Processing method for gasket of deck cabin of vessel

A ship deck and processing method technology, applied to ship parts, ship construction, ships, etc., can solve the problems of time-consuming and labor-intensive, difficult to ensure the surface of the gasket, and the corner of the gasket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

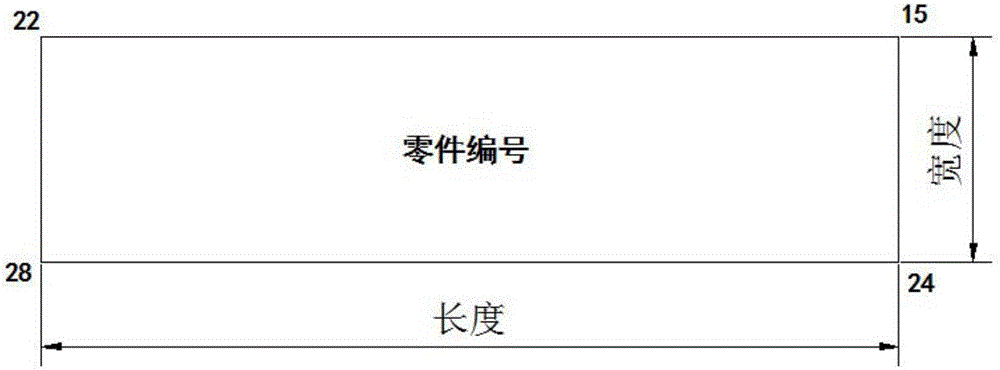

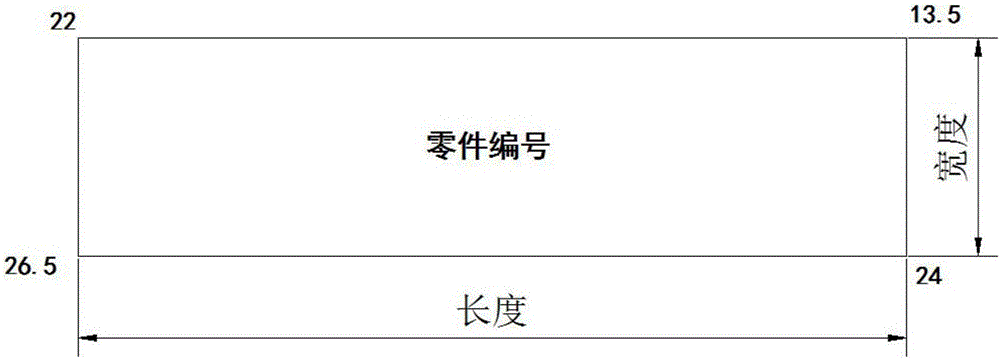

[0023] see figure 1 , The invention discloses a processing method of a ship deck cabin gasket, which is used for the gasket processing of a ship with a deck cabin. The invention mainly includes a processing and measurement method of the deck cabin gasket, and the processing data adjustment of the deck cabin gasket. method.

[0024] In the present invention, in order to achieve the detailed operation process, the method comprises the following detailed steps:

[0025] 1. Since the deck cabin gaskets are processed after the deck cabin is hoisted and positioned, it is difficult to measure the gap between the deck cabin and the base of the deck cabin, and the panels corresponding to the deck cabin and the base of the deck cabin have double Due to the deformation of the cuboid, the contact area of the cuboid gasket cannot be guaranteed, or the on-site processing is carried out according to the actual situation on the site, but the deck tank needs to be lifted and lowered contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com