Method for determining combustor vibration source position of combustion gas turbine

A determination method, gas turbine technology, applied in gas turbine engine testing, jet engine testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

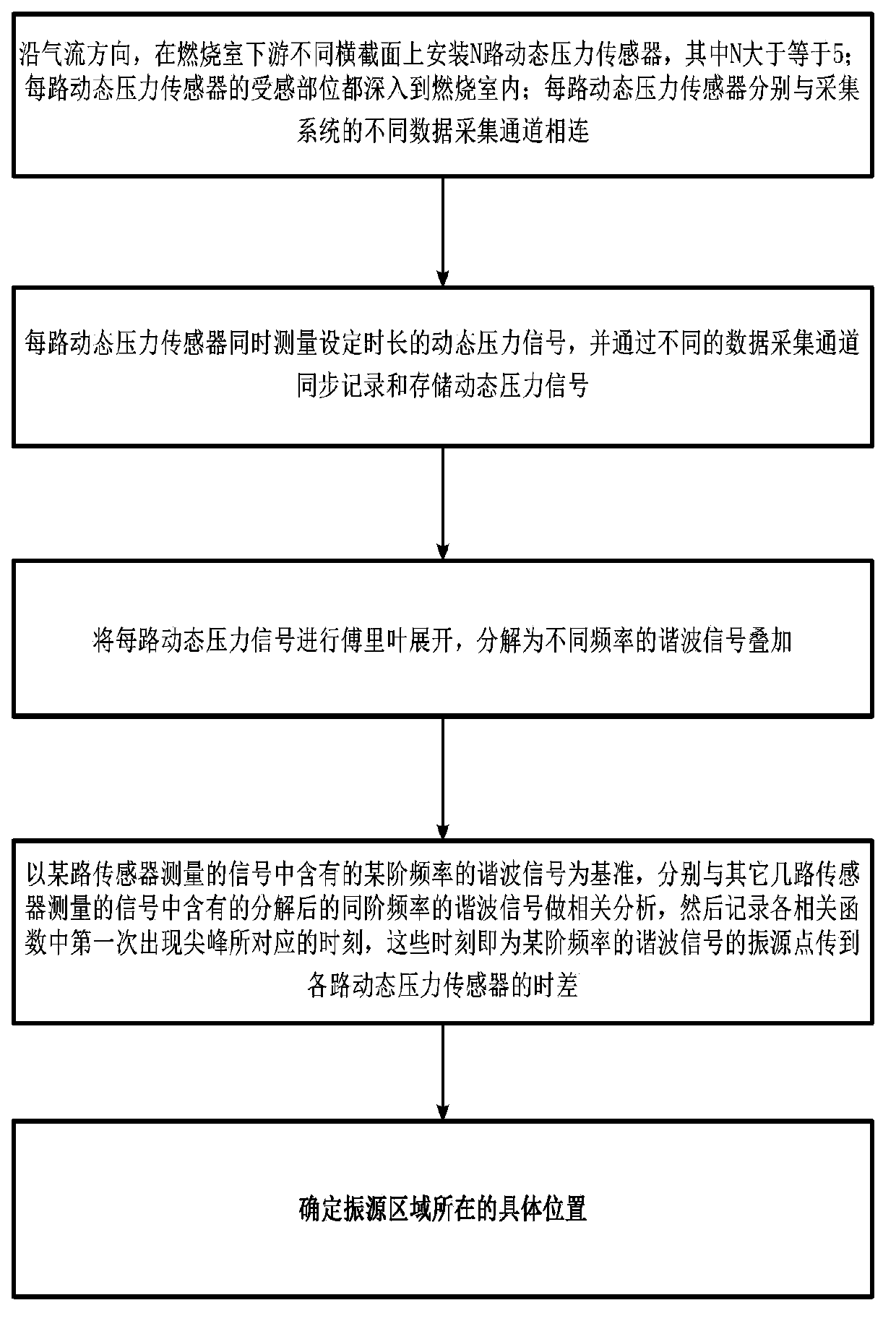

[0032] like figure 1 As described above, the present invention provides a method for determining the position of a vibration source in a combustion chamber of a gas turbine, the method including

[0033] Include the following steps:

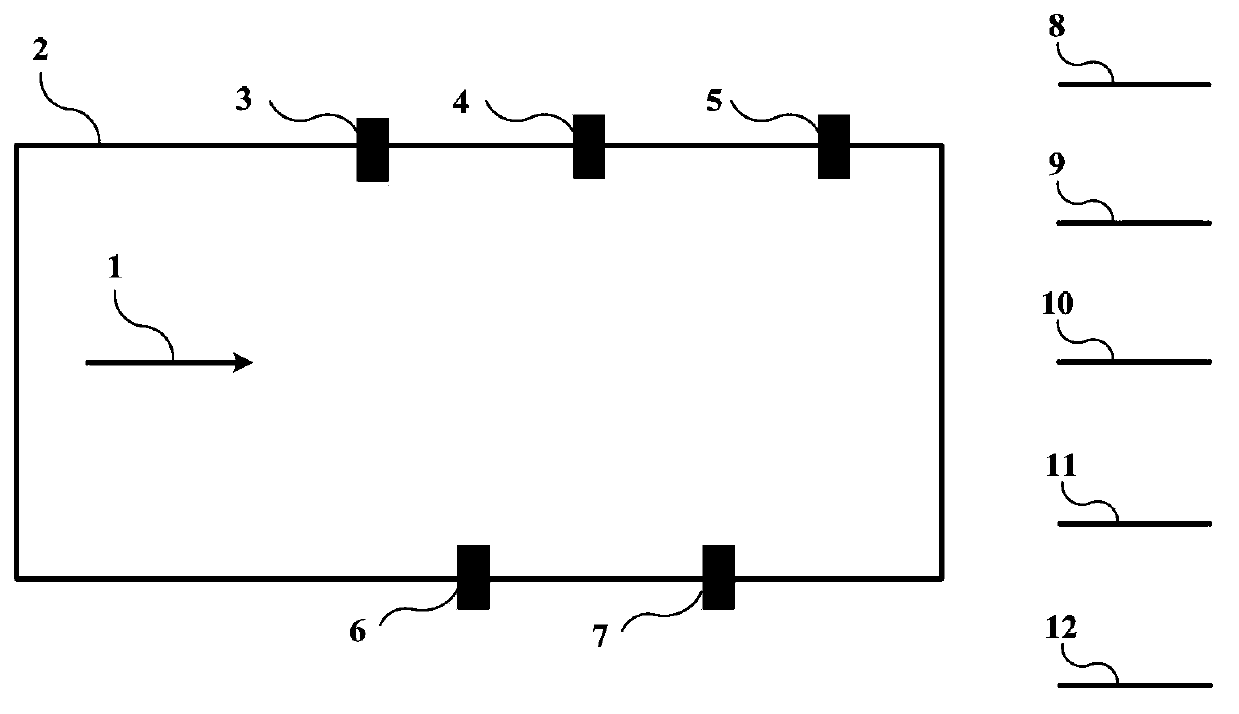

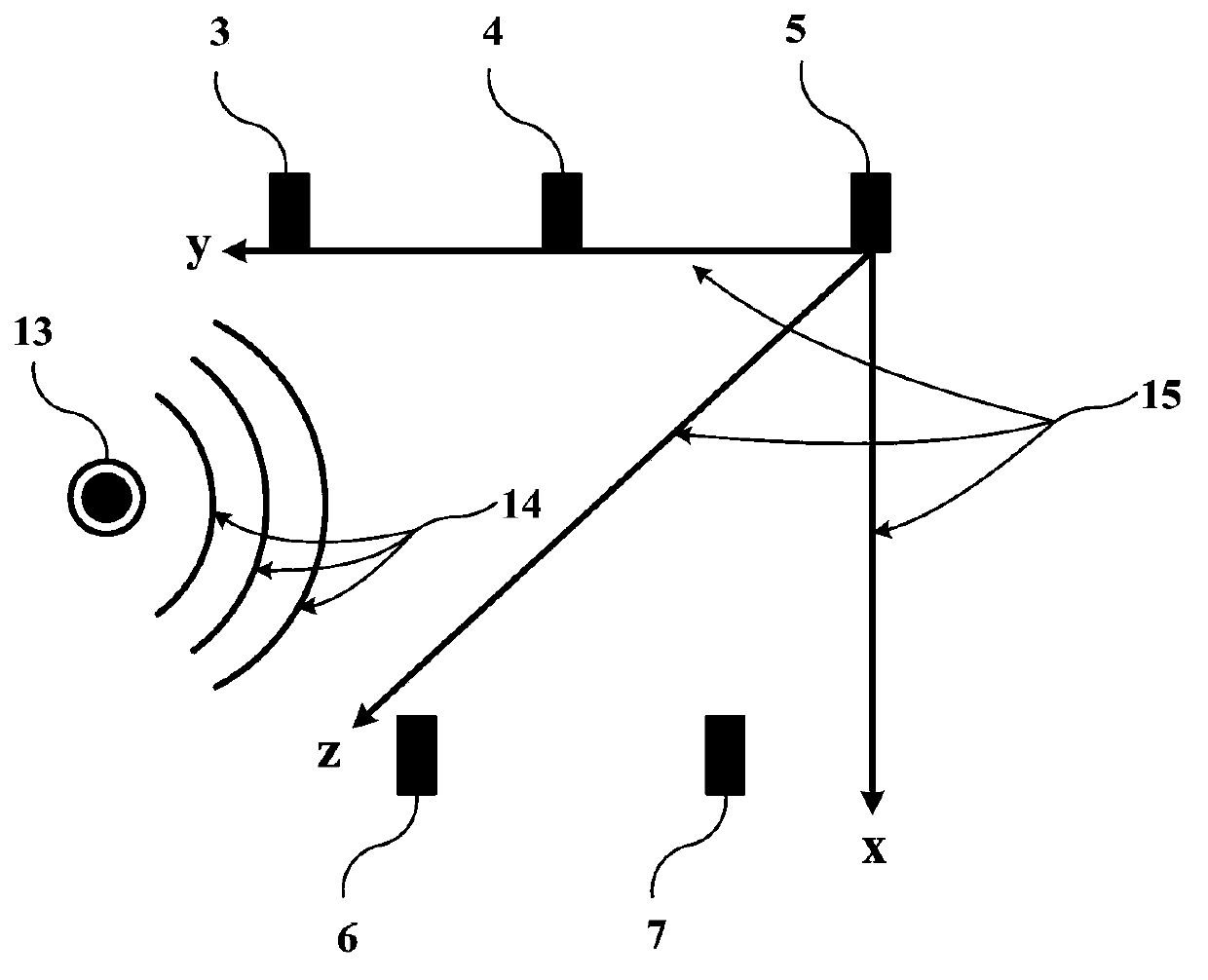

[0034] 1) Along the airflow direction, install N dynamic pressure sensors on different cross-sections downstream of the combustion chamber, where N is greater than or equal to 5; the sensing part of each dynamic pressure sensor goes deep into the combustion chamber; The different data acquisition channels of the system are connected;

[0035] 2) The N-channel dynamic pressure sensor simultaneously measures the dynamic pressure signal of the set duration t, and simultaneously records and stores the dynamic pressure signal through different data acquisition channels;

[0036] 3) Perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com