Foam huff and puff sand discharging experiment device and method based on integration of well hole and oil reservoir

An experimental device and foam technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as ideal assumptions, inability to simulate wellbore flow characteristics, and inability to complete simulations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

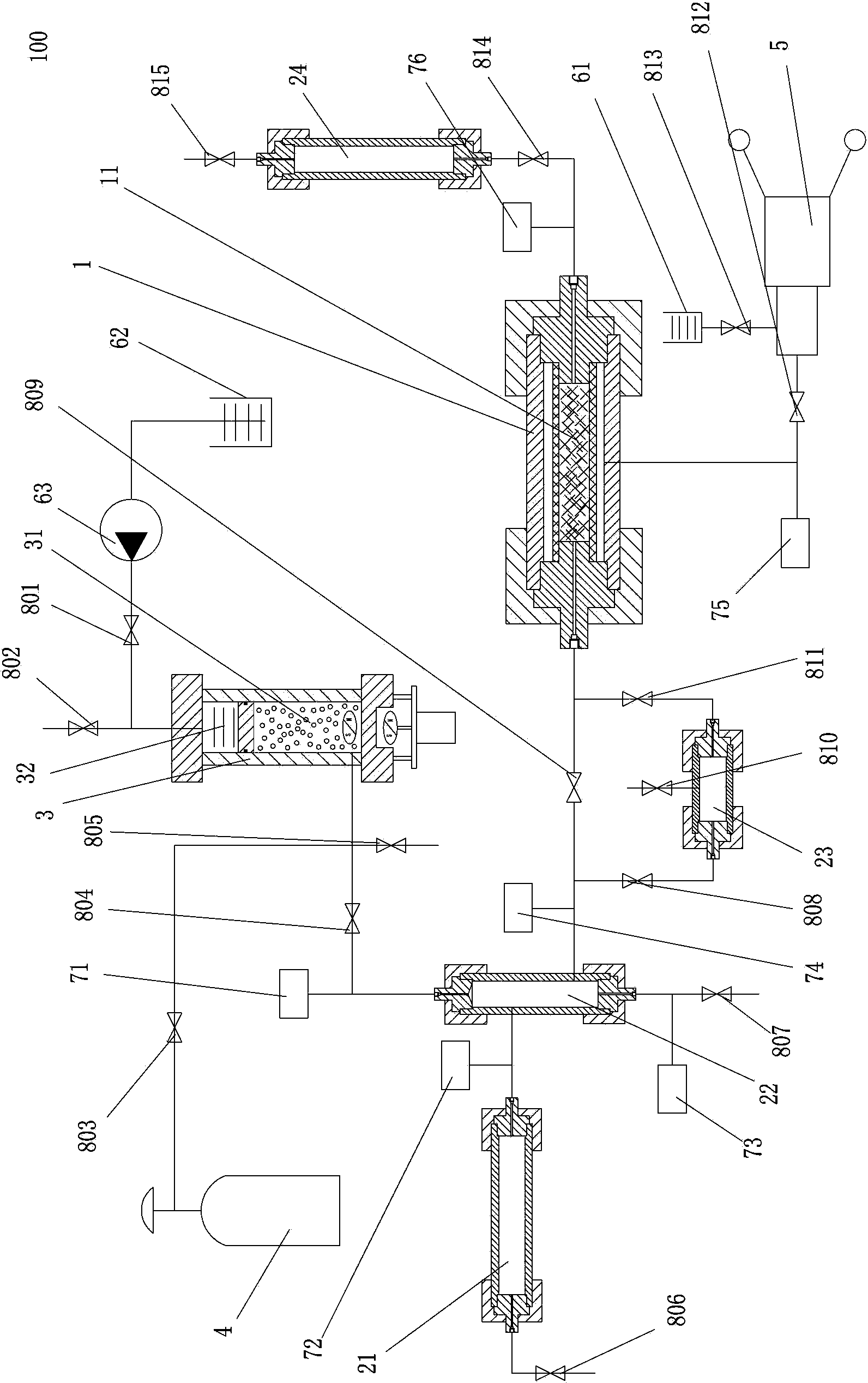

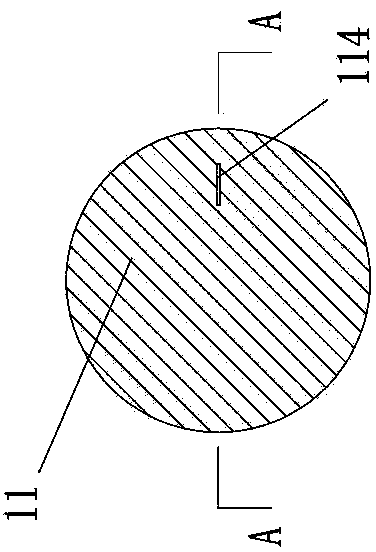

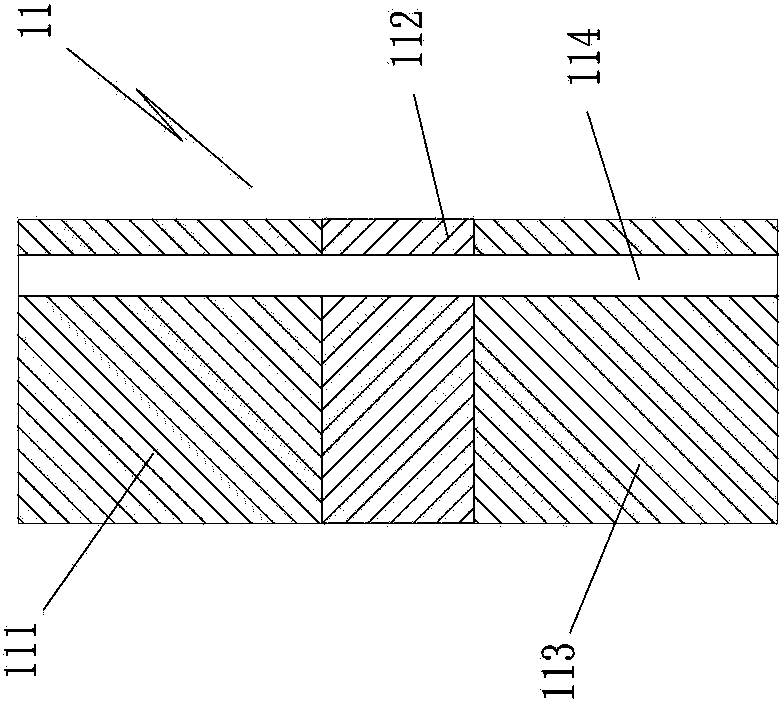

[0043] Such as figure 1As shown, the present invention proposes a foam huff and puff sand discharge experimental device 100 based on the integration of wellbore and reservoir; the experimental device 100 includes a core holder 1, and the artificial Rock core 11; one end of the core holder 1 communicates with a side wall of a second sand-filling pipe 22 used to simulate a wellbore through a ninth valve 809, and the sidewall of the second sand-packing pipe 22 also communicates with a sidewall of a second sand-filling pipe 22 used to simulate a wellbore One end of the first sand filling pipe 21 in the buffer space, the end of the first sand filling pipe 21 is provided with a second pressure sensor 72, and the other end of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com