Personalized packaging production system

A technology for producing systems, pallets, applied in packaging, transport and packaging, manufacturing of rigid/semi-rigid containers, etc., capable of solving problems such as cutting pens stuck on sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

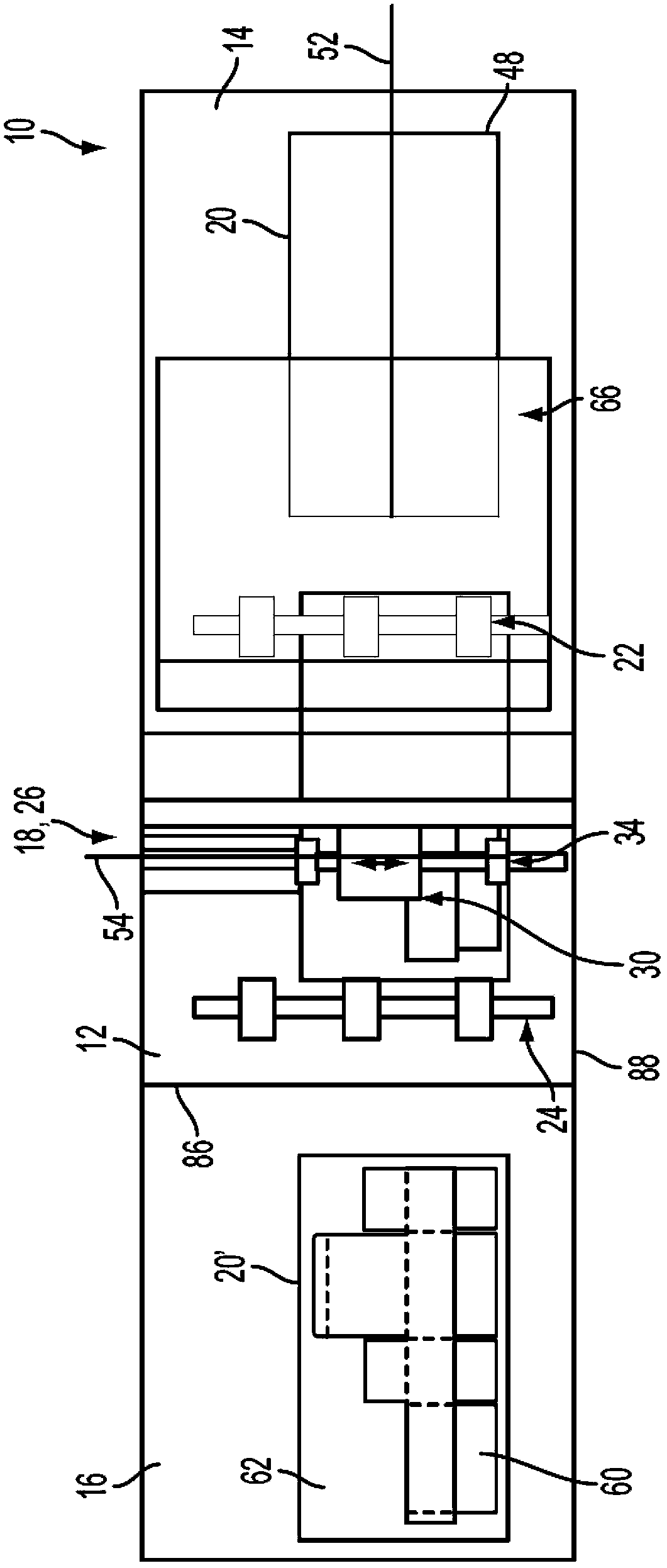

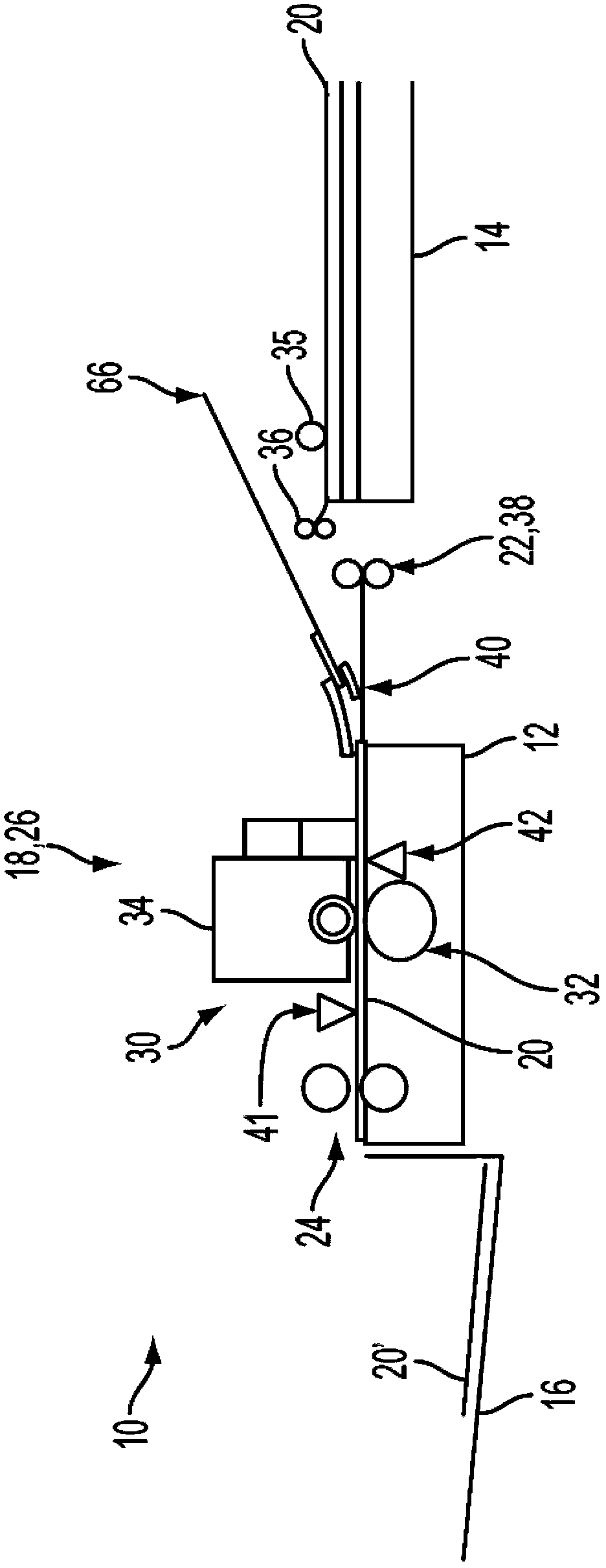

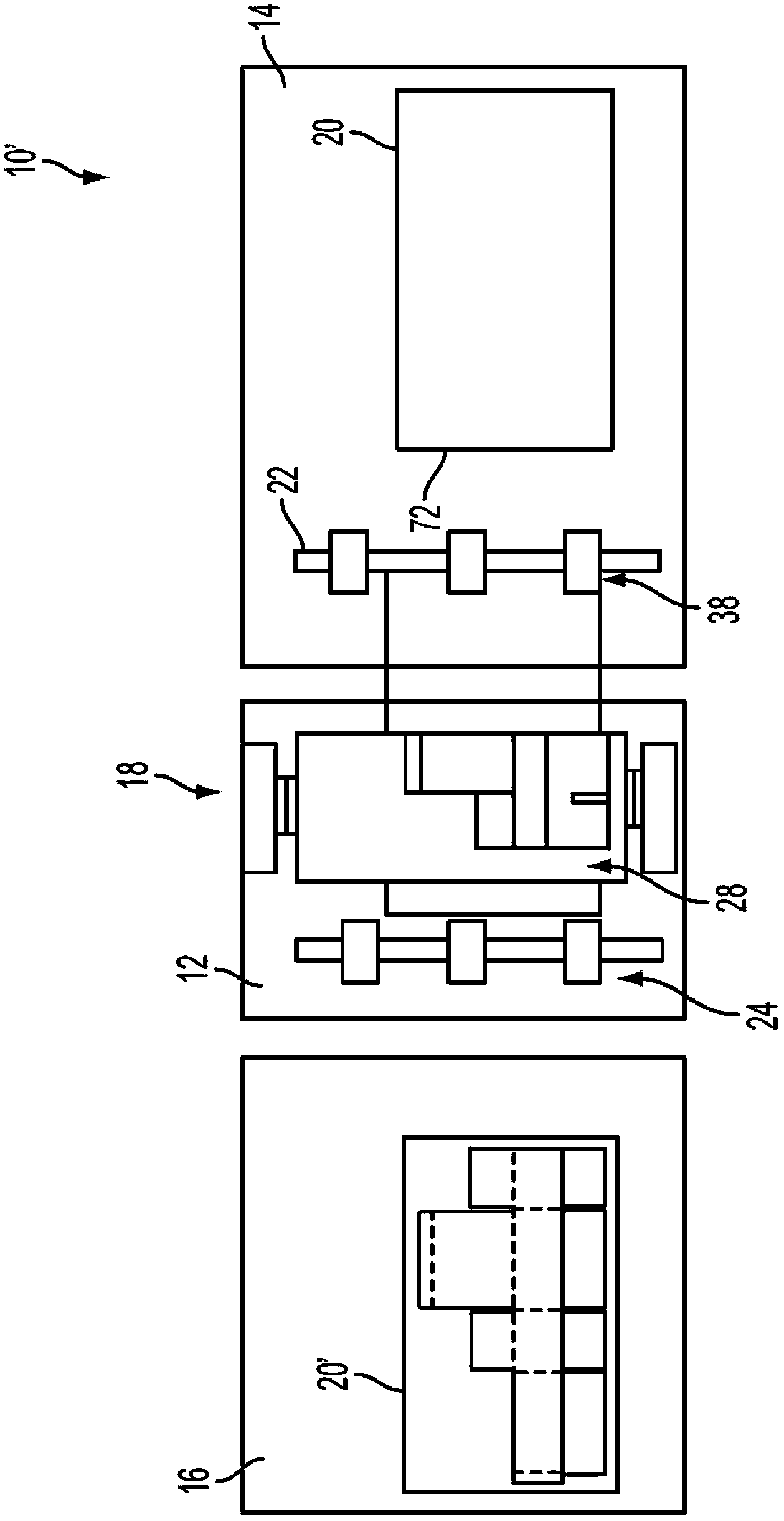

[0012] Referring to the drawings, wherein like numerals represent like parts throughout the figures, a system of personalized packaging production according to the present disclosure is generally indicated by the numerals 10, 10".

[0013] The personalized packaging production system 10, 10" includes a cutting station 12 arranged intermediate an infeed tray 14 and an outtake tray out 16. A cutting / creasing assembly 18 is arranged above the cutting station 12 to enable cutting and / or creasing (described below) media sheet 20 placed on cutting table 12. A sheet feeder positioned between in-feed tray 14 and cutting table 12 feeds raw media sheet 20 from in-feed tray 14 to Cutting station 12 , and exit clamp 24 positioned between exit tray 16 and cutting station 12 transfers processed media sheet 20 ″ from cutting station 12 to exit tray 16 .

[0014] refer to figure 1 , figure 2 and Figure 7 , the cutting / creasing assembly 18 of the first embodiment 10 of the personalized pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com