Control system and method for reciprocating compressors

一种控制系统、压缩机的技术,应用在泵控制、液体变容式机械、机械设备等方向,能够解决组件重量降低低速旋转操作振动水平等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

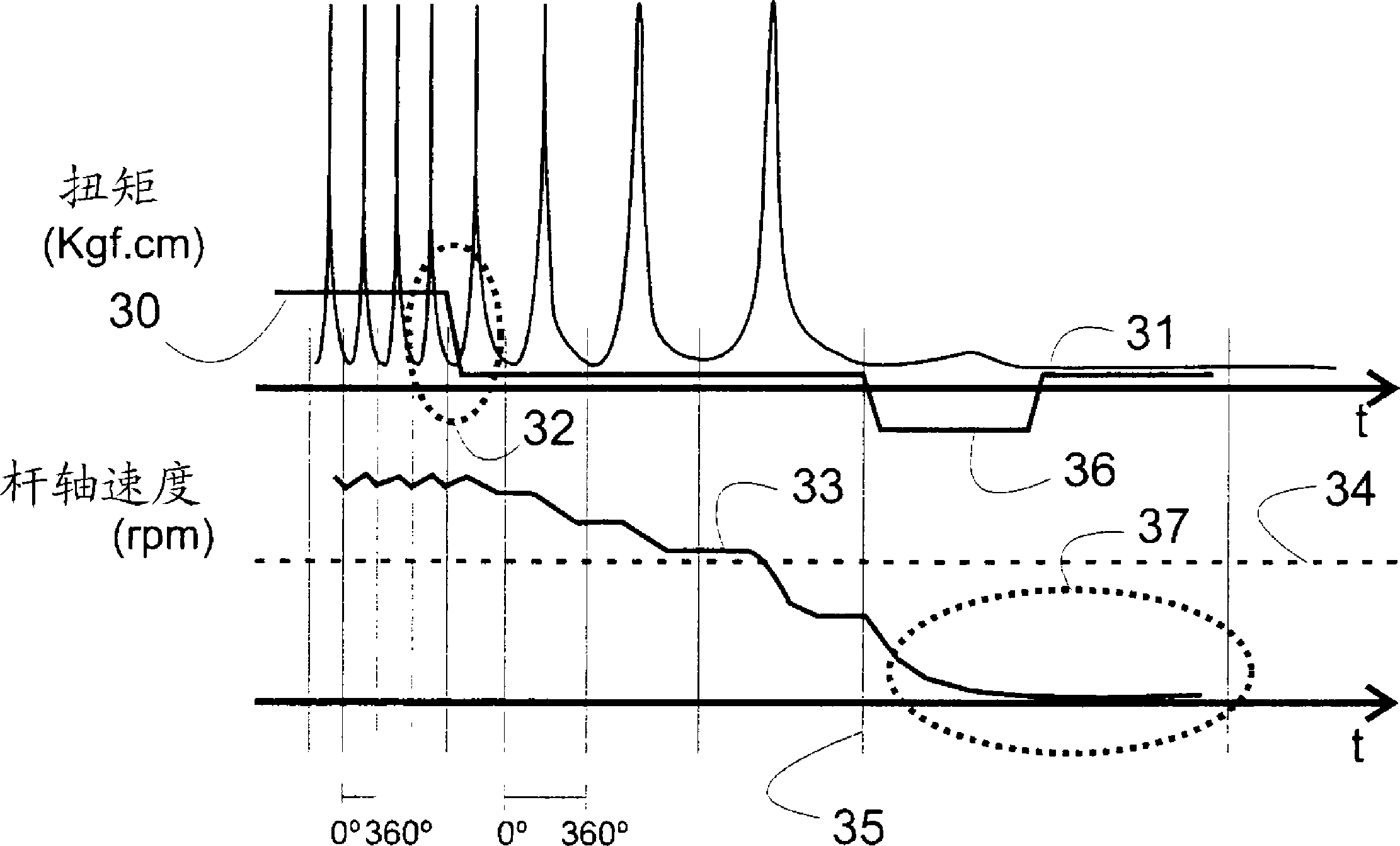

[0025] Such as figure 1 As shown, the cooling system comprises a reciprocating compressor 3 fed by an electrical power network 1 and having an electronic controller 2 able to control the operation of the reciprocating compressor 3 . The reciprocating compressor 3 drives the cooling gas in the gas circulation closed loop circuit 18 , thereby generating a cooling gas flow 78 within the circuit and directing this gas to the condenser 5 . After the condenser 5, the cooling gas passes through a flow cooling device 6, which may be, for example, a capillary tube. The gas is then directed to the evaporator 4 and then returned to the reciprocating compressor 3, restarting the gas circulation loop.

[0026] figure 2 Shows the focus of the subsystems inside the reciprocating compressor 3 formed by the housing 17 , the suspension spring 11 for damping the mechanical vibrations generated by the movement of the mechanical assembly 12 , the mechanical assembly is formed by a motor 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com