Structural plane shear strength size effect testing device equivalence testing method

A technology of shear strength and test equipment, applied in the field of effectiveness testing, can solve problems such as inability to test equivalence, achieve great implementation value, social and economic benefits, and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The present invention will be further described below.

[0016] A method for testing the equivalence of a structural surface shear strength size effect test device, characterized in that: the test device is composed of n direct shear instruments, and the n direct shear instruments with test sizes ranging from small to large correspond to overlapping sample sizes L respectively 1 × L 1 , L 2 × L 2 ,...,L n-1 × L n-1 . The equivalence test method of the test device includes the following steps:

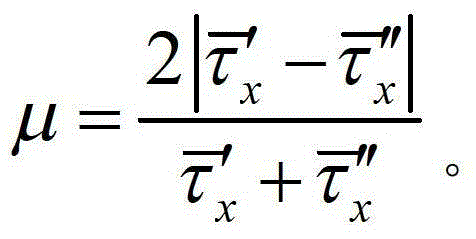

[0017] (1) Let the sample size be L x × L x is the overlap size of two direct shear instruments, where (X=1~n-1). Sample size is L x × L x The same rock mass structural plane was tested for shear strength on direct shear instruments of different sizes (a total of two direct shear instruments). According to the water conservancy and hydropower engineering rock test regulations (DL / T5368-2007), a relatively small direct shear instrument (denoted as the xth direct shear ...

example

[0022] The sample size span of the test is (100mm×100mm-1000mm×1000mm), the load span is 2-1000kN, and the load span is 500 times. The series of direct shear instruments are composed of two direct shear instruments, one small direct shear instrument can test the structural surface sample range of 100mm×100mm-400mm×400mm; the other large direct shear instrument can test the structural surface sample range of 400mm ×400mm-1000mm×1000mm; the size of the same structural surface sample that can be measured by two direct shear instruments is 400mm×400mm.

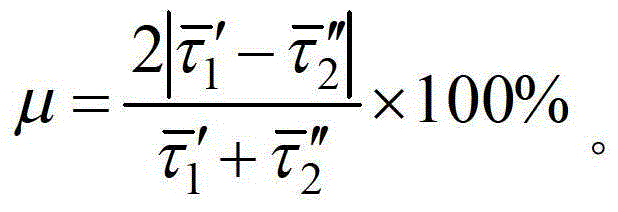

[0023]Take 16 groups of model structural surface samples with the size of 400mm×400mm and the same physical and mechanical properties. Among them, 8 groups carried out the direct shear test under the same normal stress on the small direct shear instrument, and the measured shear strength with 95% guarantee rate was taken as the average value, which was recorded as The other 8 groups carried out the direct shear test under the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com