Processing device for producing 2-picoline

A processing device and a technology for picoline, which are applied in the field of processing devices for producing 2-picoline, can solve the problems of limited volume, non-continuous processing production, discontinuity in 2-picoline processing and production, and the like, achieving The production efficiency is improved, the structure is reasonable, and the use effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

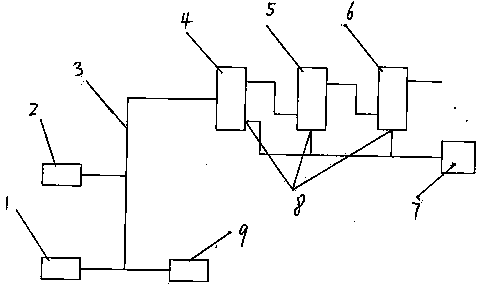

[0007] Describe embodiment in detail in conjunction with accompanying drawing, a kind of processing device of producing 2-picoline, it comprises reactor 4,5,6, and acetylene compressor 2 passes into first reactor 4 through pipeline 3, and acetonitrile generator 1 passes through The pipeline leads into the first reactor 4, the catalyst generator 9 passes into the first reactor 4 through the pipeline, the first reactor is connected with the second reactor 5 through the pipeline, and the second reactor 5 is connected with the third reactor 6 through the pipeline. Connection, the third reactor is provided with a material outlet, and the first reactor 4, the second reactor 5, and the third reactor 6 are all provided with a residual material outlet 8. This structure allows the raw materials to continuously enter each reactor, fully react in each reactor, and finally discharge the formed 2-picoline from the discharge port, and at the same time, the insufficiently reacted remaining mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com