Method for positioning intersecting mouth space of pipe truss secondary rod

A positioning method and intersecting mouth technology, applied in the processing of building materials, marking of measurement points, construction, etc., can solve the problems of unfavorable design description and dimensioning of intersecting lines, and the inability to directly adopt plane design for intersecting lines, etc., to achieve The effect of shortening positioning time, high work efficiency, and meeting basic accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

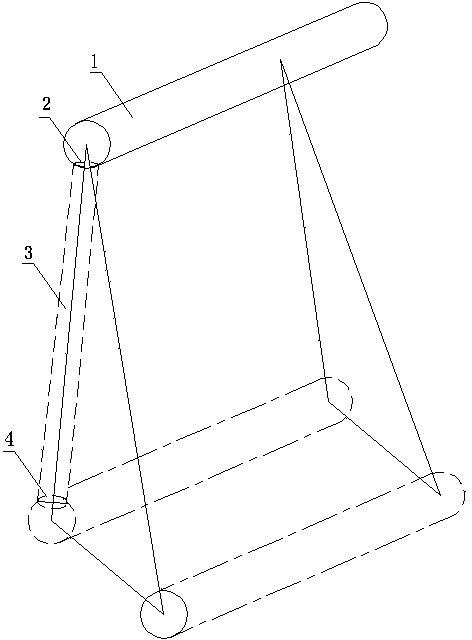

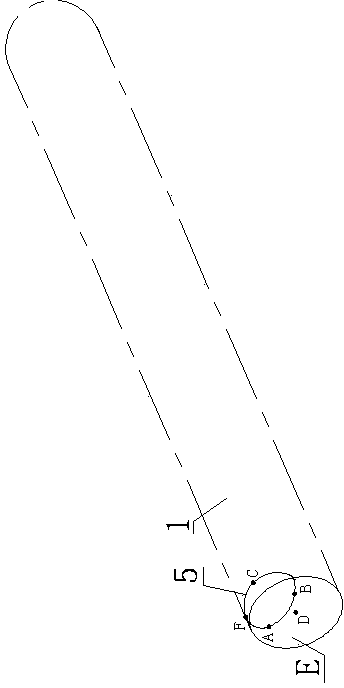

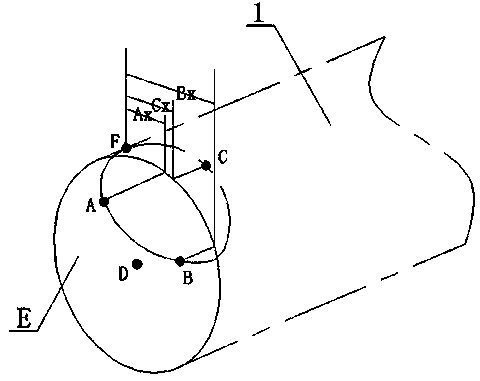

[0029] In this embodiment, taking the assembly of the intersecting joints of pipes and pipes in a typical pipe truss structure as an example, AUTOCAD is used to model the steel truss, and Boolean operations are performed on the modeled primary and secondary member models to form physical members. After approaching the simulation state, carry out imprint processing on the intersecting line of the intersecting outer surface of the primary and secondary members, leaving an intersecting line trajectory line, and determine any three feature points on the intersecting line trajectory line, as shown in figure 1 , locate the position of the secondary rod (steel pipe) 3 on the main rod (steel pipe) 1, the positioning method is: select three feature points on the upper port 2 and the lower port 4 of a secondary rod 3 to locate respectively, and the three feature points After the points are connected, an acute triangle structure is formed to locate the position of the secondary rod (steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com