industrial computer 1, inductance detection equipment 3, inductance sensor 2, blade and guide rail linkage mechanism 5, the blade under test, and section positioning circuit module 4 are sequentially connected in series, and the industrial computer 1 is also connected to the section positioning circuit module 4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com