Quick clamping mechanism

A clamping device, fast technology, applied in the direction of workpiece clamping devices, clamps, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is further illustrated below with examples, but the present invention is not limited thereto.

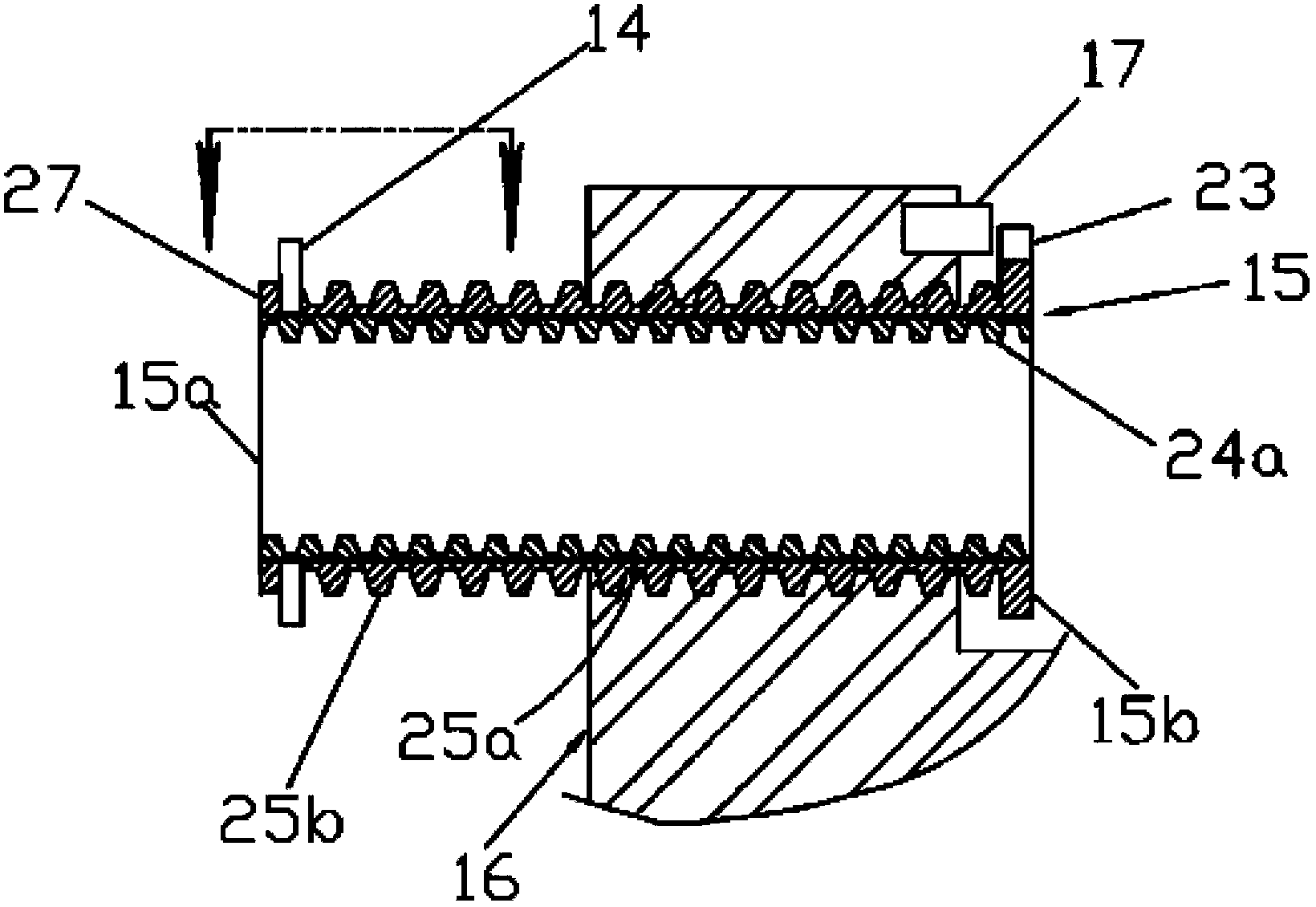

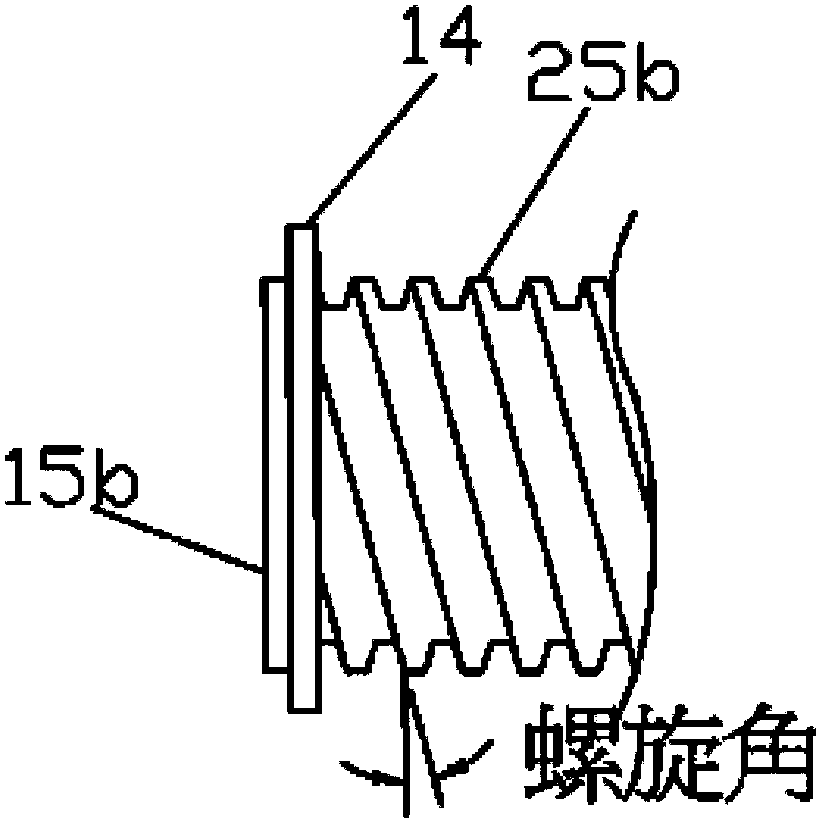

[0049] Mechanism Explanation: This description takes the double thread sleeve as an example to show the function of two sets of left and right double threads with opposite helix angles, and then continues to explain the situation when the two sets of helix angles are separated into two places.

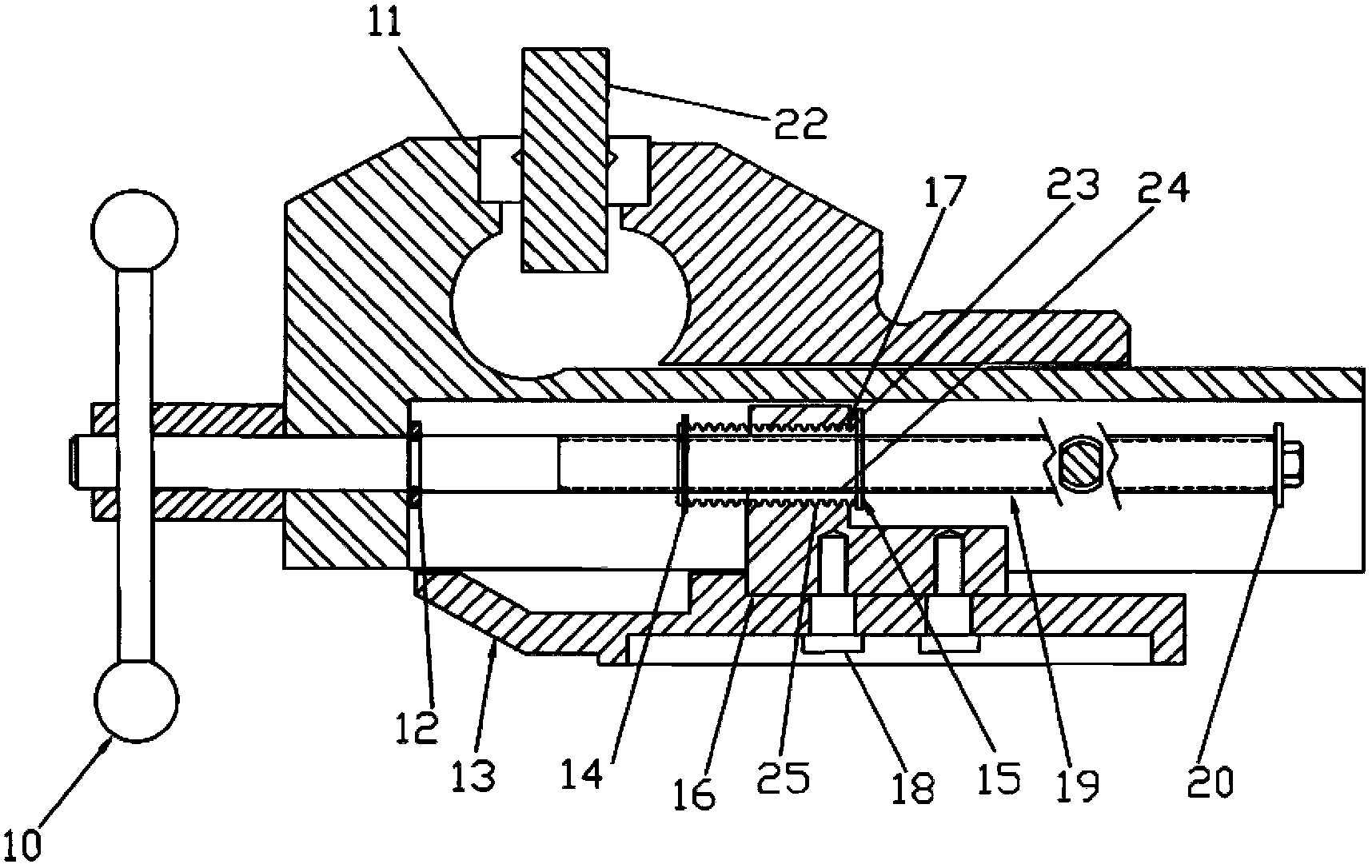

[0050] attached figure 1 It is shown that the whole quick vise uses two sets of thread sets with opposite left and right helix angles, one set is seated on the engaging thread set (24), and the other set is seated on the pressurizing thread set (25). These two sets of opposite helix angles are shown in the attached image 3 with attached figure 2 ,7 in. The engaging thread group (24) is called by the engagement of the internal thread (24a) of the double thread sleeve (15) and the external thread (24b) of the beveled screw (19); the pressurized thread group (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com