Wire connector

A wire connector and main connection technology, which is applied in the direction of connections, current collectors, contact parts, etc., can solve problems such as poor connection stability and potential safety hazards of metal conductive strips, and achieve improved stability, convenience and safety, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

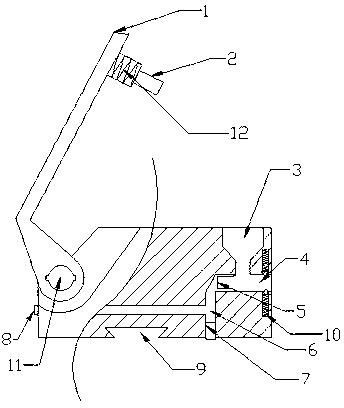

[0030] Further description will be made below in conjunction with the accompanying drawings,

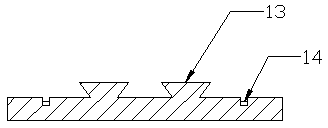

[0031] Such as figure 1 As shown, the present invention includes a rotating arm 1, a pressing block 2, a pressing opening 3, a wire groove 4, a wire contact 5, a conductive metal sheet 6, a hollow rotating shaft 11, a main connecting contact 7 and a secondary connecting contact 8, The base of the connector is a rectangular parallelepiped. On one of the edges of the rectangular parallelepiped, there is a rotating arm 1 that can elastically rotate around the base. On the rotating arm 1, a pressing block 2 is arranged. 12 Elastic connection, a press-in opening 3 is processed on the base, by turning the rotating arm 1, the pressing block 2 on the rotating arm 1 is pressed into the pressing-in opening 3 on the base, inside the base, the pressing block 2 is pressed into the opening The bottom of the hole 3 is also provided with a wire groove 4 perpendicular to the axis of the press-in hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com