Submarine cable sealing device

A submarine cable and sealing device technology, applied to the cable inlet sealing device and other directions, can solve the problems that the cable and the sealing material are not easily separated, the sealing end cannot be reused, etc., and achieve the effect of improving resource utilization, avoiding pressure, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

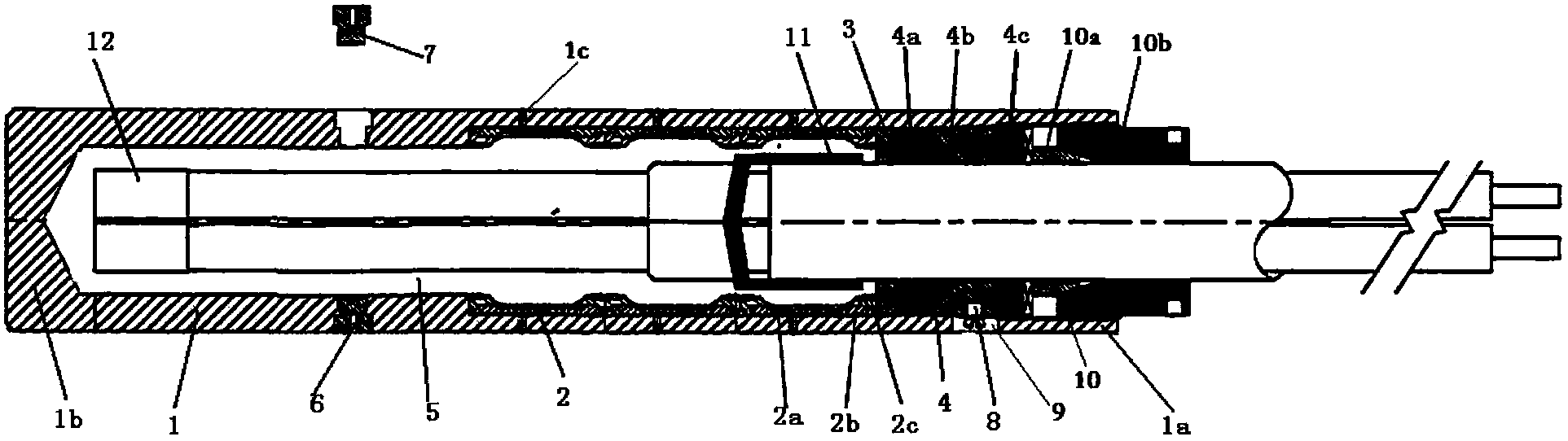

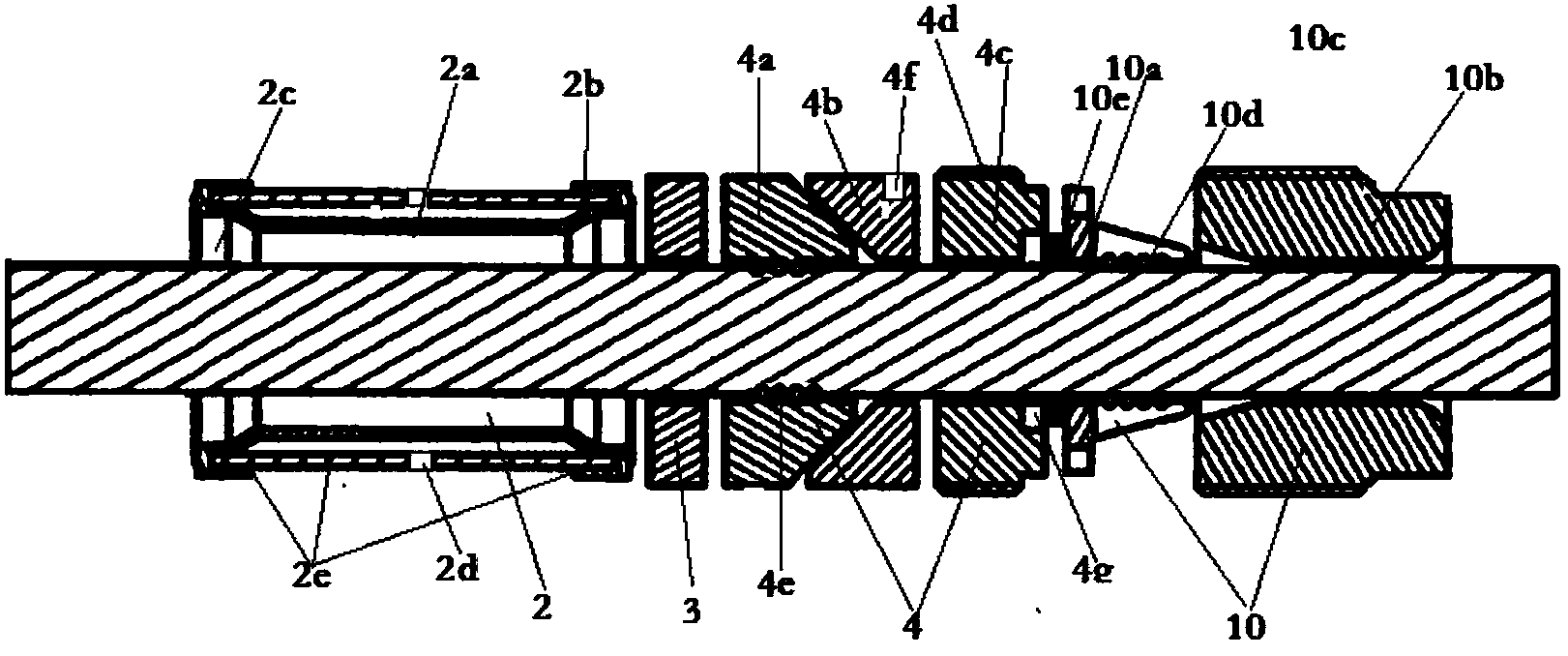

[0024] like figure 1 , figure 2 As shown, the present invention discloses a submarine cable sealing device, comprising a protective sleeve 1 , a sealing component 4 and at least one pressure compensation component 2 . The protective sleeve 1 includes an open end 1a for the end of the cable to penetrate; the other end can be an open end 1a or a closed end 1b, but it must be able to ensure that the submarine cable is sealed to avoid seawater infiltration, The other end in this embodiment is the closed end 1b.

[0025] The sealing assembly 4 is disposed inside or outside the open end 1a of the protective sleeve 1 to seal the open end 1a, and is preferably disposed inside the protective sleeve 1 in this embodiment. The sealing asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com