Energy-saving screen door system for rail transit platforms

A rail transit and screen door technology, applied in the direction of ventilation arrangement, war damage prevention, etc., can solve the problems of energy saving and emission reduction, high power consumption, difficulty in providing energy saving, comfortable and beautiful waiting environment, etc., and achieve uniform Sexual requirements, saving working time, satisfying the aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

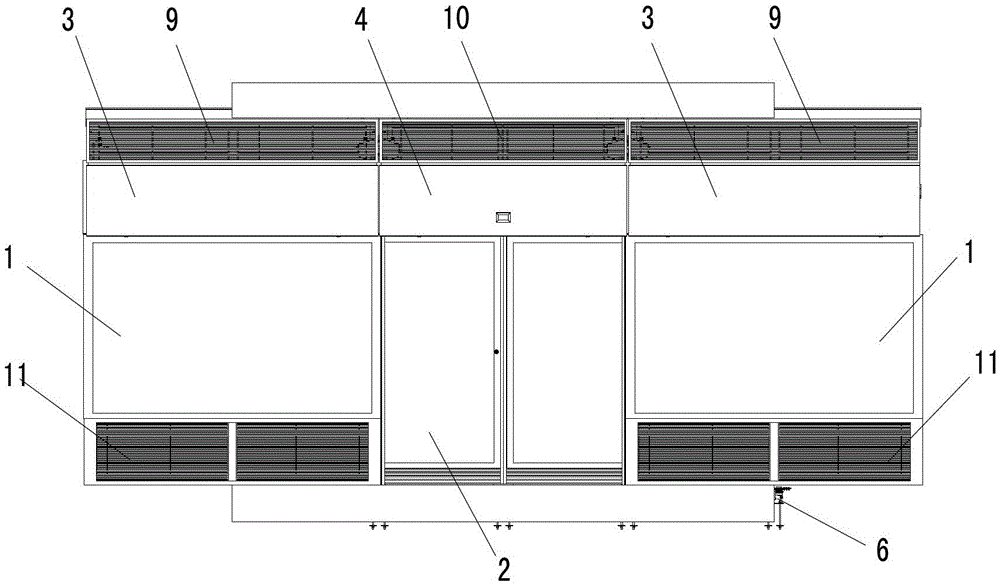

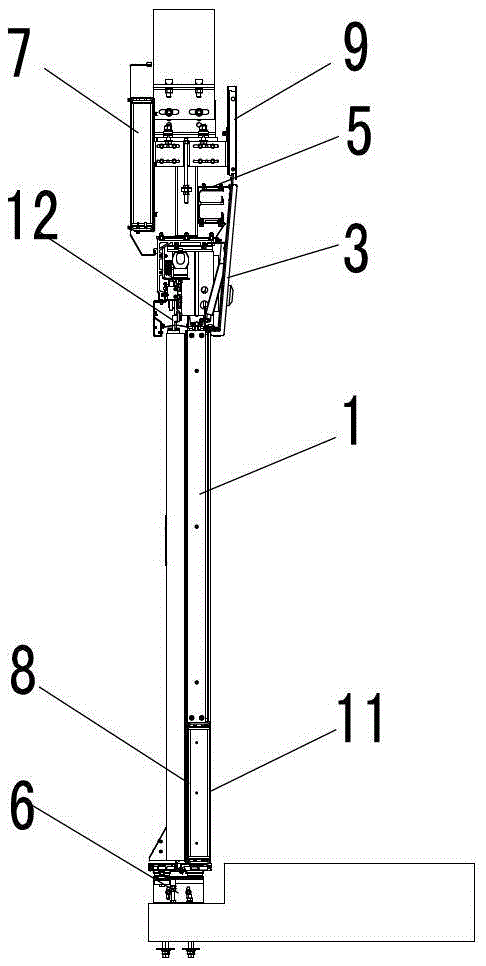

[0017] see figure 1 , figure 2 , the rail transit platform energy-saving screen door system of the present invention includes a screen door body composed of a fixed door 1, a sliding door 2, a fixed door front cover 3, a sliding door front cover 4, an upper connecting structure 5 and a lower supporting structure 6 structure. Vents are respectively arranged above the fixed door and the sliding door, and energy-saving air valves 7 are respectively installed in each air vents, and air vents are arranged at the bottom of the fixed door, and energy-saving air valves 8 are installed in the air vents. Corresponding positions are equipped with ventilation louvers respectively, including ventilation louvers 9 above the fixed door, ventilation louvers 10 above the sliding door and ventilation louvers 11 at the bottom of the fixed door.

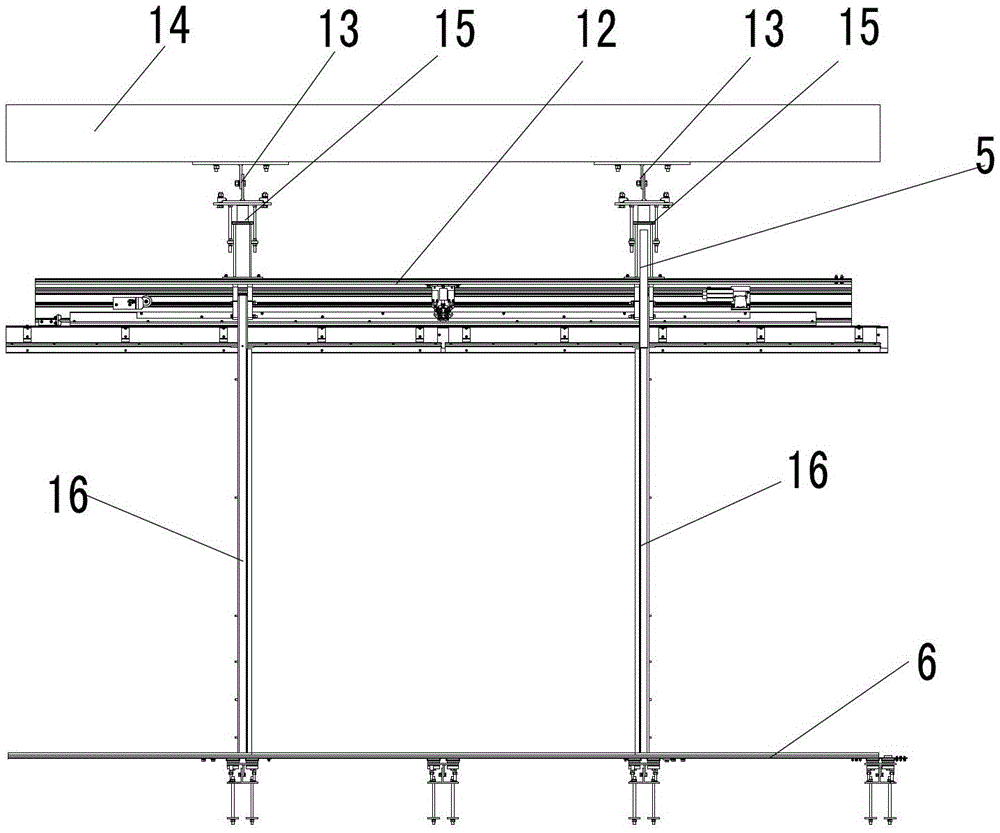

[0018] The energy-saving air valve 7 located above the fixed door and the sliding door is arranged on the inner side of the upper connection structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com