Paper processing apparatus

A paper processing device and paper technology, applied to printing devices, printing, typewriters, etc., can solve the problems of multi-page paper 15 damage, curled part 151 refolding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

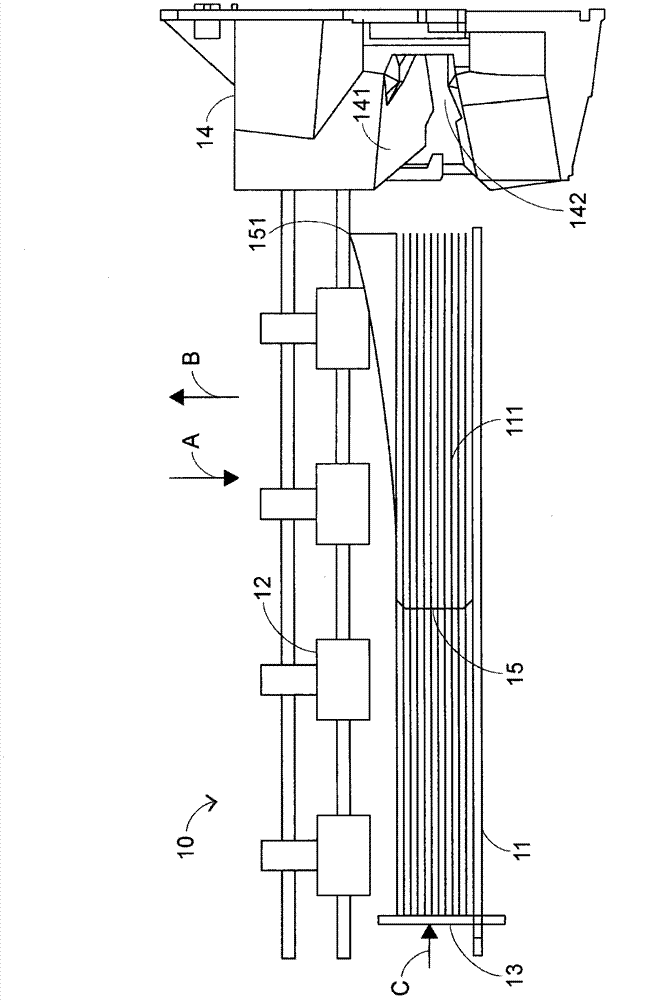

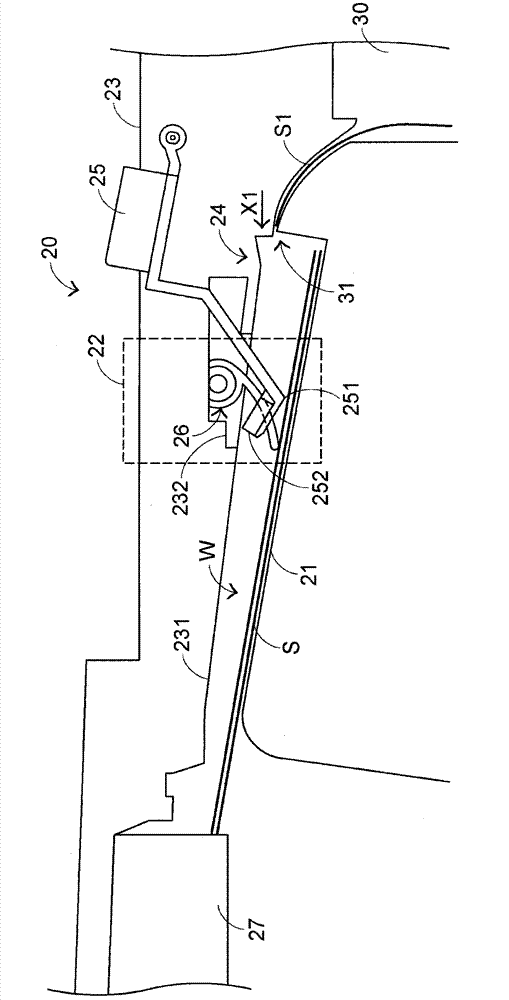

[0050] Please refer to figure 2 , figure 2 It is a schematic diagram of the printing device and the paper processing device of the present invention. like figure 2 As shown, the paper processing device 20 of the present invention is installed at a paper outlet 31 of a printing device 30 for stapling multiple sheets of paper S fed out from the printing device 30 .

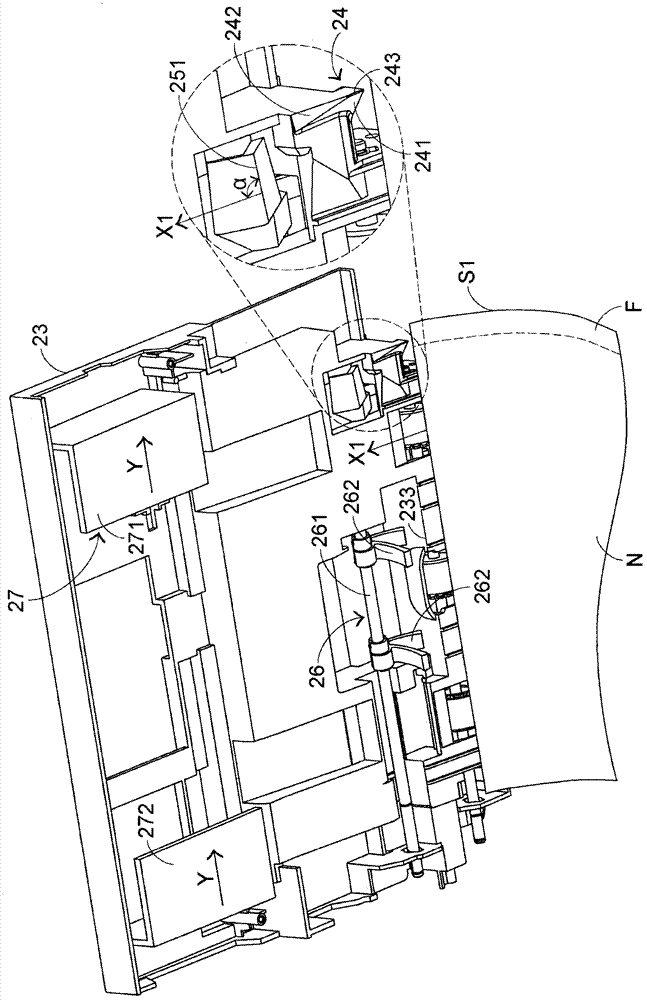

[0051] The paper processing device 20 includes a paper tray 21, a stapler 22, a housing 23, a convex portion 24, a swing arm 25, a first paper alignment mechanism 26, a second paper alignment mechanism 27, and a paper feeding channel W, wherein the casing 23 has a lower surface 231 and a limiting structure 232 , and the swing arm 25 has a bent portion 251 and an end 252 .

[0052] Please refer to image 3 , image 3 It is a bottom view of the paper processing device of the present invention. like image 3 As shown, housing 23 has an aligned edge 233 . The protrusion 24 includes a slope 241 , a contact por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com