Load cell and method for adjusting a load cell

A weighing sensor and weighing system technology, applied in the field of weighing sensors, can solve problems such as the possibility of designing unfavorable load joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

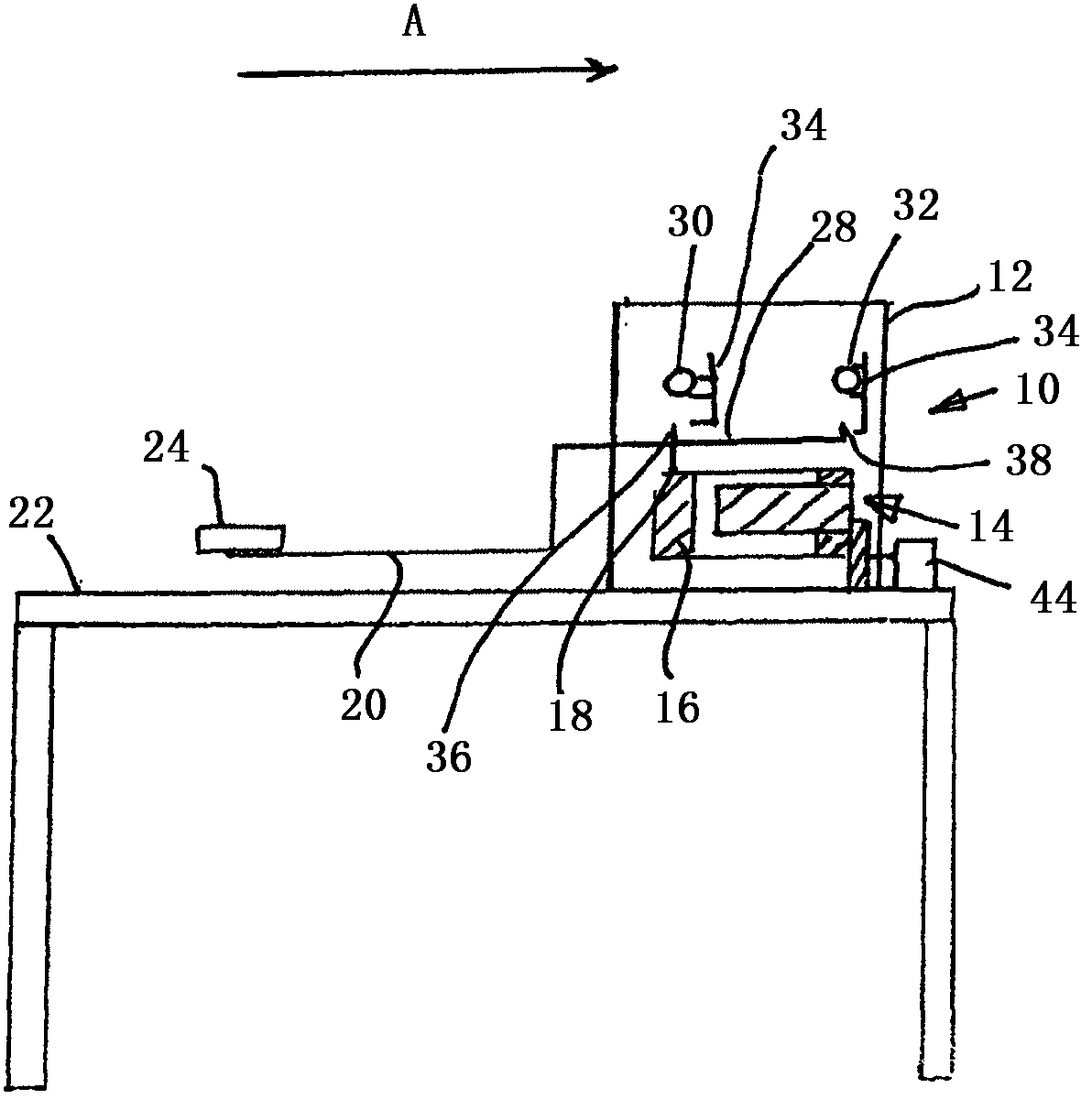

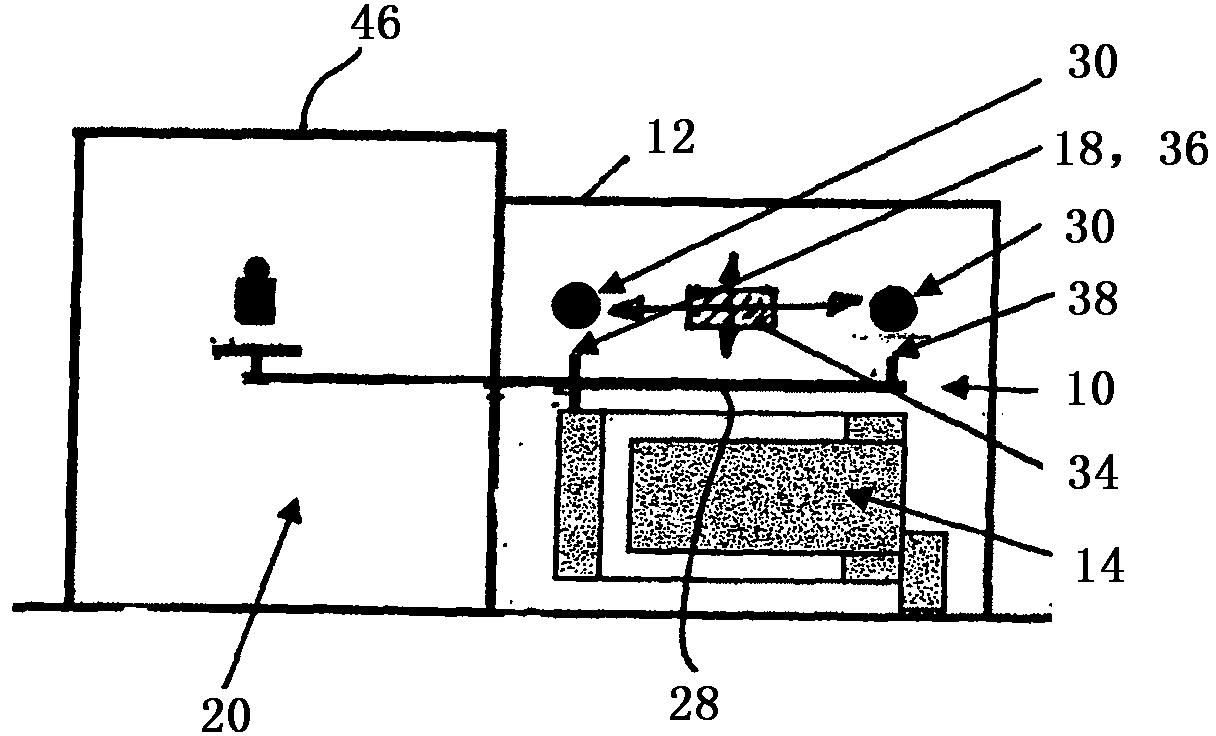

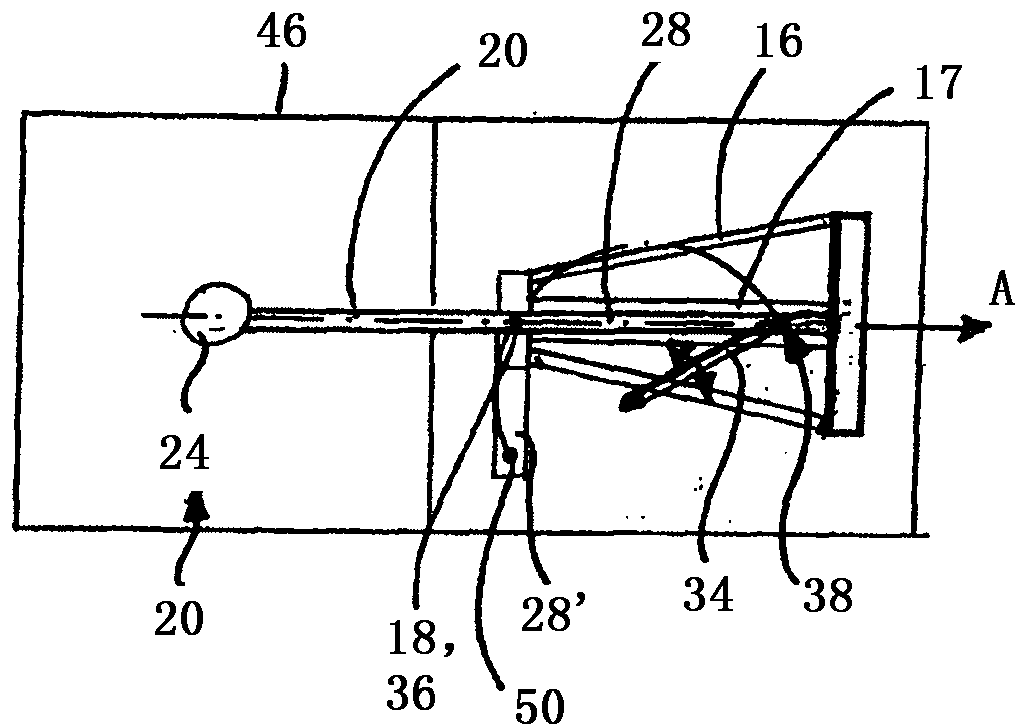

[0032] figure 1 A load cell 10 is shown with a housing 12 . Inside the housing 12 is a weighing system 14, which preferably includes a parallelogram 16 that transmits the applied load to a weighing boom 17 (see image 3 ).

[0033]At one end of the parallelogram 16 there is a point of application 18 at which a load boom arm 20 protruding from the housing is incorporated into the weighing system.

[0034] The load boom arm 20 preferably extends horizontally within the housing 12 and is angled downwardly outside the housing 12 such that said downwardly angled portion extends adjacent to and along the table top 22 .

[0035] The distance between the downwardly angled portion of the load boom arm 20 and the table top 22 is minimal.

[0036] Attached to one end of the load boom arm 20 is a plate 24 capable of containing the item to be weighed.

[0037] The load boom arm 20 is releasably secured by, for example, a connector (not shown).

[0038] As a top view ( image 3 ), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com