Conveyed bottle clamp for filling machine

A technology for conveying bottles and filling machines, which is applied in the field of conveying bottle clamps. It can solve the problems of not being able to clamp the mouth of the beverage bottle, placing the beverage bottle at an angle, and affecting the efficiency of filling, so as to achieve high filling efficiency and clamping The stable effect of beverage bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

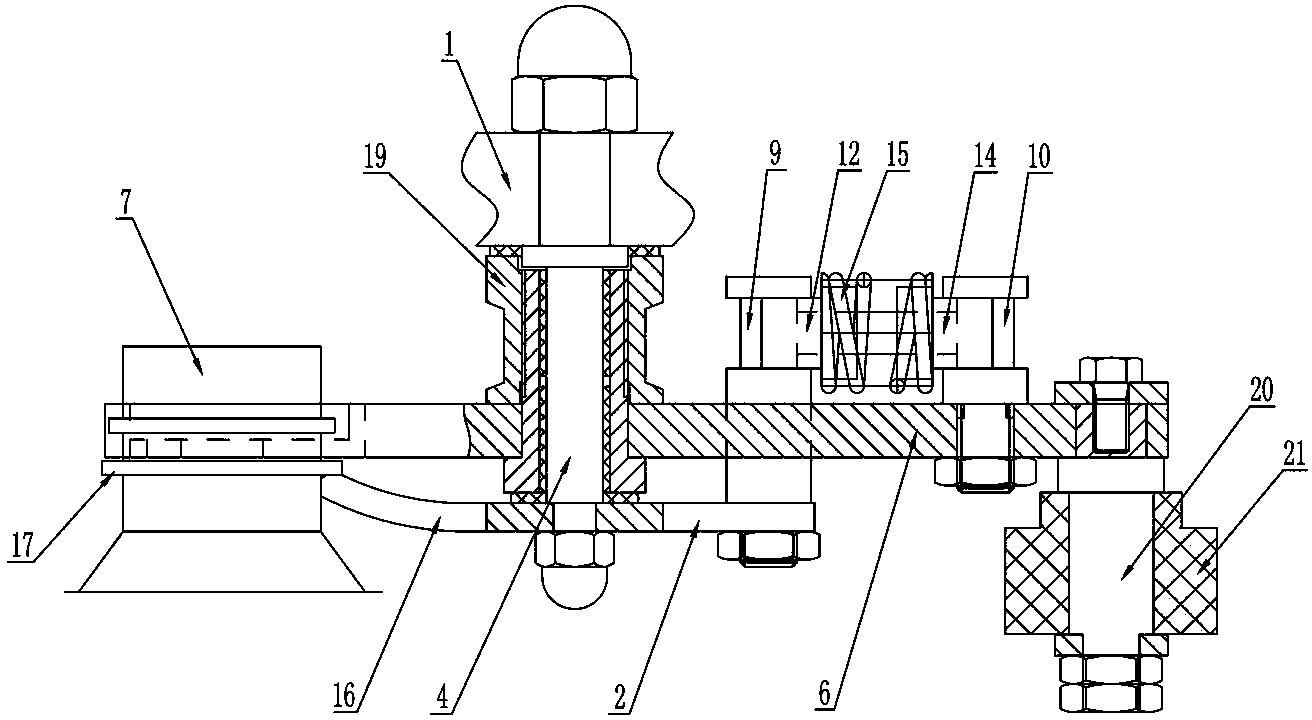

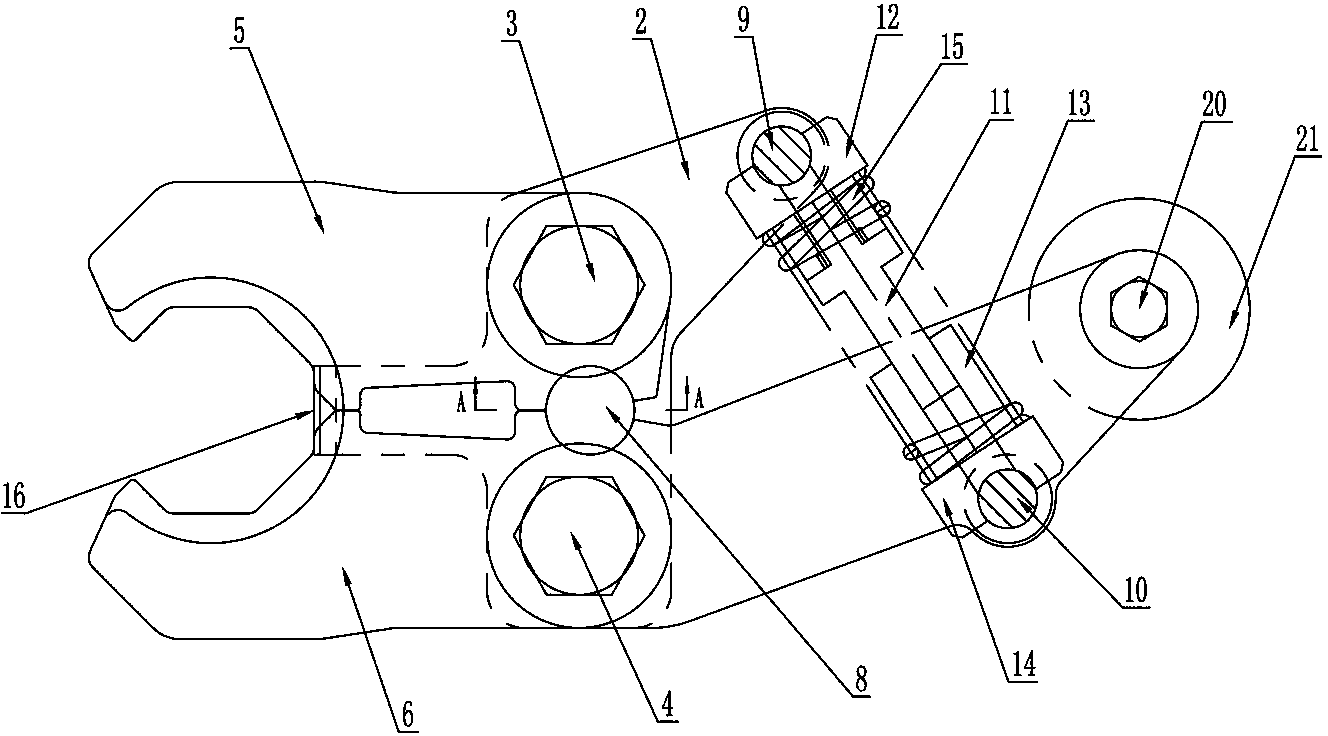

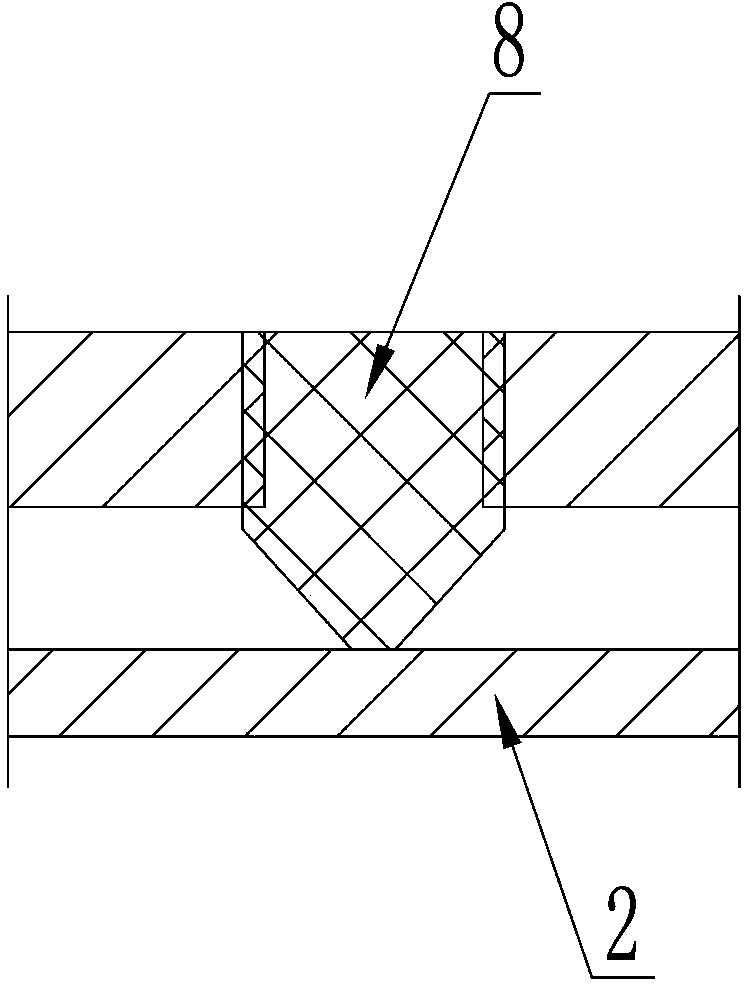

[0015] Such as figure 1 , figure 2 , image 3 As shown, the conveying bottle clamp on the filling machine includes a bottom plate 2 installed under the mounting plate 1 through the first pin shaft 3 and the second pin shaft 4, and the first clamp is movable on the first pin shaft 3 Holding arm 5, the second pin shaft 4 is movably provided with a second clamping arm 6, the clamping end of the first clamping arm 5 and the clamping end of the second clamping arm 6 can be in a relative clamping shape to clamp the beverage Bottle mouth 7; on the inner wall of the first clamping arm 5, an arc-shaped opening located above the base plate 2 is provided, and on the inner wall of the second clamping arm 6, a circular opening located above the base plate 2 is also provided. Arc-shaped openings, two arc-shaped openings are set opposite to each other to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com