An anti-vibration connector for battery replacement of electric passenger car chassis

A connector and passenger vehicle technology, applied in electric power units, power units, vehicle components, etc., can solve the problems of long time consumption, fire and combustion, and high local temperature, achieve stable and reliable working process, and avoid connector disconnection , to avoid the effect of fretting and instantaneous interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

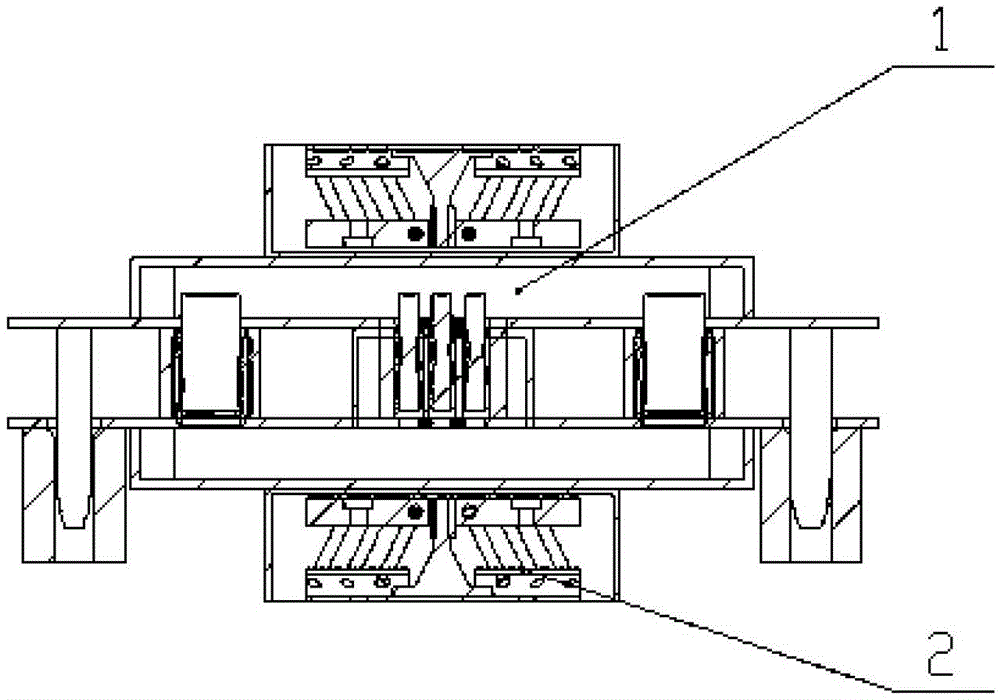

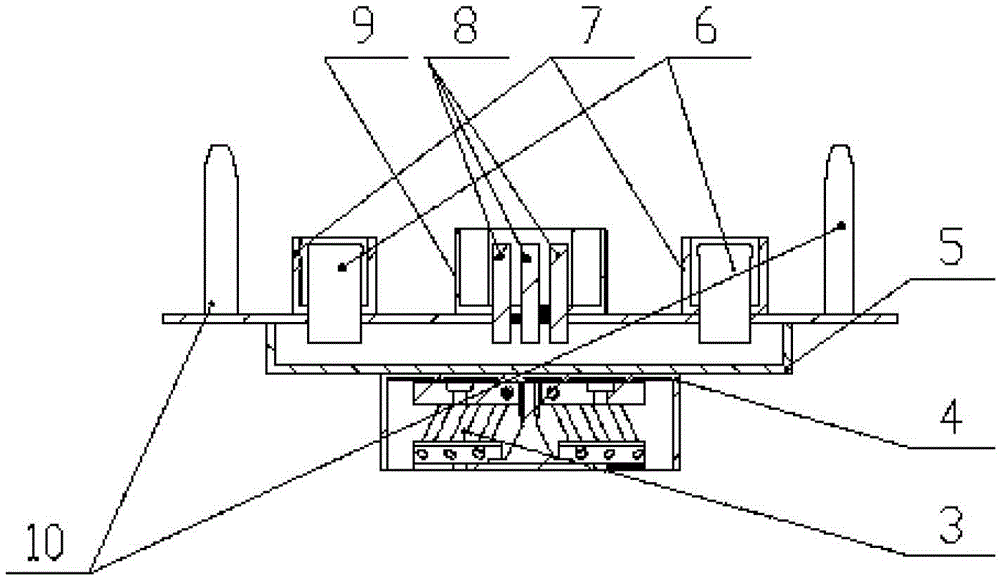

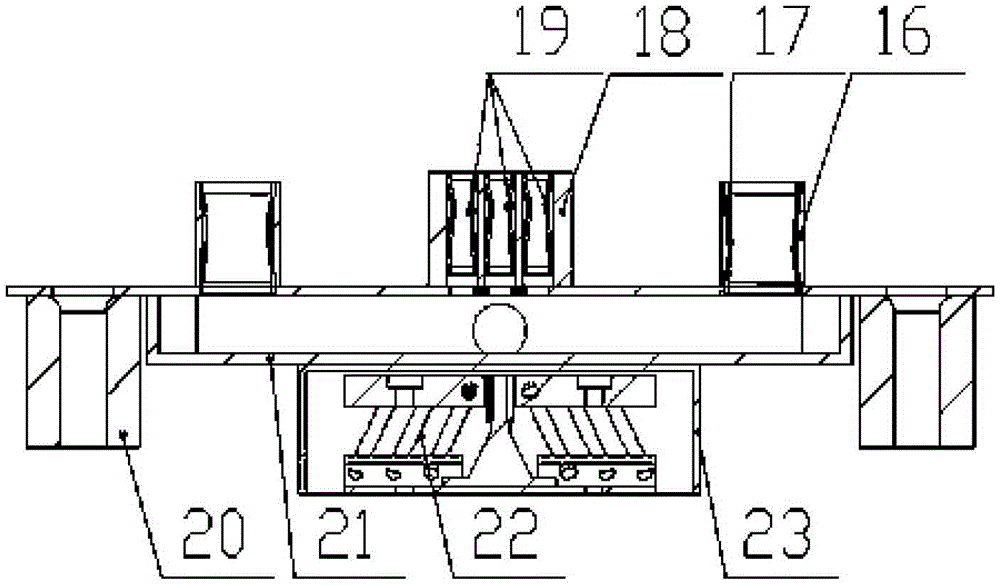

[0039] like Figure 1-Figure 3 , providing an anti-vibration connector for electric passenger car chassis replacement, the connector includes a male board 1 and a mother board 2; the male board 1 includes a main panel 5 provided on the male board and a The communication plug 8 on the main panel 5 provided on the top, the strong electric plug 6, the positioning pin 10 and the connecting seat provided on the male board, the motherboard 2 includes the main panel 21 provided on the motherboard and the main panel installed on the motherboard. The communication socket 18 on the main panel 21 provided, the strong electric socket 16, the positioning pin socket 20 and the connection seat provided on the motherboard; the communication socket 8, the strong electric socket 6 and the positioning pin 10 are respectively inserted into the corresponding socket.

[0040] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com