Heat-dissipating resistor and its heat-dissipating module

A heat dissipation module and heat dissipation technology, applied in the direction of resistors, resistor components, circuits, etc., can solve the problem that other parts cannot be tolerated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows.

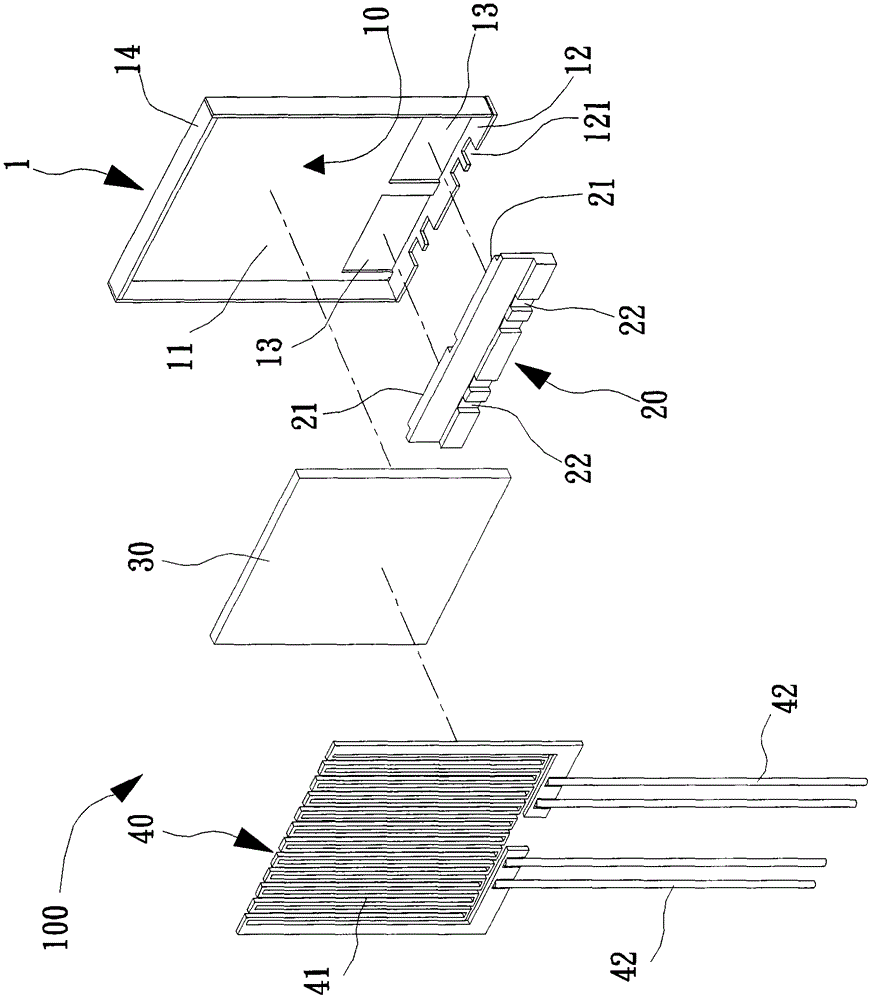

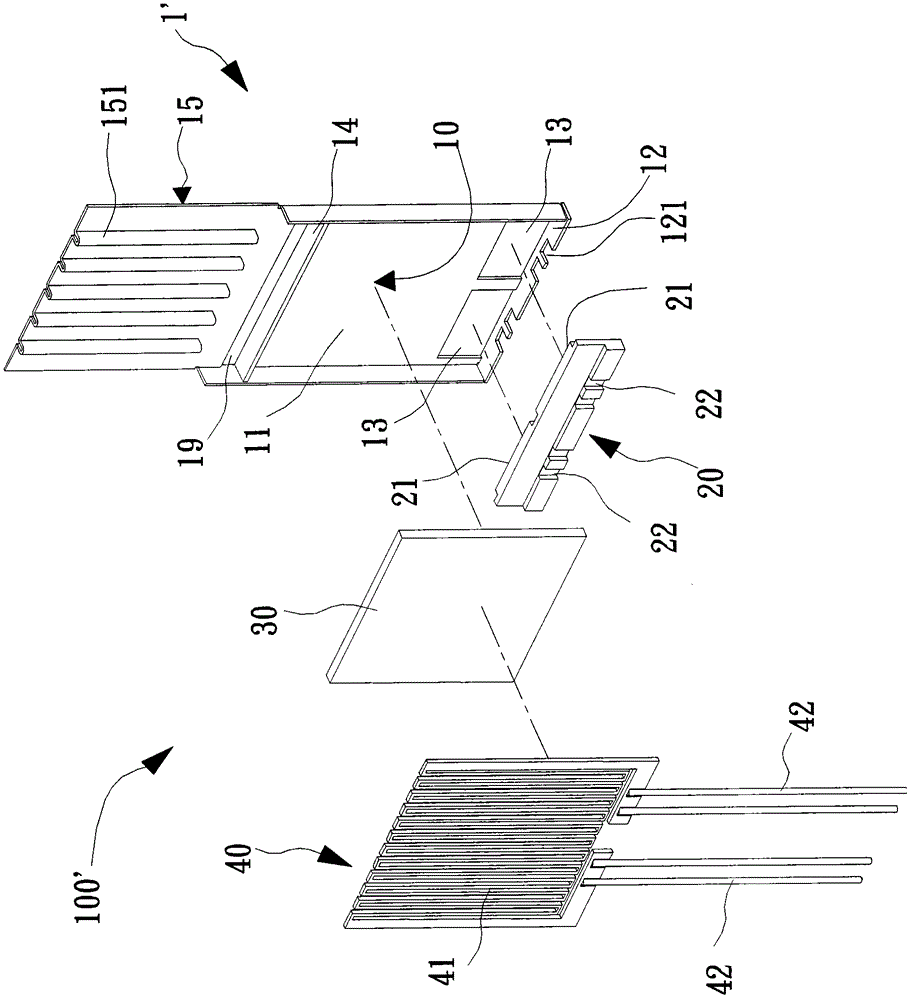

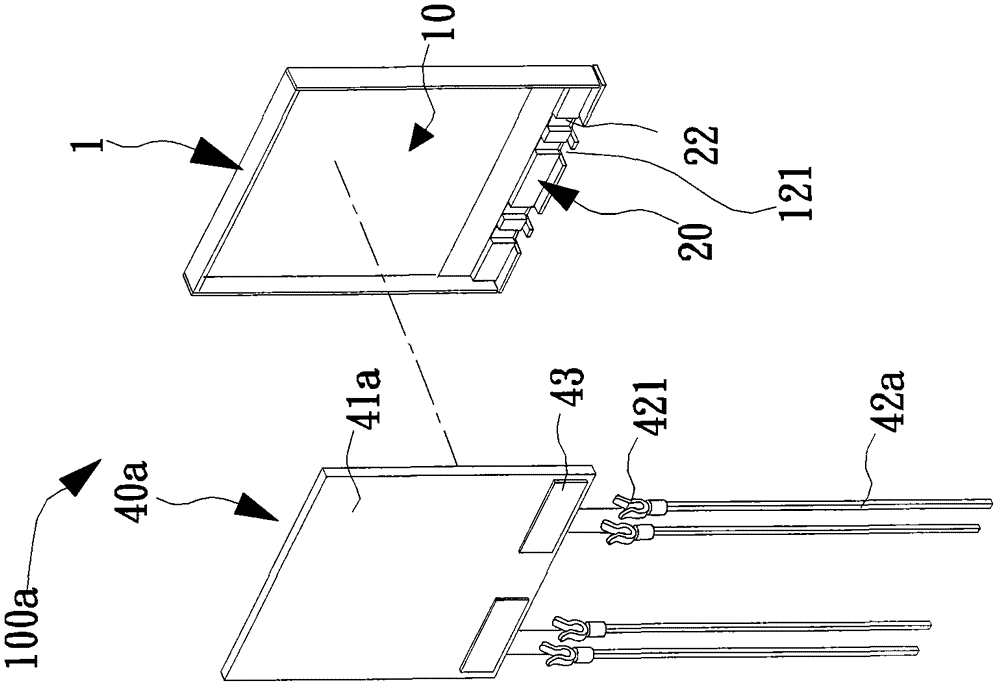

[0034] Please refer to figure 1 . The heat dissipation module 1 of the present invention includes: an accommodating portion 10 and at least one fixing hole 13 . The accommodating portion 10 includes a bottom surface 11 and a first side edge 12 , the first side edge 12 is perpendicular to the edge of the bottom surface 11 , and the first side edge 12 includes at least one notch 121 . The fixing hole 13 is located on the bottom surface 11 , and the fixing hole 13 is adjacent to the first side edge 12 .

[0035] Preferably, the heat dissipation module 1 further includes an insulating fixing base 20 . The insulating holder 20 includes at least one protruding portion 21 . The size and number of the protruding portion 21 correspond to the size and number of the fixing hole 13 , so that the protruding portion 21 is inserted into the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com