3D printing sprayer

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve the problems of limited spraying speed, inability to depict details, and inability to guarantee the accuracy of the printing process, and achieve good molding speed, molding effect, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

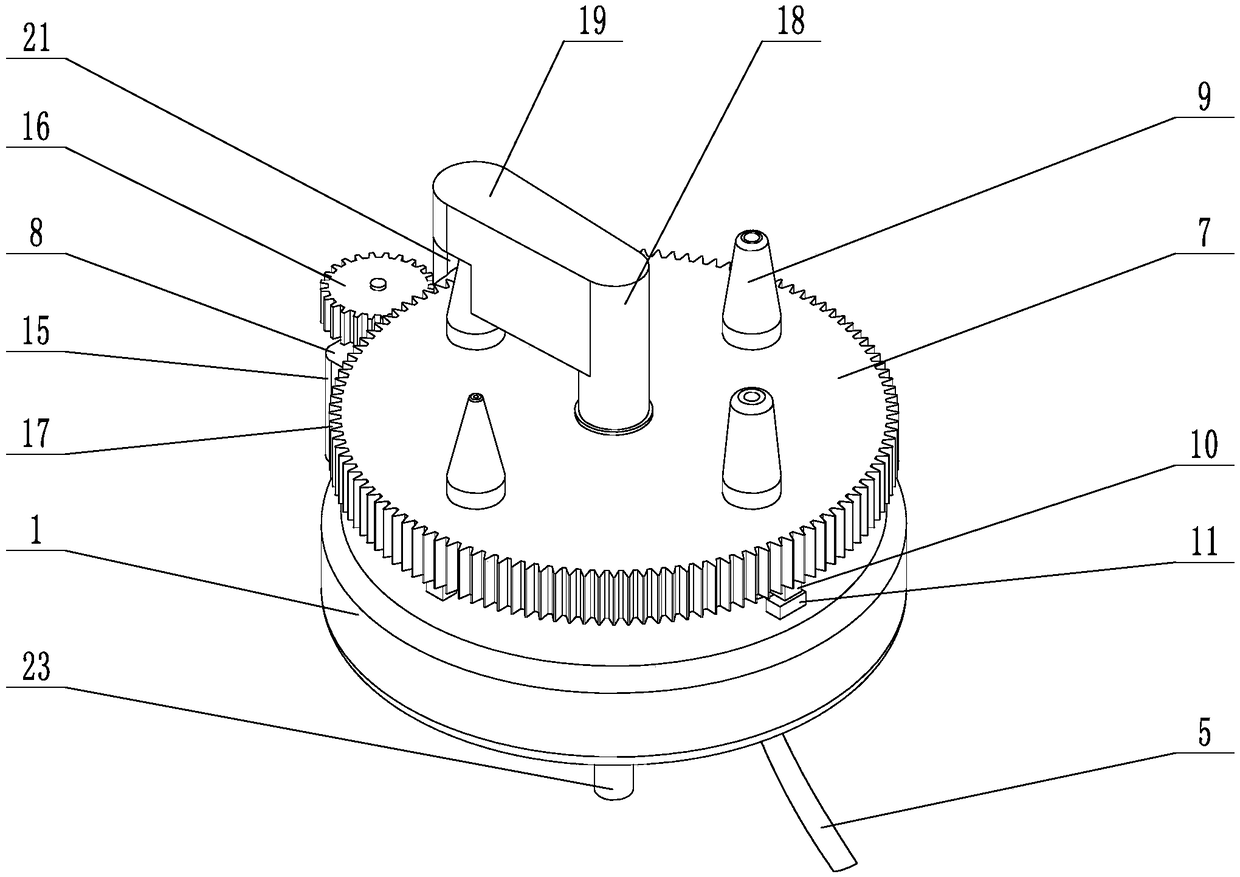

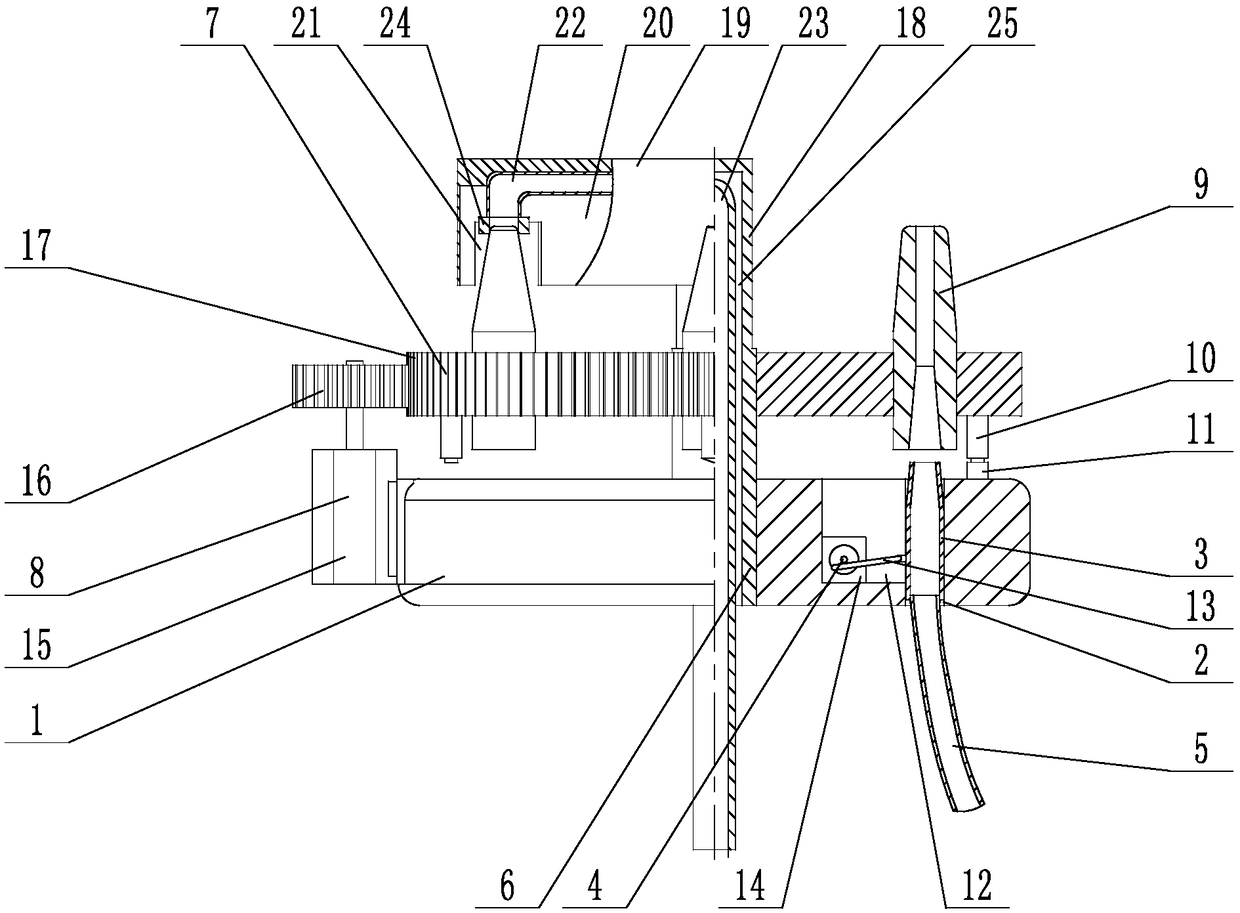

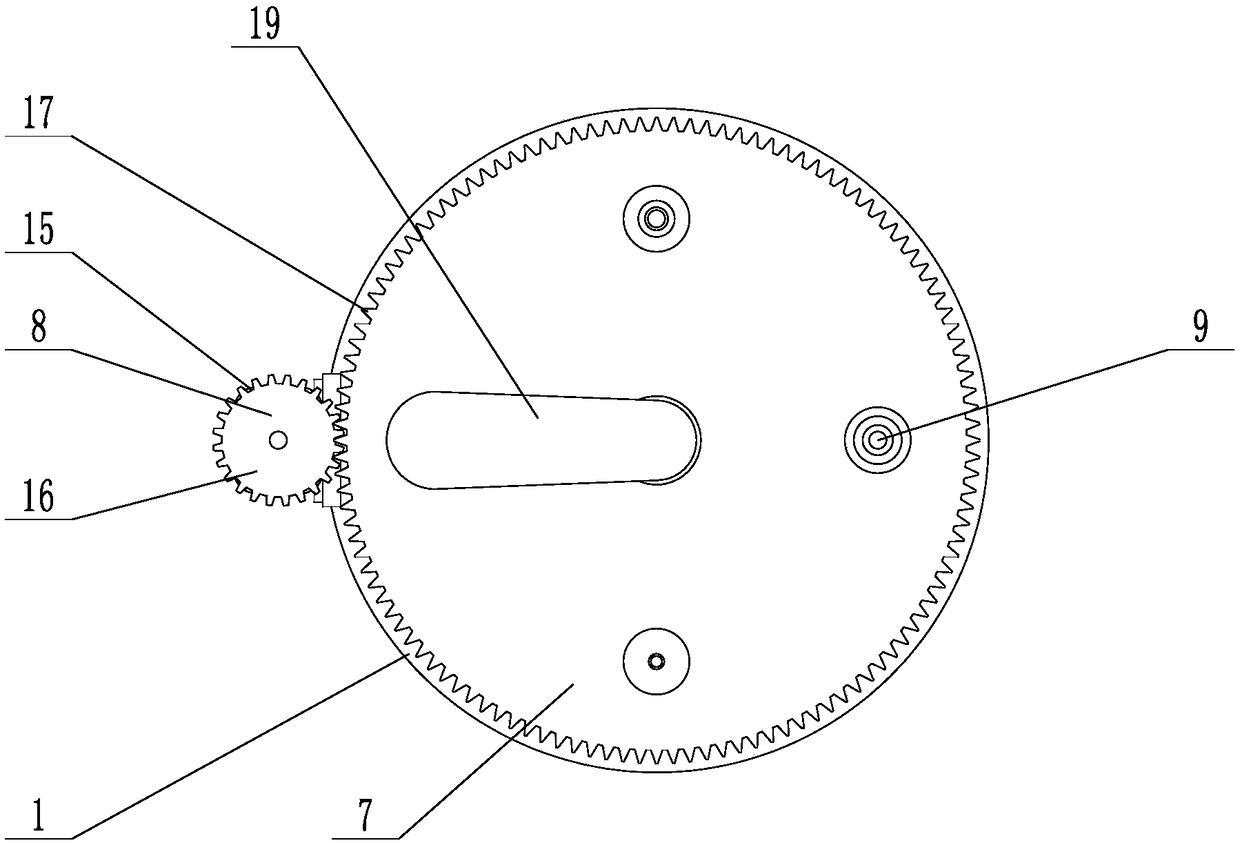

[0069] When the present invention is in use, the 3D printer controller imports the set program in advance, and the 3D printer controller controls the action of the second driving device 8, so that the rotating disk 7 rotates along the fixed axis 6, and the nozzles 9 on the rotating disk 7 follow the rotation of the rotating disk. 7 rotation, when the pre-set nozzle 9 rotates to the position matched with the retractable nozzle 3, the sensor 10 corresponding to the nozzle 9 is in contact with the trigger 11, and the sensor transmits the signal to the 3D printer controller, the 3D printer The controller controls the second driving device 8 to stop, so that the nozzle 9 stops at the coaxial position with the telescopic nozzle 3, and then the 3D printer controller controls the first driving device 4 to move, and the first driving device 4 drives the telescopic nozzle 3 to a fixed position. The mounting hole 2 on the disk 1 slides inside, so that the head of the telescopic nozzle 3 i...

Embodiment

[0071] A 3D printing nozzle, comprising a fixed plate 1, an installation hole 2 is provided on the fixed plate 1; a telescopic nozzle 3 is arranged in the installation hole, and the telescopic nozzle 3 can slide in the installation hole 2; The first driving device 4 connected with the signal of the 3D printer controller is set, the first driving device 4 is compatible with the telescopic nozzle 3, and the first driving device 4 is used to drive the telescopic nozzle 3 to slide in the installation hole 2, this In the embodiment, the first driving device 4 includes a mounting groove 12, the mounting groove 12 is located on one side of the mounting hole 2, a connecting rod 13 and a first motor 14 are arranged in the mounting groove, and one end of the connecting rod 13 is connected to the telescopic The nozzle 3 is hinged, the first motor 14 is fixed to the side wall of the installation groove 12 by bolts, the first motor 14 is connected to the 3D printer controller signal, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com