Testing apparatus and testing method for refrigerator circuit boards

A test device and circuit board technology, which is applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problem of occupying a large area of test site, and achieve the effect of saving power consumption and small program changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

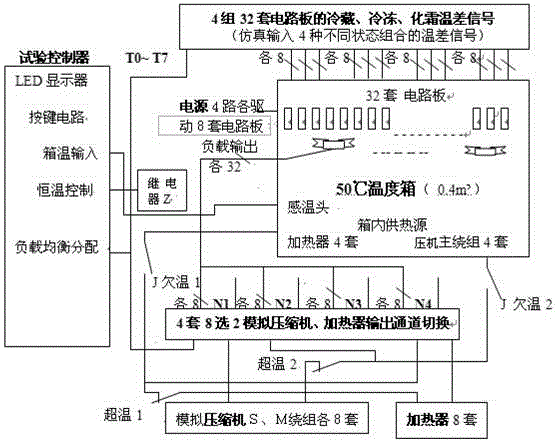

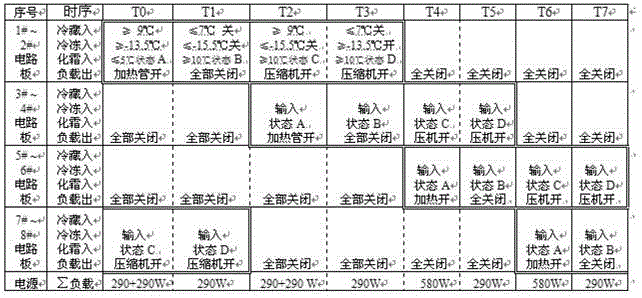

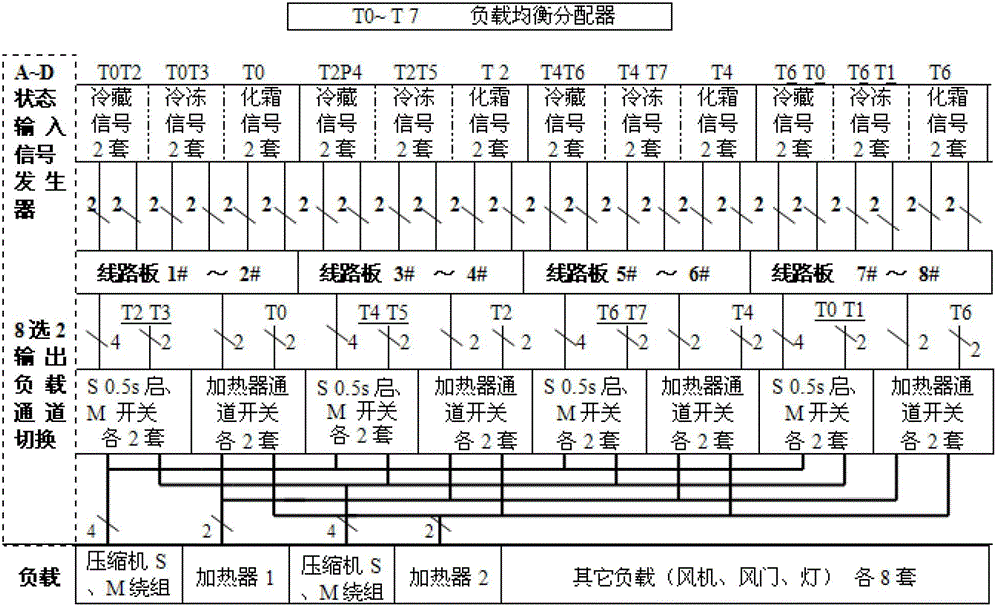

[0032] see figure 1 , The connection diagram of the circuit board test device consists of a test controller, 4 power supplies, 4 sets of 32 sets of circuit boards, temperature difference signal generators for refrigeration, freezing, and defrosting, 4 sets of 32 sets of circuit boards, 4 sets of 8 to 2 channel switching Circuit, 4 sets of 2 sets of analog compressors, heater load, 50°C temperature box composition:

[0033] The test controller includes test T0~T7 load balancing distributor, temperature measurement and constant temperature control of the temperature box, key circuit and LED display for testing load balancing distribution function, temperature measurement and constant temperature control function program input and temperature inside the temperature box display.

[0034] The 4-way power supply is correspondingly delivered to the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com