Food frying machine allowing gradual replacement and use of oil

A food and frying machine technology, applied in the direction of oil/fat baking, etc., can solve the problems of high energy consumption, achieve the effects of improving health, short update time, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

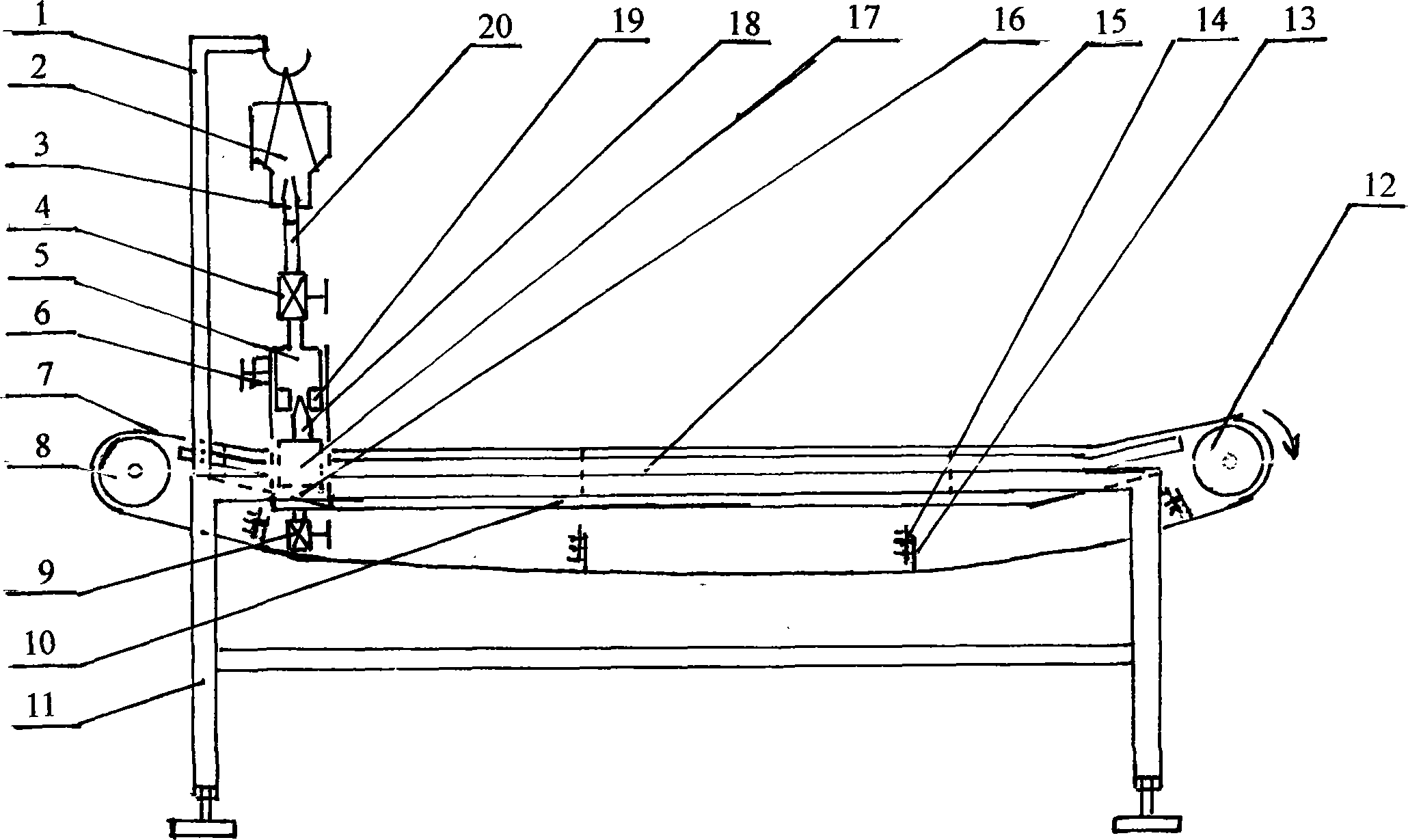

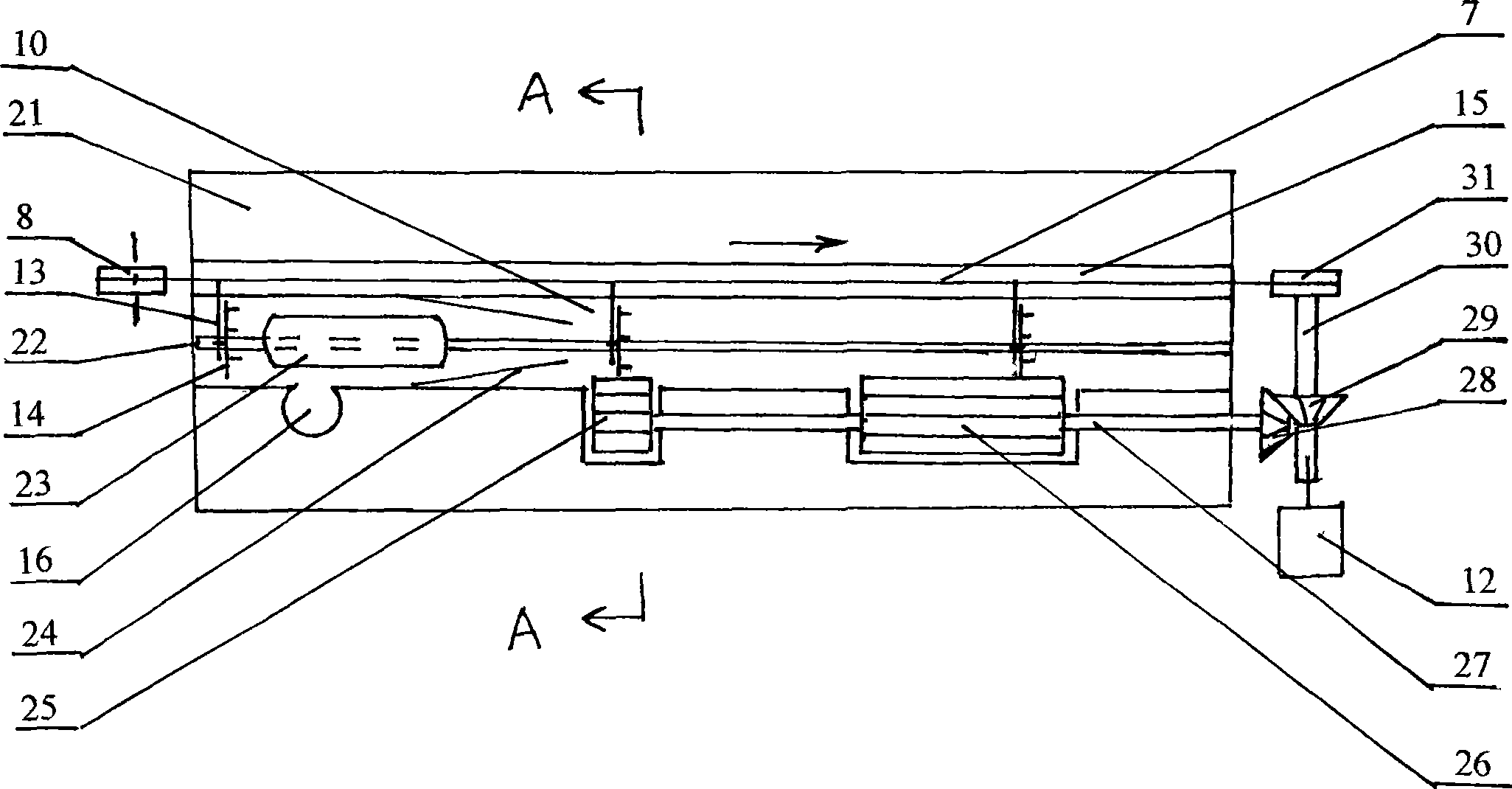

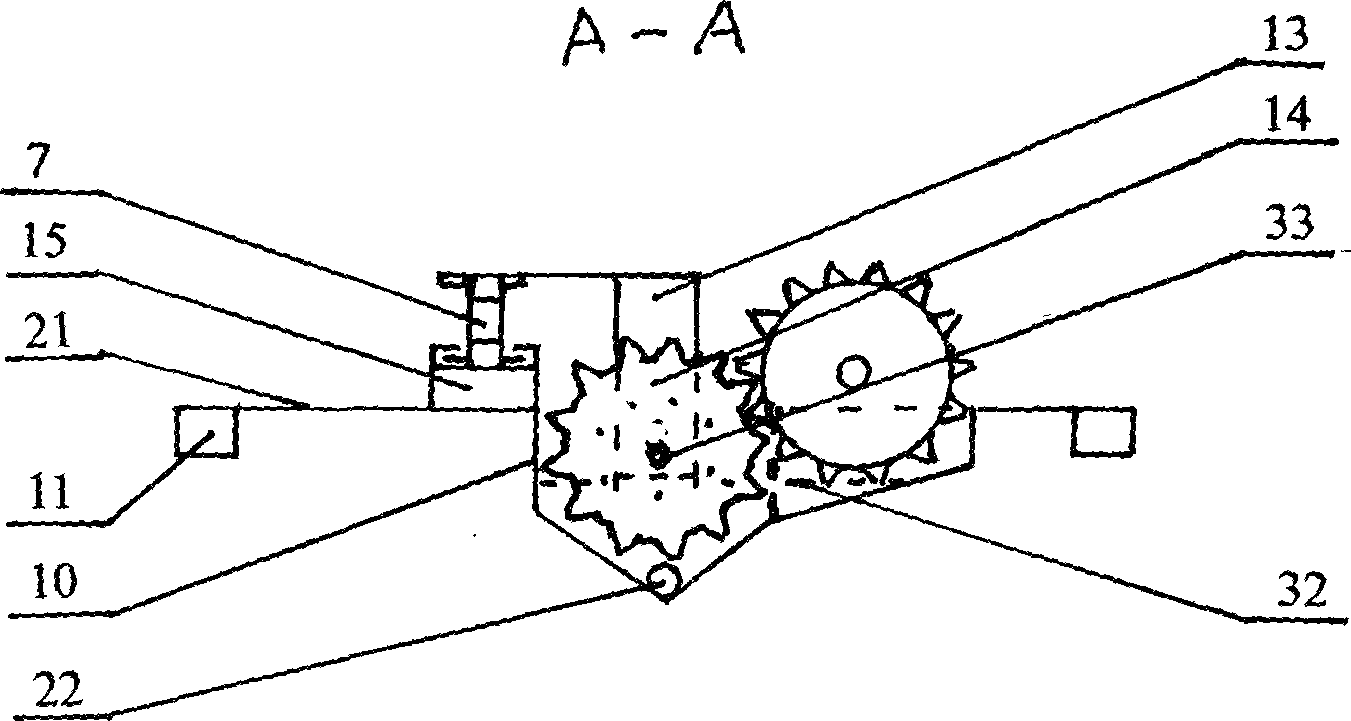

[0006] Specific implementation mode one: (see Figure 1 ~ Figure 3 ) This embodiment consists of a bracket hook 1, a tapered pipe 3, an adjustment pipe 5, a fastening device 6, a four-bend chain 7, a driven sprocket 8, an oil tank 10, a frame 11, a motor 12, a toggle plate 13, a belt Needle tooth wheel 14, chain track 15, float chamber 16, float 17, conical column 18, oil-resistant rubber ring 19, oil-resistant hose 20, platform 21, electric heating tube 22, spring leaf 24, one-time turning tooth wheel drum 25 , Overturning the tooth wheel drum 26 multiple times, the wheel drum shaft 27, the wheel drum shaft bevel gear 28, the drive shaft bevel gear 29, the drive shaft 30, the drive sprocket 31, the oil surface 32, the connecting shaft 33, and the arc bottom oil tank 34. Arc cooling plate 35, wheel drum 37, soft spring sheet 38, casing 39, bushing 40, shaft 41, chain 42, sprocket wheel 43, needle disc 44, connecting oil pipe 45, single drive motor 46, heat preservation Layer ...

specific Embodiment approach 2

[0007] Specific implementation mode two: (see Figure 1 ~ Figure 4 ) The round or cylindrical fried object 36 of the present embodiment is placed in the oil tank 10, the upper double bend of the four-bend chain 7 is fixed with a toggle plate 13, the wheel drum shaft 27 is fixed with a wheel drum 37, and the wheel drum 37 Soft spring sheet 38 is fixed. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0008] Specific implementation mode three: (see Figure 1 to Figure 5 ) The difference between this embodiment and the second embodiment is that an arc-shaped bottom oil tank 34 is arranged in the middle of the platform 21, and an arc-shaped cooling plate 35 is arranged outside the arc-shaped bottom oil tank 34, and the electric heating tube 22 is fixed on the arc-shaped heat dissipation plate 35. Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com