Overflow safety valve of aviation hydraulic system

A technology of hydraulic system and safety valve, which is applied in the field of improvement of overflow safety valve of aviation hydraulic system, can solve problems such as shortening the service life of safety valve, blockage of orifice, failure of normal reset of safety valve, etc., so as to reduce the number of product maintenance or replacement. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

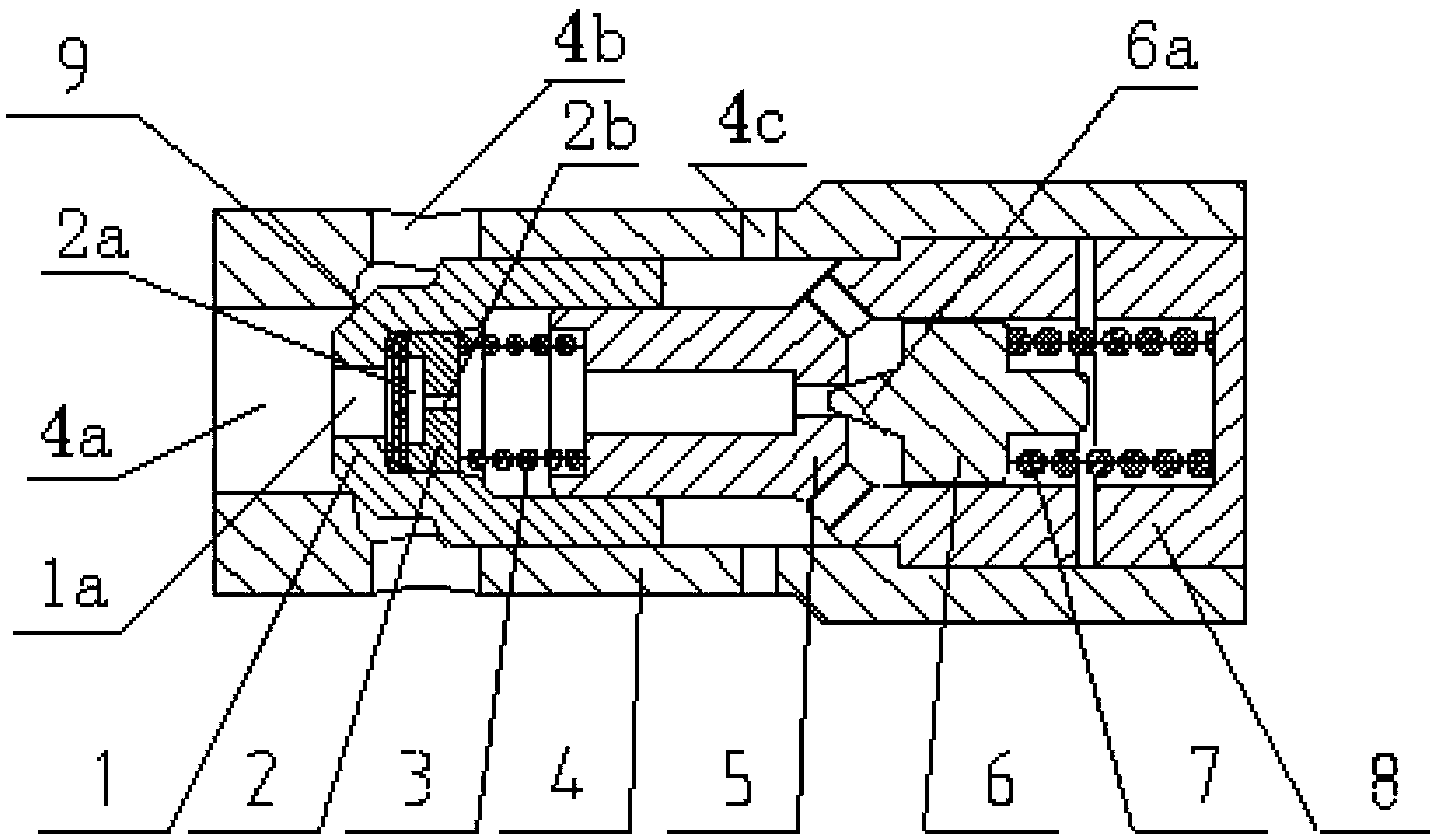

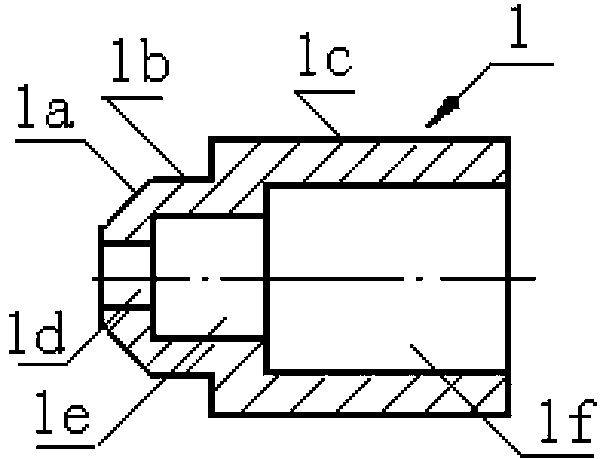

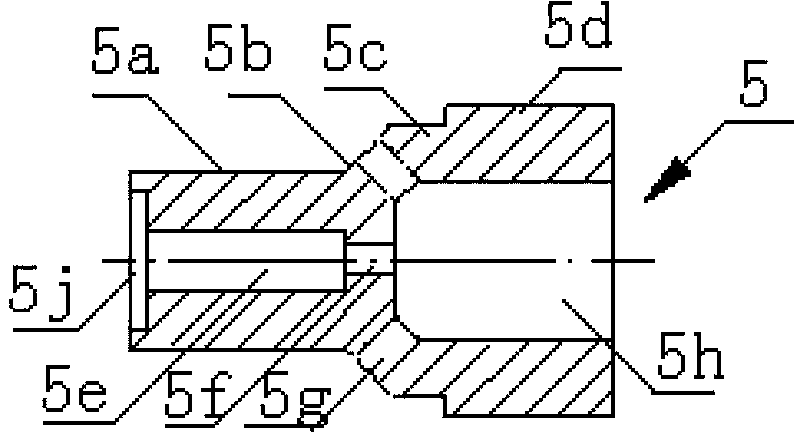

[0017] The present invention will be described in further detail below. see Figure 1 to Figure 4, an aviation hydraulic system overflow safety valve, is composed of a housing 4, a main valve mechanism installed in the left part of the inner cavity of the housing 4, and a pilot valve installed in the right part of the inner cavity of the housing 4; the housing 4 is a round There is an external thread on the right part of the outer cylindrical surface of the housing 4. The inner hole of the housing 4 is a two-stage stepped hole 4a. The left section hole with the smallest inner diameter of the two-stage stepped hole 4a is the oil inlet. The right port forms the valve seat of the main valve mechanism, and the right section hole of the two-stage step hole 4a is a threaded hole with an inner diameter larger than the middle section hole. The main valve mechanism oil outlet 4b through which the middle hole of the two-stage stepped hole 4a is connected. A pilot valve oil outlet 4c t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com