Parallel bundled cable normalizer

A technology for bundled cables and poles, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as slow work progress, heavy workload of parallel bundled cables, and poor return effect of parallel bundled cables. , to achieve the effect of reducing the workload, improving the return efficiency, and simplifying the return process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

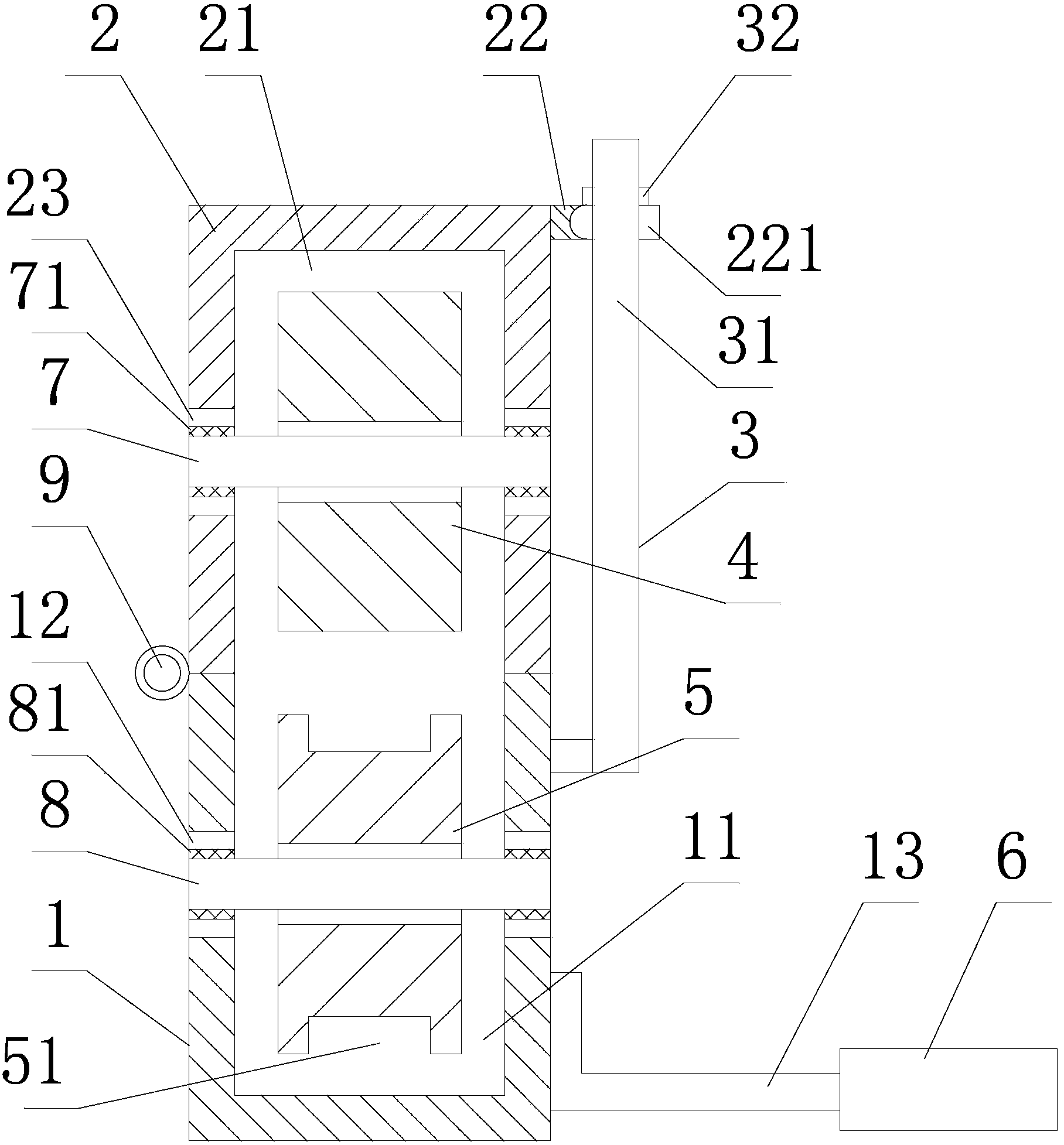

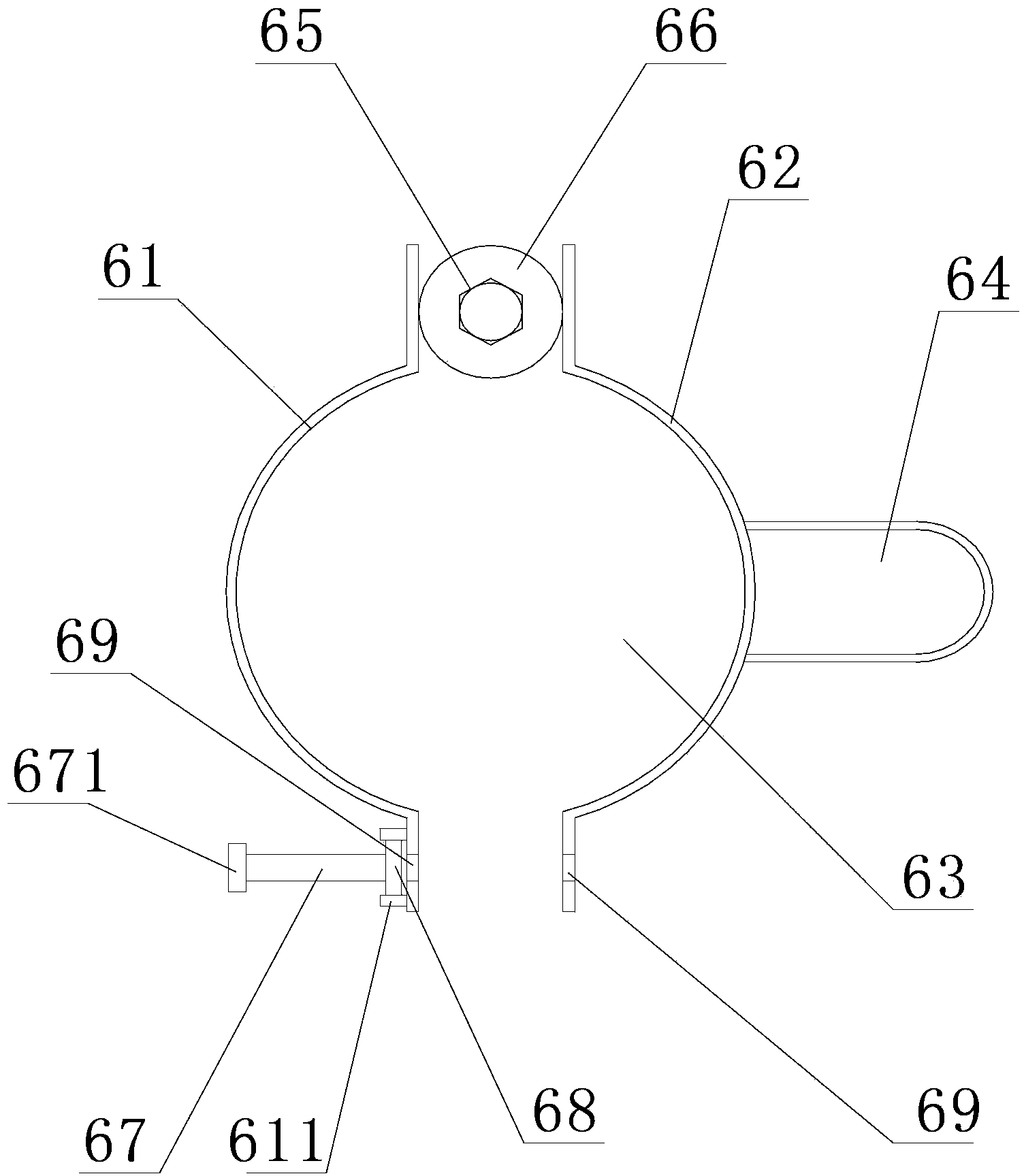

[0018] Such as figure 1 , figure 2 As shown, the parallel bundled cable squarer includes a lower bracket 1 provided with a first groove 11, an upper bracket 2 provided with a second groove 21, and one end of the upper bracket 2 is rotationally connected with one end of the lower bracket 1 , the other end of the upper bracket 2 is docked on the other end of the lower bracket 1, the lower bracket 1 is provided with a locking device 3 for locking the upper bracket 2 on the lower bracket 1, the second groove 21 A first fixed pulley 4 is movably connected, and a second fixed pulley 5 is movable in the first groove 11, and a gap is formed between the first fixed pulley 4 and the second fixed pulley 5 to facilitate the passage of parallel bundled cables. It also includes a clamping device 6 that can be installed on the pole. The clamping device 6 includes a first mounting plate 61 and a second mounting plate 62. One end of the second mounting plate 62 is connected to one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com