Triaxial multiple coal and gas outburst test method

A test method and multiple outburst technology, applied in the field of triaxial coal and gas multiple outburst tests, can solve the problem that the size of the briquette specimen is large, as short as a few minutes, as long as ten hours, or even several days; Prominence, long test preparation period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

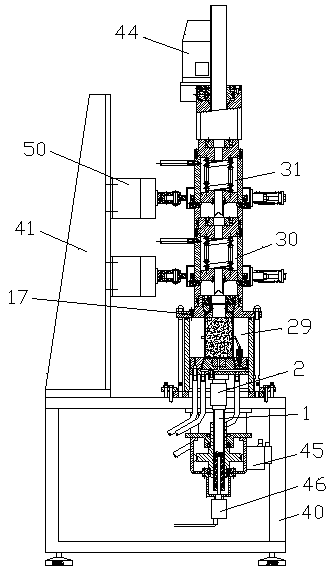

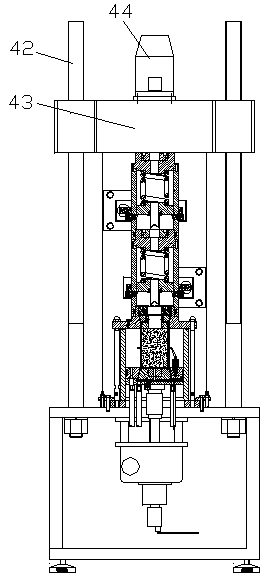

[0033] Triaxial coal and gas multiple outburst test method, in which a test device is used, such as figure 1 ,2 As shown, the test device includes a frame 40 , a support 41 , a primary pressure chamber 29 , a primary pressure chamber 30 and a secondary pressure chamber 31 . Bearing 41 is installed on the frame 40, and column 42 is vertically set respectively on both sides of frame 40, and a moving crossbeam 43 and moving crossbeam drive motor 44 are set between two columns 42, and moving crossbeam 43 slides with column 42 Cooperate.

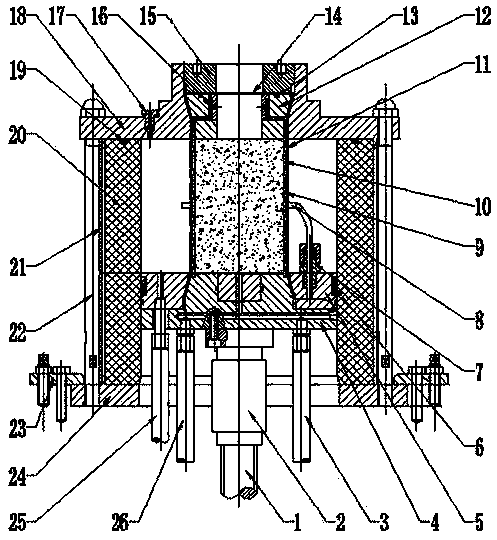

[0034] The structure of the main pressure chamber is as follows image 3 , 4 As shown in and 5, the main pressure chamber 29 includes a confining pressure chamber base 24, a steel cylinder 20, a confining pressure chamber upper cover 18, a protruding opening sealing taper sleeve 12, a sealing aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com