A Fast Nonlinear Predictive Control Method for Solid Oxide Fuel Cell Voltage

A solid oxide, non-linear prediction technology, applied in the direction of fuel cell control, fuel cells, fuel cell additives, etc., can solve the problems that nonlinear objects are difficult to achieve real-time predictive control, and the amount of calculation is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings.

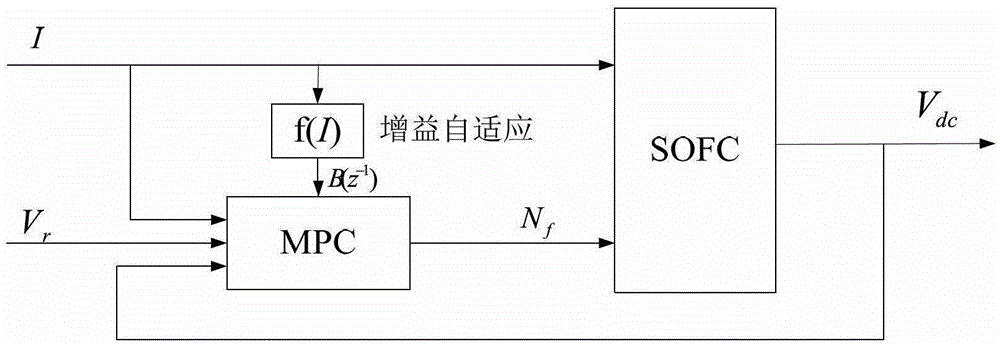

[0029] Such as figure 1 As mentioned above, the solid oxide fuel cell voltage fast nonlinear predictive control method proposed by the present invention adopts predictive control technology. In order to reduce the influence of system nonlinearity on control, the control system solves the real-time model parameters of the system online and uses them for predictive control algorithm calculation middle. In order to solve the problem of large amount of calculation in predictive control, combined with the nonlinearity of the solid oxide fuel cell mainly manifested in the object gain, in the model solution, only the model parameters related to the gain are solved, and a single-step predictive control with constraints is adopted. Simplifies predictive control calculations while taking into account the effects of fuel utilization limitations.

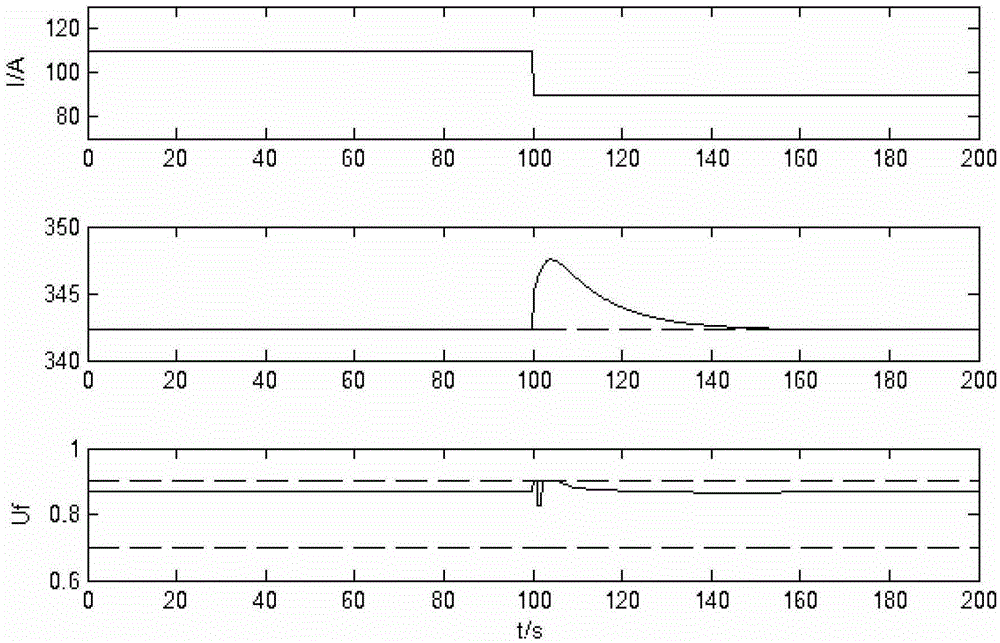

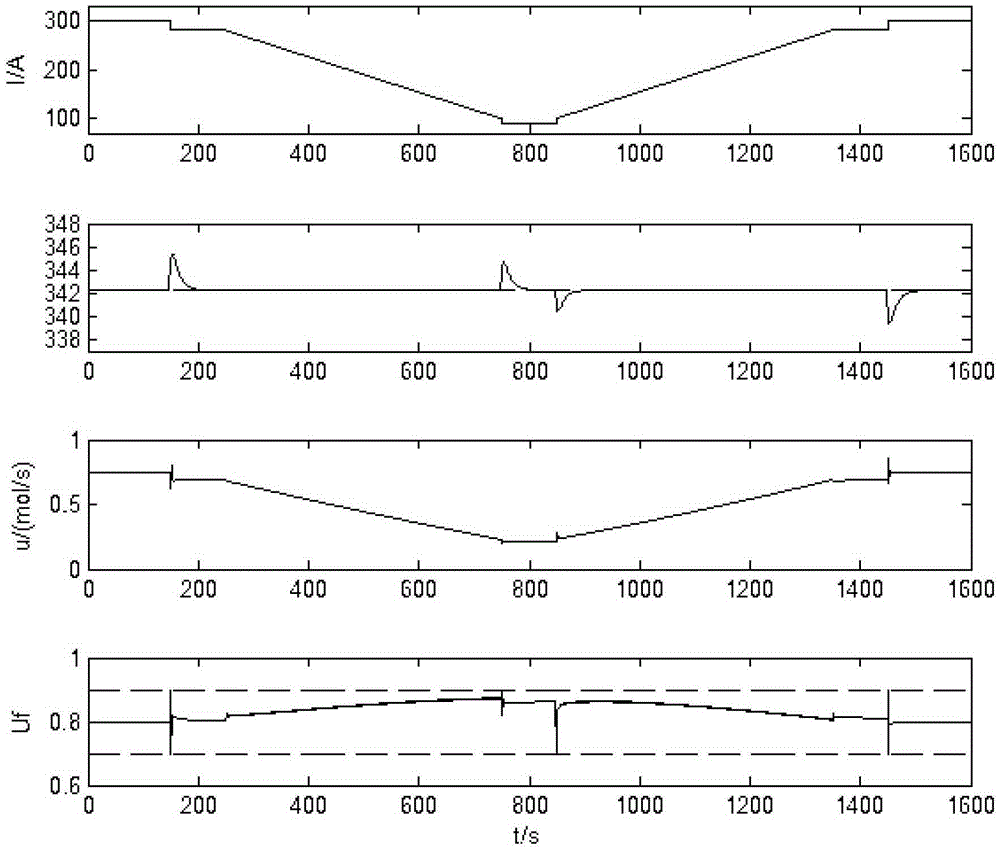

[0030] Below in conjunction wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com