Glue injection method for automatic dispenser

A glue dispensing machine and glue injection technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of low operating efficiency, glue waste, and unsatisfactory glue dispensing effect, so as to save labor costs, glue injection, etc. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

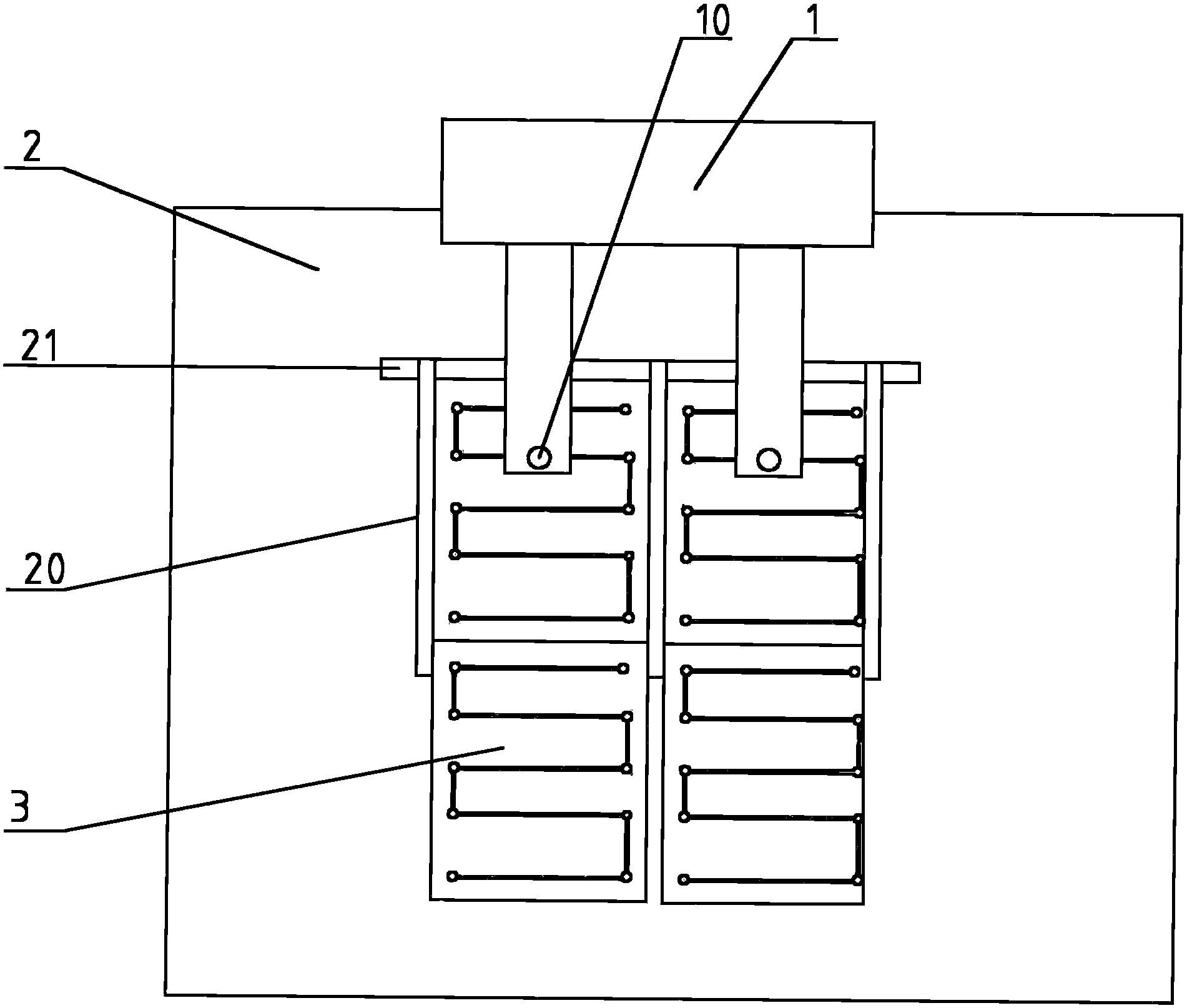

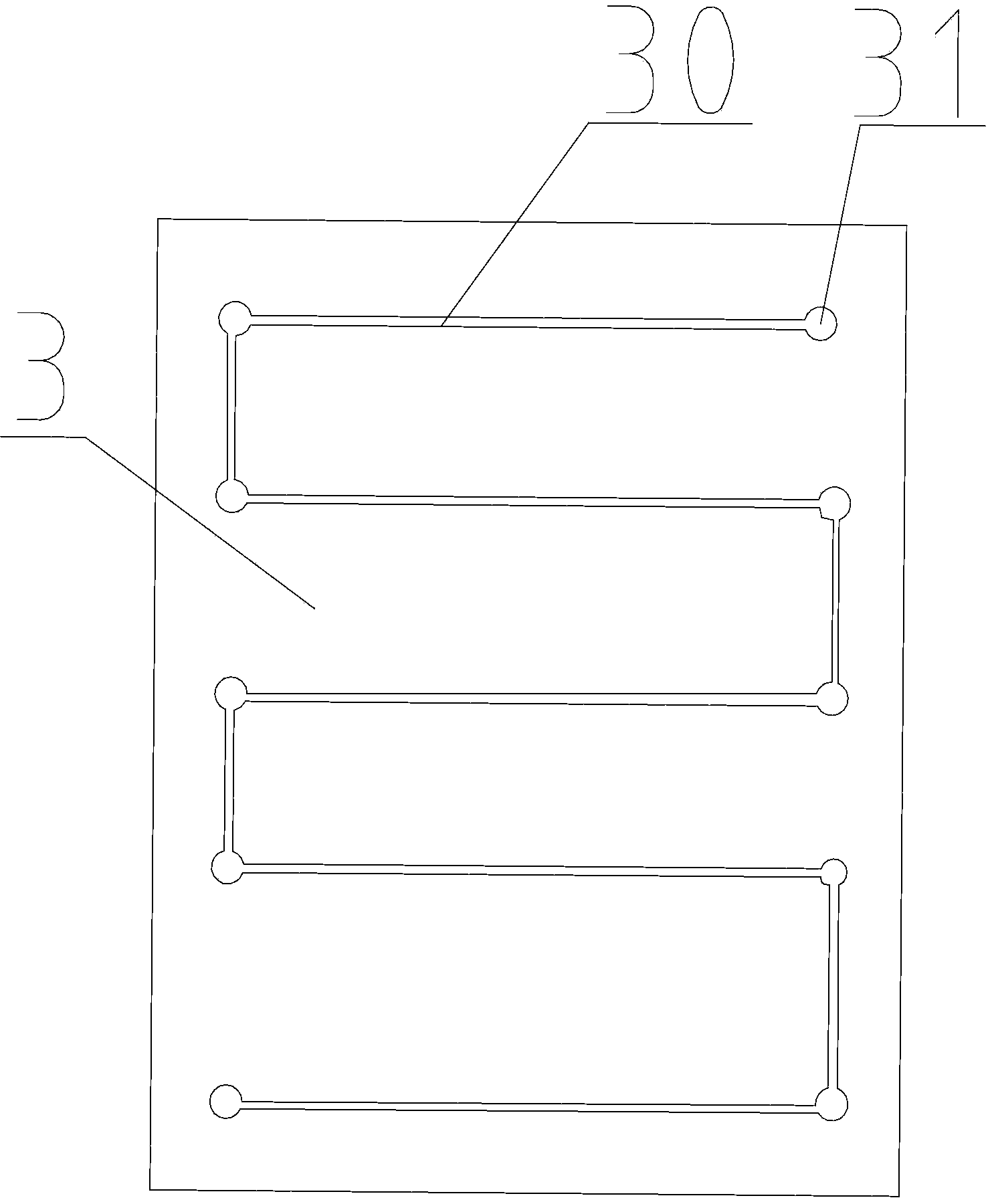

[0014] Such as figure 1 As shown, the glue injection method of the automatic dispensing machine of the present embodiment includes a feeding seat 2, at least two positioning bars 20 are arranged in parallel on the feeding seat 2, and a top bar 21 is also provided on the feeding seat 2, correspondingly Adjacent to the two positioning bars 20 and the top bar 21 form a dispensing area with three sides closed and one side open. A dispensing arm 1 is arranged above the feeding seat 2, and two dispensing heads are arranged side by side at the head of the dispensing arm 1. 10. Place the battery cover 3 to be injected in the glue dispensing area. The battery cover 3 is provided with a continuous S-shaped glue injection groove 30 to be injected, and the turning point of the S-shaped glue injection groove 30 is the glue to be injected. The stigma is assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com