iter—pf conductor four-roller single pass flat compression diameter forming machine

A molding machine and roller technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of high molding force, damage, and adhesive armor surface, etc., to achieve high bearing capacity, simple principle, and avoid damage Conductor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

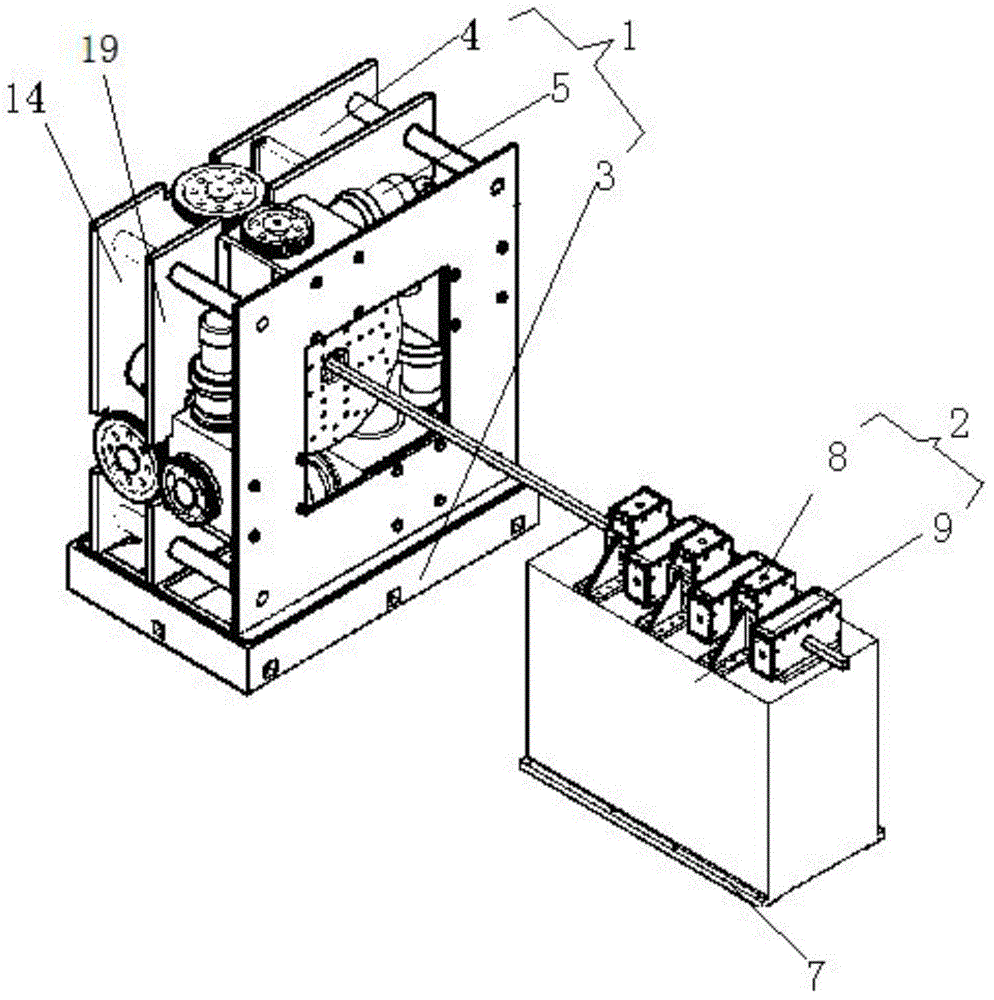

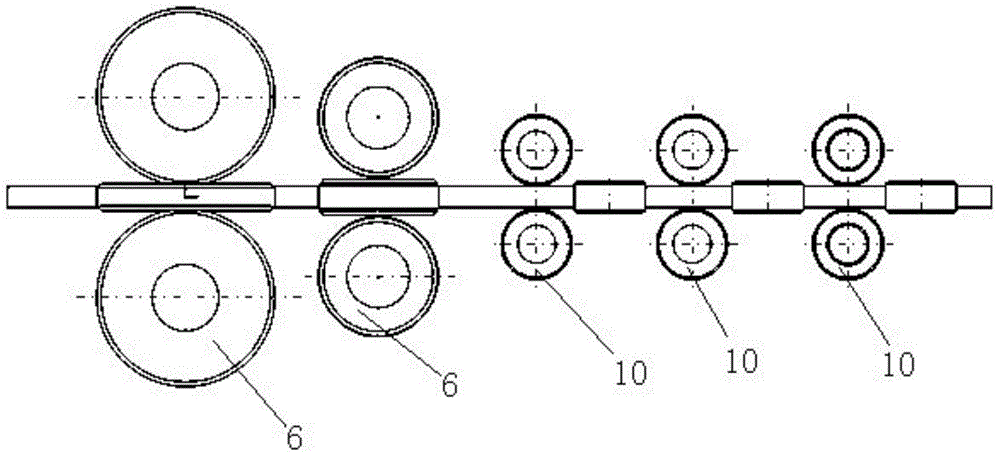

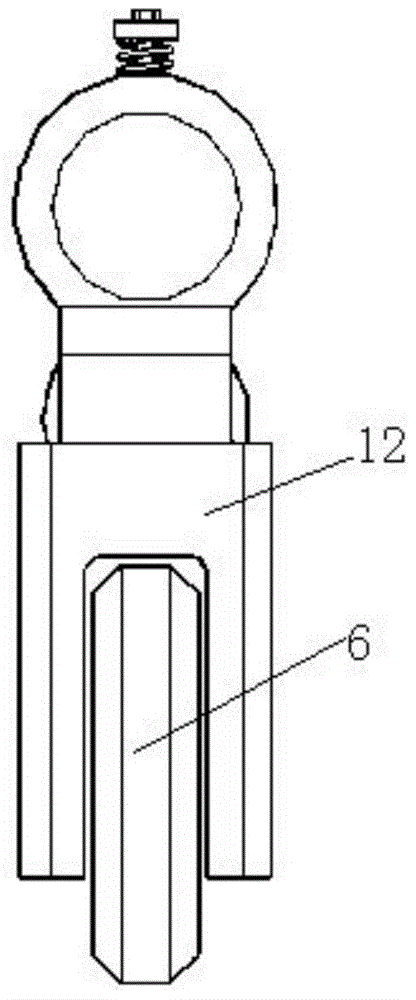

[0024] Referring to the accompanying drawings, an ITER-PF conductor four-roller single-pass flat compression diameter forming machine includes a forming device 1 and a straightening device 2 that cooperate with each other. The forming device 1 includes a base 3 on which an active forming device is erected. The device 4 and the passive forming device 5, the active forming device 4 and the passive forming device 5 respectively include four rollers 6, and the four rollers 6 all surround the same reference line, and are respectively in the circumferential direction of the two positions of the reference line. The cloth and the rollers 6 are respectively adjustable at positions perpendicular to the reference line, and a square forming channel for the conductor to enter is formed between the inner wheel surfaces of the active forming device 4 and the passive forming device 5; the straightening device 2 Located behind the molding device 1, it includes a support 7 on which three sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com