Lowe grease injection device used for vehicle bearing

A bearing and vehicle technology, applied in engine components, delivery pipes/joints, engine lubrication, etc., can solve problems such as uneven application and inconsistent injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

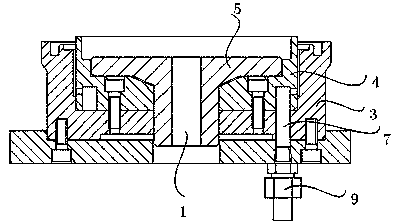

[0010] Combine below figure 1 , To further explain the present invention.

[0011] Such as figure 1 As shown, a grease injection device for vehicle bearings includes a tightening screw 1, which is sequentially sleeved with a bearing platform 5, a grease head inner base 4, and a grease head outer base 3, a grease head inner base 4 and a grease head. The cavity formed by the head outer base 3 is connected with the pipe joint 7 through the grease pipe 9, and a gap for circulating grease is provided between the grease head inner base 4 and the grease head outer base 3. The grease inlet pipe joint and the grease injection pipe flow into the cavity formed by the grease head inner base and the grease head outer base, and flow into the corresponding position of the bearing through the gap in the cavity.

[0012] In a preferred example, a sealing ring is provided between the grease head inner base 4 and the grease head outer base 3 to better prevent the grease from leaking from the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com